Desorption Electrolysis System

Blackstone International Company Limited- Type:Gold Separation Equipment

- Certification:ISO9001:2000

- Energy Saving:Energy Saving

- Condition:New

Base Info

- Model NO.:Desorption electrolysis system

Description

Technical Parameter of Gold Electrolyzer

Model

Volume

m3

Number of cathode plates

Number of anode plates

Homopolar spacing

mm

Temperature

ºC

Voltage

V

Electric current

A

Remarks

DJC0.2

0.2

9

10

105

90~95

0~6

0~1000

Resin desorption

DJC0.4

0.4

7

8

105

90~95

0~6

0~1000

DJC0.6

0.6

11

12

105

90~95

0~6

0~1000

DJC0.8

0.8

15

16

105

90~95

0~6

0~1000

DJC1

1

20

21

105

90~95

0~6

0~1000

DJC0838

0.838

24

25

80

65±5

1.5~3

300~350

Technical Parameter of Electrolyte Storage Tank

Model

Specification

Filtration Volume

m3

Weight

kg

JDYC650

φ400×1300

0.22

126

JDYC900

φ900×900

0.57

229

JDYC1000

φ1000×1200

0.94

252

JDYC1200

φ1200×1200

1.36

308

JDYC1350

φ1350×1400

2

368

JDYC1500

φ1500×1500

2.65

558

JDYC2250

φ2250×1500

5.96

951

JDYC2

2280×1188×888

2

490

Filter Technical Parameter

Model

Filtration Volume

m3

Working Temperature

ºC

Working Pressure

Pa

Weight

kg

JDG600

2

135

≤0.5

349

Technical Parameter of Gold Carbon Storage Tank

Model

Specification

Tank Thickness

mm

Weight

kg

JDCC600

φ600×1050

6

125

JDCC900

φ900×1805

6

288

JDCC1000

φ1000×2005

6

402

JDCC1200

φ1200×2390

6

360

Structure

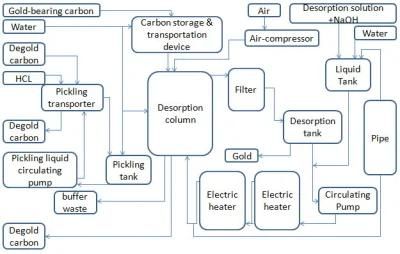

The desorption electrolysis system adds anions easily adsorbed by activated carbon to the desorption system, thus replacing Au(CN)2-to realize gold desorption. The precious liquid obtained by desorption of gold-loaded carbon is recovered by ionization method to obtain solid gold.

The desorption electrolysis device is mainly composed of desorption and electrolysis. The process of desorption and electrolysis is separated so that the solvent is carried out in a comprehensive desorption tower. The noble liquid electrolysis is completed in an independent electrolytic cell. The four processes of solvent desorption, noble liquid heating, solvent condensation and solvent recovery are centralized in a comprehensive desorption tower, and the noble liquid obtained by solvent vapor desorption of gold-loaded carbon is concentrated. The crude gold is obtained by electrolysis in a separate electrolytic cell through a pipeline, and then the finished gold is purified.

Desorption electrolysis system

Model

Capacity (t/d)

Ore Grade

(g/t)

Parameter

GJD-200

<150

2-8

Working Temperature:150ºC

Analytical solution (Na0H)PH:≥13.5

Dosorption Tank Pressure:0.5(Mpa)

Electrolytic cell pressure:0.45(Mpa)

GJD-300

150-300

2-8

GJD-500

300-500

2-8

GJD-700

GJD-1000

500-1000

2-8

GJD-1500

GJD-2000

1000-2000

2-20

GJD-2500

GJD-3000

GJD-3500

2000-3000

2-20

GJD-4000

GJD-5000

GJD-8000

3000-5000

2-20

Electric Heating Technology

Model

Working Temperature

ºC

Working Medium

Heat Power

kw

Voltage

V

Weight

kg

Remarks

JDDR6

40

NH4SCN

2×3

380

80

Resin desorption

JDDR18

98

1%NaOH+2%NaOH

6×3

380

JDDR24

98

1%NaOH+2%NaOH

8×3

380

147

JDDR36

98

1%NaOH+2%NaOH

6×6

380

JDDR48

98

1%NaOH+2%NaOH

8×6

380

138

Desorption Column

Model

Volume

m3

Working Pressure

Pa

Working Temperature

ºC

Working Medium

φ300×2000

0.14

Normal

95~98

NaOH 2%+NaOH 1%

φ450×2000

0.4

Normal

95~98

φ500×2500

0.49

Normal

95~98

φ500×3000

0.55

Normal

95~98

φ500×3720

0.7

Normal

95~98

φ518×3880

0.82

Normal

95~98

φ600×3000(2500)

0.85(0.71)

Normal

95~98

φ600×4300

1.2

Normal

95~98

φ700×3000

1.08

Normal

95~98

φ700×3800(2800)

1.585(1.08)

Normal

95~98

φ800×4000

2

Normal

95~98

φ900×4200

3

Normal

95~98