Sf Type Flotation Cell

Blackstone International Company Limited- Type:Sf Type Flotation Cell

- Certification:ISO9001:2000

- Energy Saving:Energy Saving

- Condition:New

Base Info

- Model NO.:SF Type Flotation Cell

Description

Basic Info.

Model NO. SF Type Flotation CellProduct Description

SF Type Flotation Cell

[Introduction] Mine flotation machine with self-suction slurry and self-suction gas.

[Capability] 0.24-12 m3/min

[Application] It is widely used in Beneficiation of non-ferrous metals, ferrous metals and non-metallic minerals, and is suitable for roughing and sweeping operations in large and medium flotation plants.

[Improvement] the impeller of both sides of the flotation machine has a backward tilting blade, which can realize double circulation of slurry in the tank, and the forward inclined tank has small dead angle and fast foam movement.

Advantages

- Large inspiratory capacity and low energy consumption.

- there is self-suction air, self-absorption slurry capacity, horizontal configuration, no need for foam pump.

- The speed around the impeller circle is low, the service life of wearable parts is long, the gap between the impeller and the cover plate is large, and the increase of the gap between the impeller and the cover plate due to wear has little effect on the inspiration.

- The slurry in the tank is circulated up and down in a fixed way, which is beneficial to the suspension of coarse-grained minerals.

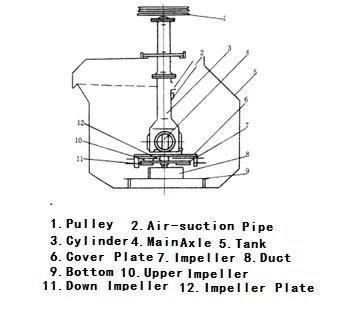

Structure

The motor drives the spindle through the V-belt to rotate the impeller. The impeller has backward inclined double-sided blades, which can realize the double circulation of pulp in the tank. When the impeller rotates, the pulp in the upper and lower impeller chambers produces centrifugal force under the action of the upper and lower blades (i.e. the main and auxiliary blades) and is thrown around, thus forming a negative pressure zone in the upper and lower impeller chambers.

At the same time, the pulp on the top of the cover plate is absorbed into the upper impeller chamber through the circulating holes in the cover plate, thus forming the upper circulation of the pulp. The slurry discharged from the lower impeller chamber is larger than the three-phase mixture discharged from the upper impeller chamber, so the centrifugal force increases and the velocity decreases slowly. The three-phase mixture discharged from the upper impeller chamber generates additional impetus, which increases the centrifugal force, thus improving the vacuum in the upper impeller chamber and playing an auxiliary role in inspiration.

When the lower blade throws the pulp around, the lower pulp is supplemented to the center, thus forming the downward circulation of the pulp. The air is sucked into the upper impeller chamber through the suction pipe and the central cylinder, and mixed with the sucked slurry to form a large number of small bubbles. After steady flow through the cover plate, the air is evenly dispersed in the tank, forming mineralized bubbles. The bubbles are blown up to the foam layer and scraped out by the scraper.

Technical Parameter

Model | Volume m3 | Capacity m3/min | Impeller Diameter mm | Impeller Revolution rpm | Agitation Motor Power kw | Scraping Motor Power kw |

SF-0.37 | 0.37 | 0.2~0.4 | 300 | 352~442 | 1.5 | 0.55 |

SF-0.7 | 0.7 | 0.3~1.0 | 350 | 336~384 | 3 | 1.1 |

SF-1.2 | 1.2 | 0.6~1.6 | 450 | 312 | 5.5 | 1.1 |

SF-2 | 2 | 1.5 ~3 | 550 | 280 | 11 | 1.5 |

SF-2.8 | 2.8 | 1.5~3.5 | 550 | 280 | 11 | 1.5 |

SF-4 | 4 | 2.0 ~4 | 650 | 235 | 15 | 1.5 |

SF-6 | 6 | 3~6 | 760 | 191 | 30 | 2.2 |

SF-8 | 8 | 4.0 ~8 | 760 | 191 | 30 | 2.2 |

SF-16 | 16 | 5.0 ~16 | 850 | 169~193 | 45 | 1.5 |

SF-20 | 20 | 10 ~12 | 850 | 169~193 | 45 | 1.5 |