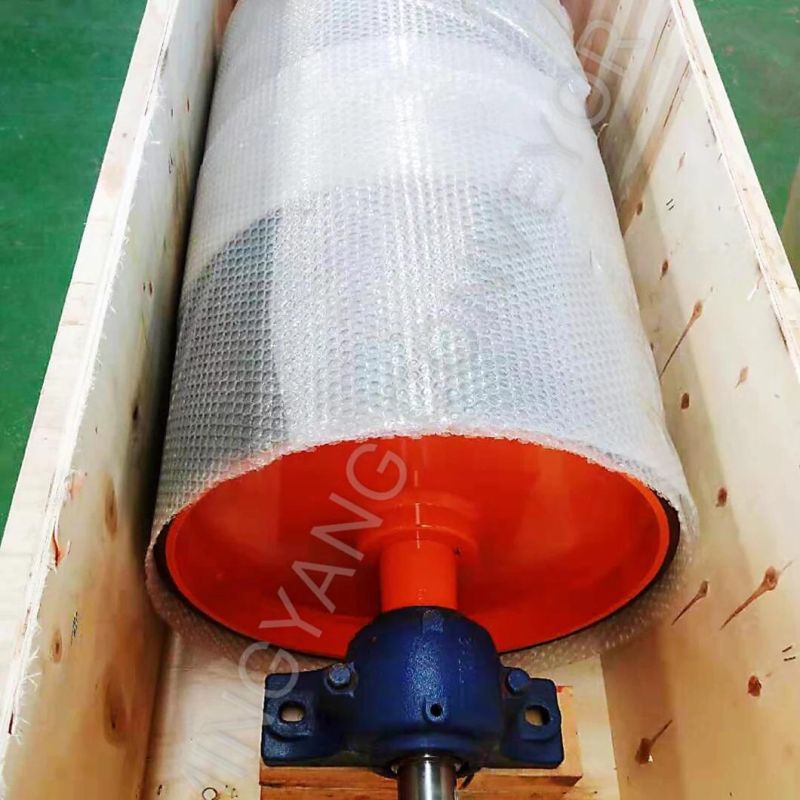

Non Drive - Ø 400 1500face 1927.5shaft Ø 90shaft Pulley

Shandong Mingyang Conveyor Equipment Co., Ltd.- Type:Gravity Conveyor

- Structure:Roller Conveyor

- Material:Rubber

- Material Feature:Fire Resistant

- Certification:ISO9001:2008, ISO9001:2000

- Energy Saving:Energy Saving

Base Info

- Model NO.:MYC

- Warranty:2 Years

- Color:Multi Color

- Customized:Customized

- Condition:New

- After-sales Service:1 Year Warranty Under Normal Use Condition

- Transport Package:Packed in Seaworthy Carton for Export

- Trademark:MYC

- Origin:China

- HS Code:84313900

- Production Capacity:5000

Description

Basic Info.

Model NO. MYC Warranty 2 Years Color Multi Color Customized Customized Condition New After-sales Service 1 Year Warranty Under Normal Use Condition Transport Package Packed in Seaworthy Carton for Export Trademark MYC Origin China HS Code 84313900 Production Capacity 5000Product Description

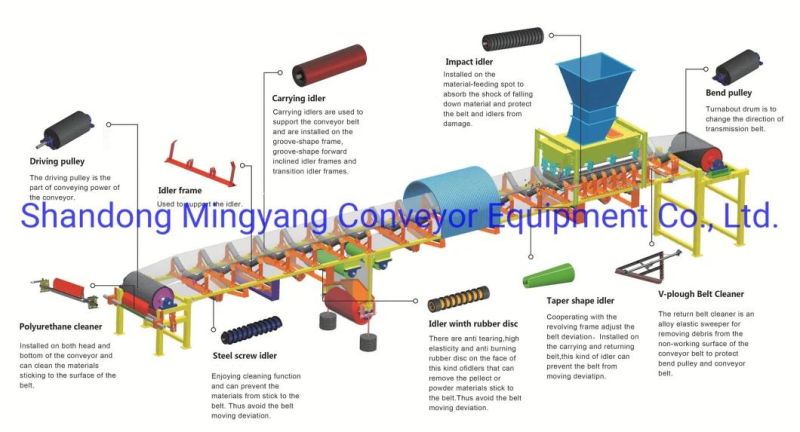

Pulley is indispensable for belt conveyor and an important component of its assembly line system. The most commonly used materials of rubber coated Pulley are: carbon steel galvanized, carbon steel chrome plated, carbon steel rubber coated, aluminum alloy, stainless steel, ABS, etc.

Pulley is indispensable for belt conveyor and an important component of its assembly line system. The most commonly used materials of rubber coated Pulley are: carbon steel galvanized, carbon steel chrome plated, carbon steel rubber coated, aluminum alloy, stainless steel, ABS, etc.Pulley, divided into driven and driven rollers, is used in various transmission and conveying systems such as conveying equipment and packaging machinery. Most of them are made of stainless steel, steel castings and solid forged alloy steel core.

The production of roller is mainly composed of roller body initial turning, initial static balance calibration, shaft head interference assembly and welding, fine turning and fine dynamic balance calibration. If the behavior tolerance such as roundness, cylindricity and straightness is less than 0.2mm, it needs to be ground by cylindrical grinder or roll grinder after finishing. If surface hardness is required, heat treatment process shall be added. After roller forming, for the needs of rust prevention, corrosion resistance, wear resistance and support, surface treatment or coating is also required, such as painting, galvanizing, Teflon spraying, rubber coating, chromium plating, ceramic spraying and oxidation.

Pulley selection

1. Selection of roller length: for goods with different widths, rollers with suitable width shall be selected. Generally, "conveyor + 50mm" shall be adopted.

2. Selection of Pulley wall thickness and shaft diameter: evenly distribute the weight of the conveyor to the contact Pulley, calculate the required load of each Pulley, and then determine the Pulley wall thickness and shaft diameter.

3. Pulley material and surface treatment: determine the material and surface treatment (carbon steel galvanizing, stainless steel, blackening or glue coating) adopted by the Pulley according to the different conveying environment.

4. Select the installation mode of the Pulley: according to the specific requirements of the overall conveyor, select the installation mode of the Pulley: spring press in type, internal tooth shaft type, full flat tenon type, through shaft pin hole type, etc. For the conical Pulley of the bending machine, the rolling surface width and taper depend on the cargo size and turning radius.