Vertical Mill &Roller Mill for Cement Clinker Grinding Plant

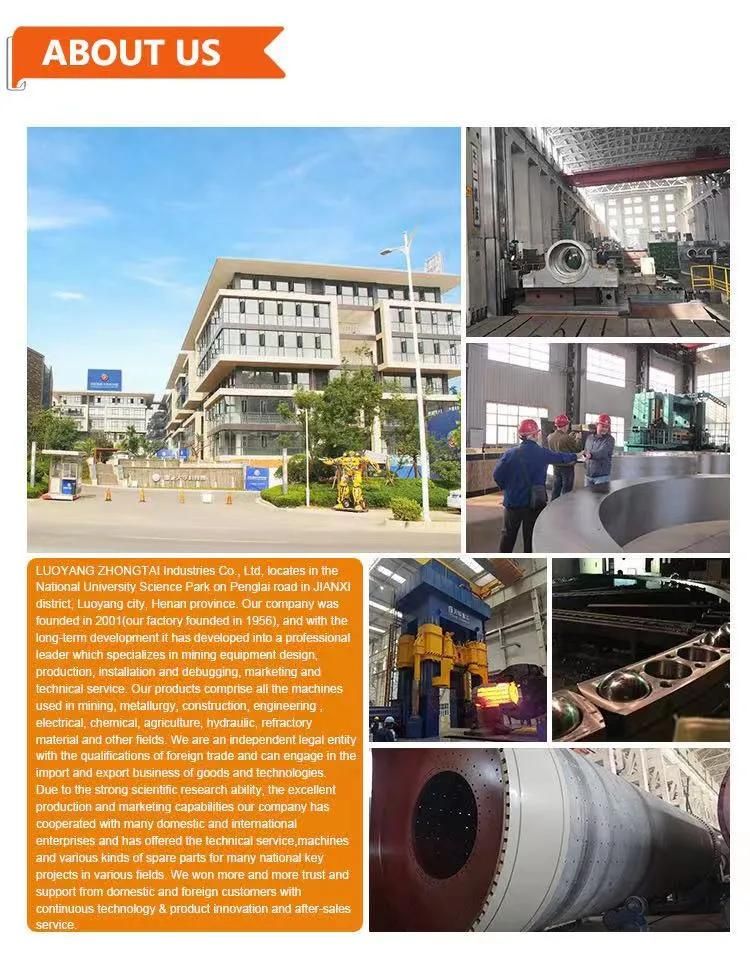

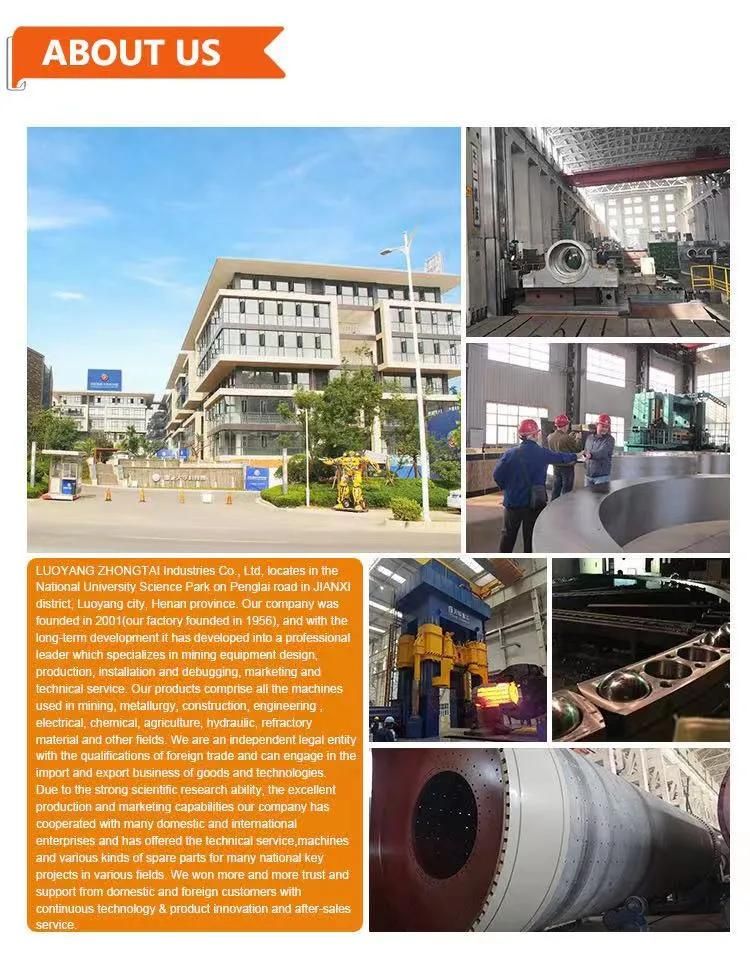

Luoyang Zhongtai Industries Co., Ltd.- Type:Slag Vertical Mill

- Motor Type:AC Motor

- Motor Power:500-5000 Kw

- Rotationl Speed:Slag Vertical Mill

- Application:Construction

- Materials:Slag Vertical Mill

Base Info

- Model NO.:Vertical Mill

- Condition:New

- Warranty:a Year

- After-sales Service:Twenty Four Hour Online

- Application Industry:Slag Vertical Mill

- Output:30-1000

- Power Consumption of System:25~30 Kwh,T

- Certification:ISO,Ce

- Transport Package:Simple Packaging

- Trademark:LYZT

- Origin:Luoyang, Henan

- Production Capacity:500PCS,Year

Description

Overview

Product DescriptionGrinding diameter Roll diameter Roller number Standard power capacity D(mm) D(mm) (n) P(kW) (t/h) LKMC12.20 1200 900 2 110 5 LKMC16.20 1600 1000 2 250 12 LKMC18.20 1800 1120 2 330 18 LKMC20.30 2000 1250 3 430 20 LKMC22.30 2200 1400 3 590 30 LKMC23.30 2300 1450 3 640 35 LKMC26.30 2600 1600 3 810 44 LKMC28.30 2800 1750 3 1000 55 LKMC30.30 3000 1900 3 1250 65 LKMC35.30 3500 1900 3 1400 70

Slag Vertical Mill

Our vertical slag mill is typically designed to deal with industrial waste residues generated by the blast-furnace ironmaking. Due to its high physical and chemical activity, and potential hydraulicity, the slag has been widely as admixture matters in the cement industry. And the slag can replace the cement in the concrete to improve the quality and durability of the concrete.

Here in ZTIC Co., Ltd, our vertical slag mill has features of high grinding efficiency, strong dry capacity, easy adjustment, low noises, low electricity consumption, simple process flow, little abrasion, and so on.

Slag Vertical Mill SpecificationsModel Grinding diameter Roll diameter Roller number power Scapacity (mm) (mm) (n) (kW) (t/h) LKMS33.31 3200 1700 3 1600 50 LKMS35.41 3500 1800 4 1800 60 LKMS40.41 4000 1900 4 2240 70 LKMS43.41 4300 2120 4 2800 90 LKMS46.41 4600 2240 4 3150 105 LKMS48.41 4800 2240 4 3550 125 LKMS50.41 5000 2360 4 3800 140 LKMS53.41 5300 2500 4 4200 160 LKMS56.61 5600 2500 6 5000 180

(1) Material medium friction (MFs)=0.9~1.0;

(2) Material moisture max 15%;

(3) Refined powder granularity 4200~4500 cm²/g;

(4) Refined powder moisture 0.5~1.0%;

(5) The concrete mill installed power and technology parameter will be adjusted appropritely basing on the actual material property and requirements of owner;

FAQ

FAQ

After Sales Service

Vertical Mill:

1. Cement Vertical Mill &Coal Vertical Mill&Raw Vertical Mill&Slag Vertical Mill

2 .Ztic Vertical Mill

Model

Slag Vertical Mill

Our vertical slag mill is typically designed to deal with industrial waste residues generated by the blast-furnace ironmaking. Due to its high physical and chemical activity, and potential hydraulicity, the slag has been widely as admixture matters in the cement industry. And the slag can replace the cement in the concrete to improve the quality and durability of the concrete.

Here in ZTIC Co., Ltd, our vertical slag mill has features of high grinding efficiency, strong dry capacity, easy adjustment, low noises, low electricity consumption, simple process flow, little abrasion, and so on.

Slag Vertical Mill Specifications

(1) Material medium friction (MFs)=0.9~1.0;

(2) Material moisture max 15%;

(3) Refined powder granularity 4200~4500 cm²/g;

(4) Refined powder moisture 0.5~1.0%;

(5) The concrete mill installed power and technology parameter will be adjusted appropritely basing on the actual material property and requirements of owner;

FAQ

FAQAfter Sales Service

ZTIC Heavy Industries is your business partner in the After Market.

ZTIC able to provide:

1. ENGINEERED SPARES - DESIGN AND MANUFACTURING

2. LARGE VOLUME STEEL AND IRON CASTING FOUNDARIES

3. HUGE MACHINE SHOP CAPABILITIES

4. TRAINING PROGRAMMES

5. PREVENTATIVE MAINTENANCE PROGRAMS

6. PREVETATIVE MAINTENANCE SERVICES

7. COMPREHENSIVE MAINTENANCE PROGRAMS