Conveyor Idler Set/Conveyor Roller/Rubber Coated Roller

Shandong Mingyang Conveyor Equipment Co., Ltd.- Type:Gravity Conveyor

- Structure:Roller Conveyor

- Material:Rubber

- Material Feature:Fire Resistant

- Certification:ISO9001:2008, ISO9001:2000

- Energy Saving:Energy Saving

Base Info

- Model NO.:MYC

- Warranty:2 Years

- Color:Multi Color

- Customized:Customized

- Condition:New

- After-sales Service:1 Year Warranty Under Normal Use Condition

- Transport Package:Packed in Seaworthy Carton for Export

- Trademark:MYC

- Origin:China

- HS Code:84313900

- Production Capacity:5000

Description

Basic Info.

Model NO. MYC Warranty 2 Years Color Multi Color Customized Customized Condition New After-sales Service 1 Year Warranty Under Normal Use Condition Transport Package Packed in Seaworthy Carton for Export Trademark MYC Origin China HS Code 84313900 Production Capacity 5000Product Description

The rubber coating of idler is to process the idler rubber rollers of different materials and apply rubber or other materials evenly on the surface of the roller through secondary manufacturing and processing, so as to achieve different effects and application fields.

The rubber coating of idler is to process the idler rubber rollers of different materials and apply rubber or other materials evenly on the surface of the roller through secondary manufacturing and processing, so as to achieve different effects and application fields.It can be divided into papermaking cots, printing and dyeing cots, printing cots, rice husking cots, metallurgical cots and oil printing cots according to their uses;

According to the surface shape, it can be divided into flat roller and pattern rubber roller;

According to the material, it can be divided into butyl cots, nitrile cots, polyurethane cots and silicone rubber cots.

It is generally composed of outer rubber layer, hard rubber layer, metal core, roll neck and vent hole.

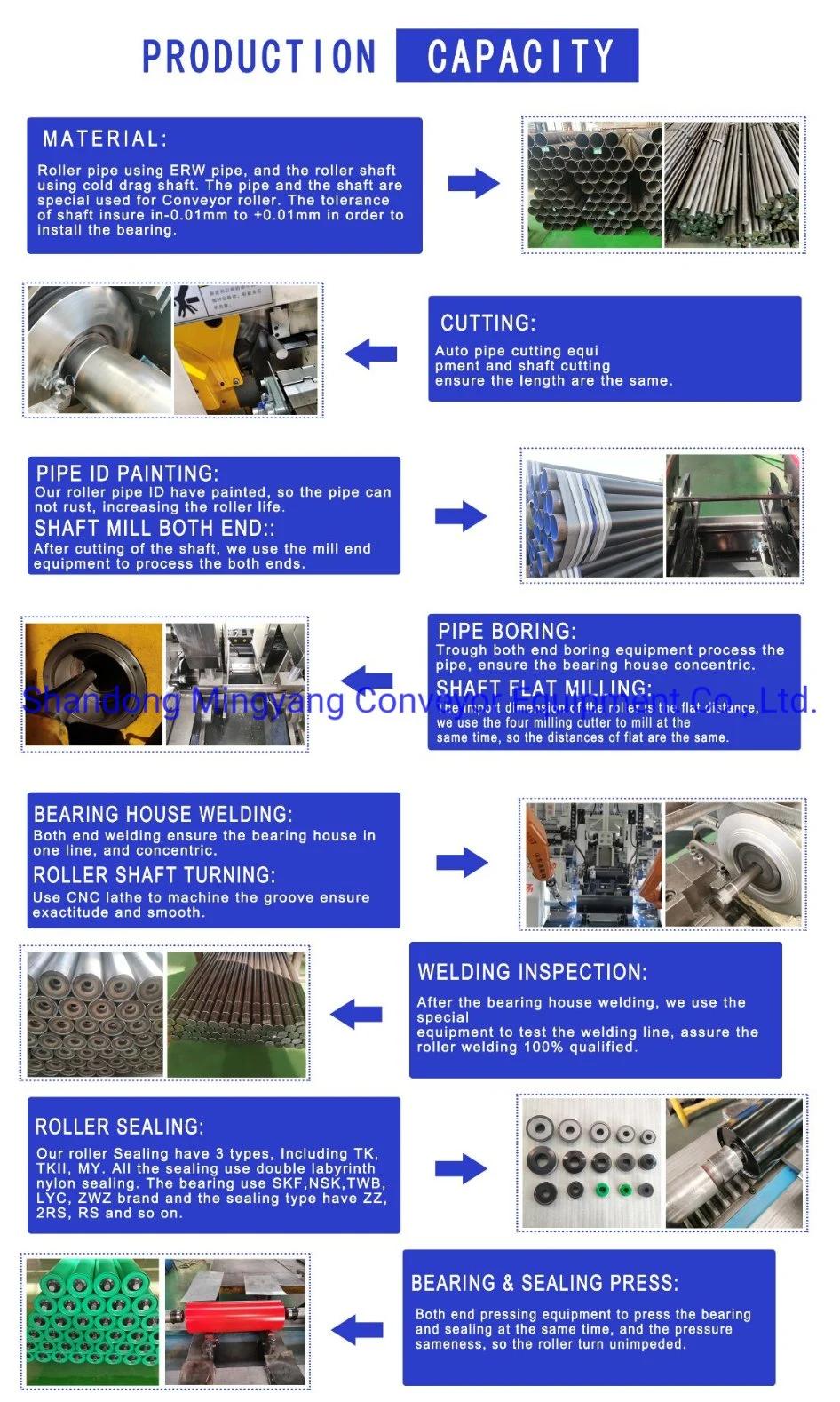

Its processing includes roller core sand blasting, bonding treatment, gluing molding, cloth wrapping, wire winding, vulcanization of vulcanization tank and surface processing.

Cots are mainly used in papermaking, printing and dyeing, printing, grain processing, metallurgy, plastic processing and so on.

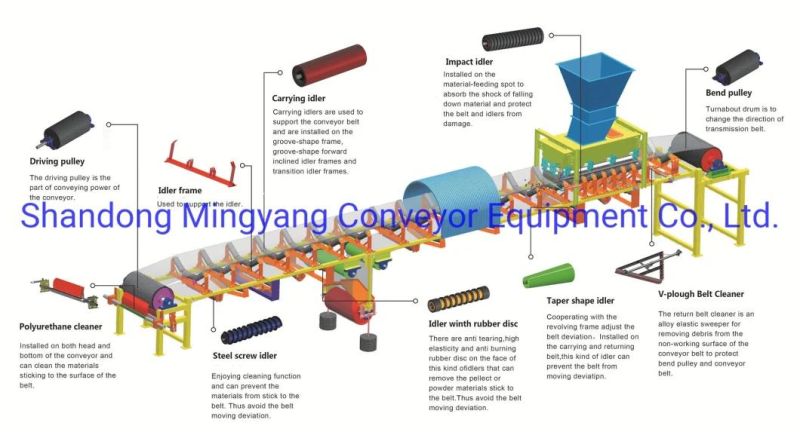

Roller is an important part of belt conveyor. It has many kinds and large quantity, and can support the weight of conveyor belt and materials. It accounts for 35% of the total cost of a belt conveyor and produces more than 70% resistance, so the quality of idler is particularly important. They are made of steel and plastic.

The function of roller is to support the conveyor belt and material weight. The idler must operate flexibly and reliably. Reducing the friction between conveyor belt and idler plays a key role in the service life of conveyor belt, which accounts for more than 25% of the total cost of conveyor. Although idler is a small part in belt conveyor and its structure is not complex, it is not easy to manufacture high-quality idler.