PF Series Impact Crusher Spare Parts for Blow Bar

Luoyang Zhongtai Industries Co., Ltd.- After-sales Service:Twenty Four Hour Online

- Warranty:a Year

- Material:High Chrome Crusher Hammer

- Molding Process:Water-Glass Sand Casting or Lost Form Casting

- Melting Facility:Medium Frequency Electric Furnace

- Heat Treatment:Anneal, Quenching, Tempering

Base Info

- Model NO.:blow bar

- Testing:Hardness, Flaw Detector Test

- Certificate:ISO9001~2008 Passed; Bureau Veritas

- Quality Guarantee:One Year Against Manufacturing Defeat

- Transport Package:Simple Packaging

- Trademark:LYZT

- Origin:Luoyang, Henan

- Production Capacity:3000PCS,Year

Description

PF Series Impact crusher spare parts for blow bar

ZTIC is the leader in offering wear solutions to crusher operators in China. We provide wear parts with designs and alloys specifically developed for each application and specific location within each crusher.Our crusher parts are made of manganese steel - the toughest and most wear-resistant steel available. In addition to the crusher components listed above, we also make cast components for the crusher itself such as the pitman arm, side plates, cheek plates, etc.

GENERAL DESCRIPTION

Wear components for crushing processes are subjected to severe impact and high abrasion, requiring components made from impact resistant and abrasion resistant alloys.

High Chrome Blow BarMaterial Cr15Mn2,Cr20Mn2,Cr26Mn2 Control Spectrometer chemical analysis and control while producing Molding Process Water-glass sand casting or lost form casting Melting facility Medium frequency electric furnace Heat Treatment Anneal, quenching, tempering Quality Guarantee One year against manufacturing defeat Testing Hardness, flaw detector test Certificate ISO9001~2008 Passed; BUREAU VERITAS Suit Filed Cement plants, gravel firms, coal gangue treatment plants and block plants.

Specifications:

MaterialC Cr Mn Si S p Cr15 2.8~3.2 13~15 ≤2 ≤1.2 ≤0.06 ≤0.06 Cr20 2.8~3.2 18~22 ≤2 ≤1.2 ≤0.06 ≤0.06 Cr26 2.8~3.2 24~26 ≤2 ≤1.2 ≤0.06 ≤0.06

High Manganese Blow Bar

Blow bar is the main crusher spare parts of impact crushers. After water toughening treatment high manganese blow bar has very high impact toughness, which has the incomparable advantage over other wear-resistant materials. Our company produces the series of high manganese blow bar are: ZG120Mn13Cr2, ZG120Mn18Cr2, ZG120Mn13Cr2 tungsten titanium alloy blow bar, which mainly used in high hardness materials and hard broken condition. Super-high-manganese steel hammer after water toughening treatment, then using the aging tretment process,make the austenitic matrix dispersion distribution in the abrasive particles,thus greatly improve the wear resistance of high manganese blow bar.

The invention of high manganese steel material crusher spare parts has a history of more than one hundred years. Becauseof its excellent work hardening properties(maxium work hardening capacity is over 600 HBW), and make it has high wear resistance. The harder external shocks high manganese material crusher spare parts is attached,the higher wear resistance high manganese crusher spare parts. With the gaddul wear and tear of surface hardinglayer,the new will continuously form.So our high manganese crusher spare parts series blow bar issuitable for the complex structure, the big impact, high toughness condition.High manganese blow bar: while casting, we not only add molybdenum,vanadium,titanium, nickel, boron and other rare alloy elements. Meantime, wespecially adopt variety of alloy modifier to strengthen the matrix. Those blowbars use refining, vacuum casting, directional solid and etc technical's toincrease the grain refinement and make the hammers performance achieve the bestperformance. Our crusher spare parts have successfully replaced the counter-attackinglarge Blow Bars of Germany Krupp, Blow Bars of Germany Aubema, counter-attackingBlow Bars of Germany Hazemag and make them nationalization.

Details:

· Emply the external refining technology effectively reduced the impact crushers, impurity and oxygen and hydrogen harm, greatly enhanced the abrasion resistance and impact toughness of the steel.

· Using proprietary metamorphic agent for impact crushers, fine grains, improves carbide configuration and distribution, and to improves the abrasion resistance and tenacity.

· Optimizing heat treatment process, make the product of uniform hardness especially, impact abrasion resistance becoming stronger.

High manganese blow barMaterial ZG120Mn13Cr2, ZG120Mn18Cr2, ZG120Mn13Cr2 tungsten titanium alloy Control Spectrometer chemical analysis and control while producing Molding Process Water-glass sand casting or lost form casting Melting facility Medium frequency electric furnace Heat Treatment Anneal, quenching, tempering Quality Guarantee One year against manufacturing defeat Testing Hardness, flaw detector test Certificate ISO9001:2008;BUREAU VERITAS OEM Accepted Suit Filed Cement, mining, quarry, power and metallurgy companies

Specifications:

Blow Bar Chemical ComponentMaterial c Mn Cr Si Mo Ni Cu Mn13Cr2 1.1~1.4 12~15 1.7~2.2 0.3~1.0 ---- ---- ---- Mn18Cr2 1.1~1.4 17~19 1.8~2.2 0.3~1.0 ----- ---- ----

Impact crusher spares

Blow Bars,Impact Plates,Liner Plates, Bearing Houses,Replacement Rotors, Bearings, Springs,Grinding Paths

CV series - CV215 | CV216 | CV217 | CV218 | CV228 | CV229

Impact Crusher wearparts:

ZTIC offers Long Life VSI Anvils and Shoes designed to put more metal in high abrasion areas for longer life between changeouts. Other parts which are available include Feed Tubes, Feed Disks, Table Liners, Outer Table Liners, Upper Tub Liners, Lower Tub Liners, and Pedestal Skirt Liners.We also make long-lasting wear parts for horizontal shaft impactors, including Standard and Heavy Duty Impeller Bars, Curtain Liners and Liner Plates.

Blow bar

hammer plate

liner plates

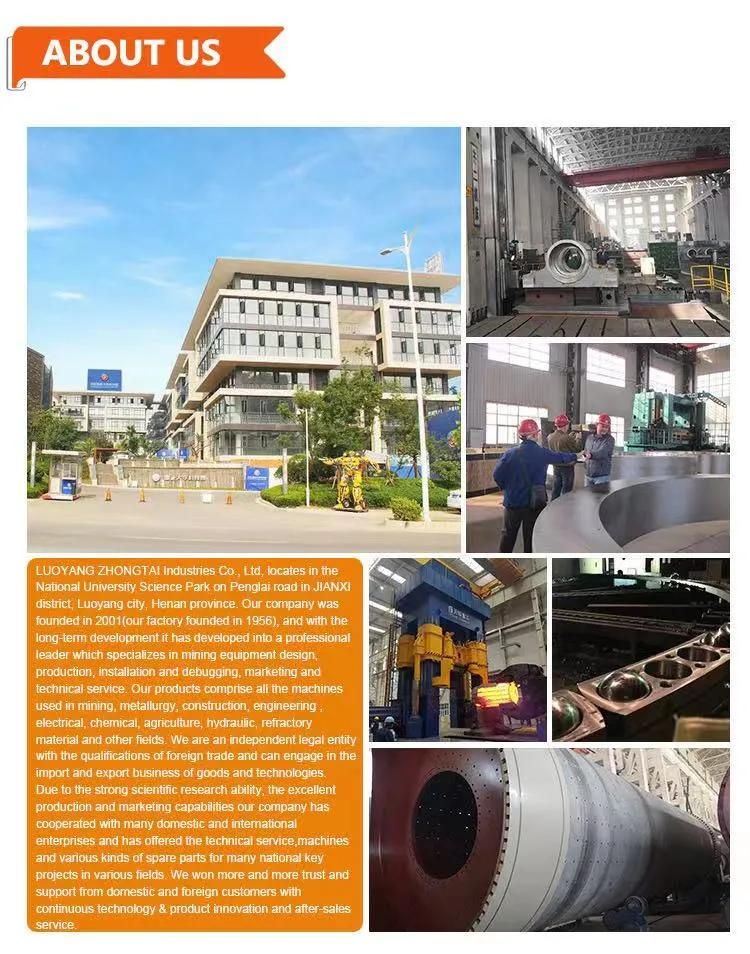

Company Information

FAQ

FAQ

After Sales Service

ZTIC Heavy Industries is your business partner in the After Market.

ZTIC able to provide:

1. ENGINEERED SPARES - DESIGN AND MANUFACTURING

2. LARGE VOLUME STEEL AND IRON CASTING FOUNDARIES

3. HUGE MACHINE SHOP CAPABILITIES

4. TRAINING PROGRAMMES

5. PREVENTATIVE MAINTENANCE PROGRAMS

6. PREVETATIVE MAINTENANCE SERVICES

7. COMPREHENSIVE MAINTENANCE PROGRAMS

ZTIC's Field Service Engineers are trained specifically in the CITIC brand group products but are capable of undertaking the servicing of other OEM brands.

Our technicians are equipped with the most advanced technological diagnostic equipment available to trouble shoot your equipment to optimise performance and minimise down time.

ZTIC also has an extensive capability in supplying all you consumable and electrical/ mechanical spare part needs.