Peripheral Transmission Thickener

Blackstone International Company Limited- Type:Thickening & Dewatering

- Certification:ISO9001:2000

- Energy Saving:Energy Saving

- Condition:New

Base Info

- Model NO.:Peripheral Transmission Thickener

Description

Basic Info.

Model NO. Peripheral Transmission ThickenerProduct Description

Peripheral Transmission Thickener

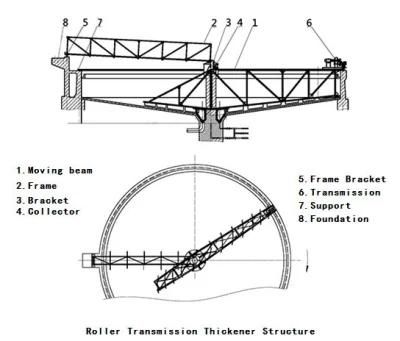

[Introduction] It is divided into two forms, peripheral roller drive and peripheral rack drive.

[Capability] 88-3400t/d

[Application] It is mainly used for dewatering treatment of wet separation and concentrating in mineral processing, as the first stage of concentrated dewatering. Generally set between the cleaning and filtering equipment, sometimes used for dehydration before the cleaning, but also used in the chemical industry for dehydration operations.

[Improvement] Single-row cross-column rotary support or single-row four-point contact spherical rotary support are selected. The collector has good insulation and the exposed rotary parts have portable protective cover.

Advantages

- Adding degassing tank to eliminate solid particles adhering to bubbles.

- Buffer box is added on the central support to prevent overflow caused by the overflow of pulp.

- The center support is rotary, compact structure, good sealing, steel ball and arc raceway contact at four points, can withstand axial force, radial force and overturning moment at the same time, easier maintenance, convenient refueling, and prolonged practical life.

- The feeding barrel is moved down to make the feeding pulp fall evenly and smoothly, thus effectively preventing the overturning phenomenon caused by the rock pressure.

- Adding flocculant adding the device to the feeding pipe can increase the processing capacity by 3-6 times.

Structure

Peripheral driving thickener is mainly composed of rake, trough frame, central bracket, collector, transmission device, etc. Its transmission device is to transfer the motion and power of motor to the truss hanging on the target, make the truss rotate uniformly around the center in the pool, and target the concentrate product to the outlet of the bottom center of the pool, in which the slurry in the pool is deposited on the gravity sedimentation pool. Sludge at the bottom is continuously scraped and collected by a rake dredger and discharged from the central outlet at the bottom of the pond. The upper part is the overflow water, which overflows from all sides of the pond to complete the solid-liquid separation.

Technical Parameter

Model | Diameter mm | Depth mm | Capacity t/d | Area m2 | Motor | Power kw | Weight kg |

DLNT-15 | 15000 | 3500 | 88~390 | 177 | Y132M2-6 | 5.5 | 11702 |

DLNT-18 | 18000 | 3700 | 127~560 | 255 | Y132M2-6 | 5.5 | 12120 |

DLNT-24 | 24000 | 3400 | 226~1000 | 452 | Y160M-6 | 7.5 | 28270 |

DLNT-30 | 30000 | 3940 | 353~1570 | 707 | Y160M-6 | 7.5 | 31000 |

DLNT-45 | 45000 | 5025 | 790~2400 | 1590 | Y160L-6 | 11 | 58640 |

DLNT-53 | 53000 | 5070 | 1000~3400 | 1964 | Y160L-6 | 11 | 69410 |

DLNG-15 | 15000 | 3612 | 88~390 | 177 | Y132M2-6 | 5.5 | 11702 |

DLNG-18 | 18000 | 3500 | 127~560 | 255 | Y132M2-6 | 5.5 | 9718 |

DLNG-24 | 24000 | 3400 | 226~1000 | 452 | Y160M-6 | 7.5 | 24000 |

DLNG-30 | 30000 | 3940 | 353~1570 | 707 | Y160M-6 | 7.5 | 31000 |

DLNG-45 | 45000 | 5060 | 790~2400 | 1590 | Y160L-6 | 11 | 50640 |

DLNG-53 | 53000 | 5070 | 1000~3400 | 2202 | Y160L-6 | 11 | 60910 |