Magnetic Separator

Blackstone International Company Limited- Type:Magnetic Separator

- Certification:ISO9001:2000

- Energy Saving:Energy Saving

- Condition:New

Base Info

- Model NO.:Magnetic Separator

Description

Basic Info.

Model NO. Magnetic SeparatorProduct Description

Magnetic Separator

[Introduction] Used for separating fine magnetic minerals or removing mixed magnetic minerals from non-magnetic minerals.

[Capability] 24t/h-240t/h

[Improvement] High performance, high coercivity, high remanence, and Nd-Fe-B materials are selected as magnetic materials, and wear-resistant rubber can be lined on the surface of the cylinder.

Application

The magnetic separating cylinder of permanent magnet barrel magnetic separator can be equipped with three grooves, i.e. semi-countercurrent groove, downstream groove and countercurrent groove, to meet different separation requirements. Semi-counter-current trough permanent magnet barrel magnetic separator is suitable for roughing and separating ores with a particle size of 0.5-0 mm, especially for minerals with a particle size of 0.15-0 mm. Permanent magnet barrel magnetic separator with a downstream trough is suitable for roughing and separating ores with a particle size of 6-0 mm. Countercurrent trough permanent magnet barrel magnetic separator is suitable for roughing and sweeping of ores with a particle size of 0.6-0 mm, as well as heavy medium recovery in coal preparation industry.

Advantages

- Nd-Fe-B magnets with high magnetic energy product and high coercivity are used in all magnetic systems. They have high magnetic field intensity and great depth of action.

- High-efficiency separation of magnetic minerals and non-weak magnetic minerals can be achieved by increasing the length of separation band and the number of magnetic flip times in the large envelope angle magnetic system with gradient field strength and smooth transition.

- The magnet system is coated with non-magnetic stainless steel to ensure that the magnet does not fall off.

- According to different uses and separation conditions, each series of magnetic separators has different magnetic system design and groove structure.

- The structure of the groove body is semi-counter-current type. It can also be made into parallel-flow type groove body according to sorting conditions and user requirements.

- The service life of the cylinder is significantly improved by using non-magnetic stainless steel and coated with wear-resistant rubber.

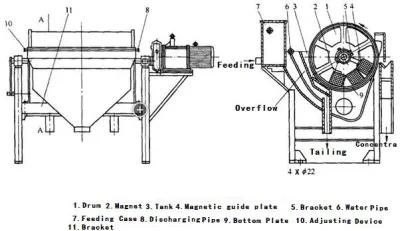

Structure

Permanent magnet barrel magnetic separator can be divided into three types according to the different structure of its box bottom, i.e. the downstream type, the countercurrent type and the semi-countercurrent type.

Parallel flow type: Pulp feeding direction is the same as cylinder steering, concentrate is discharged on the other side, tailings are discharged directly at the bottom. It is generally applied to 6-0 mm strong magnetic minerals for coarse and fine separation, with low recovery rate and high grade (due to strong magnetic overturning), but it is not suitable to treat fine particles (due to the lower relative velocity of movement between cylinder and pulp, and poor cleaning effect).

Countercurrent type: Pulp feeding direction is opposite to cylinder direction, concentrate is discharged on one side of feeding, tailings are discharged on the other side. Generally used in 0.6-0 mm strong magnetic ore roughing and sweeping, the recovery rate is high (because the tailings discharge point is far away from the ore feeding mouth, the separation is adequate), but the grade is low (because of the poor magnetic rollover effect).

Semi-counter-current permanent magnet drum: the direction of pulp feeding is the same as that of drum turning half. On the contrary, it is different from the parallel-flow type in that the pulp rotates in a circle in the trough. Because the pulp is washed loose by the washed water, it can prevent inclusions, and the direction of the pulp movement is consistent with the direction of magnetic force, which is conducive to recovery. Because the 0.5-0 mm strong magnetic ore is coarse, fine, high recovery rate and grade, the pulp surface is stable, so the separation is stable, so it is widely used.

Technical Parameter

Model | CTB1018 | CTB1024 | CTB1030 | CTB1218 | CTB1224 | CTB1230 |

Drum Diameter(mm) | 1000 | 1000 | 1000 | 1200 | 1200 | 1200 |

Drum Length(mm) | 1800 | 2400 | 3000 | 1800 | 2400 | 3000 |

Magnetic Strength(mT) | 350~550 | 350~550 | 350~550 | 350~550 | 350~550 | 350~550 |

Drum Revolution(r/min) | 23 | 23 | 23 | 20 | 20 | 20 |

Capacity(t/h) | 42~65 | 53~86 | 82~124 | 58~97 | 71~120 | 103~158 |

Feeding Size(mm) | 0~10 | 0~10 | 0~10 | 0~10 | 0~10 | 0~10 |

pulp density(%) | 20~50 | 20~50 | 20~50 | 20~50 | 20~50 | 20~50 |

Motor Power(kw) | 5.5 | 7.5 | 7.5 | 7.5 | 11 | 11 |

Weight(t) | 5.2 | 6.4 | 7.1 | 6.7 | 7.2 | 8.9 |

- Pre:Xcf/Kyf Type Flotation Cell

- Next:Jigger