Gongyi Hengchang machinery Mobile Quartz Crusher Line

Gongyi Hengchang Metallurgical Building Material Equipments Plant- Type:Jaw Crusher

- Motor Type:AC Motor

- Motor Power:15kw

- Application:Construction

- Materials:Fine Sandstone

- Outlet Size:20-50mm

Base Info

- Model NO.:PE

- Inlet Size:210mm

- Condition:New

- Name:Mobile Quartz Crusher Line

- Keywords:Quartz Stone Production Line

- Installation:Engineer Guide

- After Sale Service:Maintenance

- Material:High Manganese Steel

- Max Feeding Size:210mm

- Certification:Ce,ISO9001,SGS,BV

- MOQ:1 Set

- Shaft Speed:300 R,Min

- Market:Africa

- Transport Package:Wooden Case, Standard Container

- Specification:2900 kg

- Trademark:Hengchang

- Origin:China

- HS Code:8474209000

- Production Capacity:100 Set,Day

Description

Basic Info.

Model NO. PE Inlet Size 210mm Condition New Name Mobile Quartz Crusher Line Keywords Quartz Stone Production Line Installation Engineer Guide After Sale Service Maintenance Material High Manganese Steel Max Feeding Size 210mm Certification Ce,ISO9001,SGS,BV MOQ 1 Set Shaft Speed 300 R/Min Market Africa Transport Package Wooden Case, Standard Container Specification 2900 kg Trademark Hengchang Origin China HS Code 8474209000 Production Capacity 100 Set/DayProduct Description

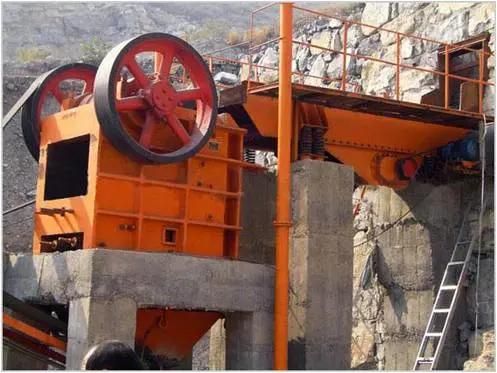

1.Product Description Of Gongyi hengchang machinary mobile Quartz Crusher LineFactory Outlet PE-250 x 400 Jaw Crusher In Stock is widely used in mining, smelting, building material, highway, railway, water conservancy and chemical indrustry, for the medium- grained broken of variety of ores and bulk materials.

Jaw crusher can break the bulk material into small uniformed particles; it is the corollary equipment of sand/stone making plant and ore beneficiation plant. it can also be used to produce road cornerstone and construction stone .

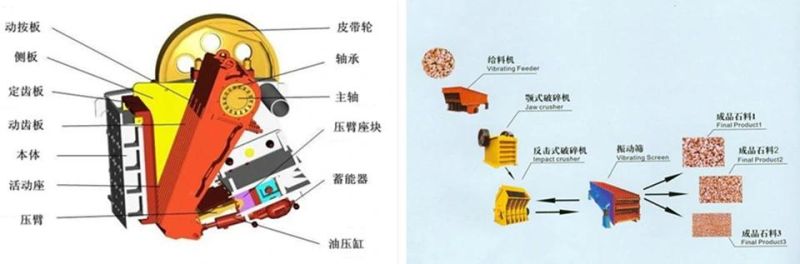

2.Working principle Of Gongyi hengchang machinary mobile Quartz Crusher Line

Primary jaw crusher is typical design of the square opening technic, and secondary jaw crusher is according to the rectangular opening design. Jaw Crusher reduces large size rocks or ore by placing the rock into compression.

A fixed jaw board, mounted in a "V" alignment is the stationary breaking surface, while the movable jaw exerts force on the rock by forcing it against the stationary plate. The space at the bottom of the "V" aligned jaw plates decide the crusher product size gap, or the size of the crushed product from the jaw crusher. The rock remains in the jaw until it is small enough to pass through the gap at the bottom of the jaws.

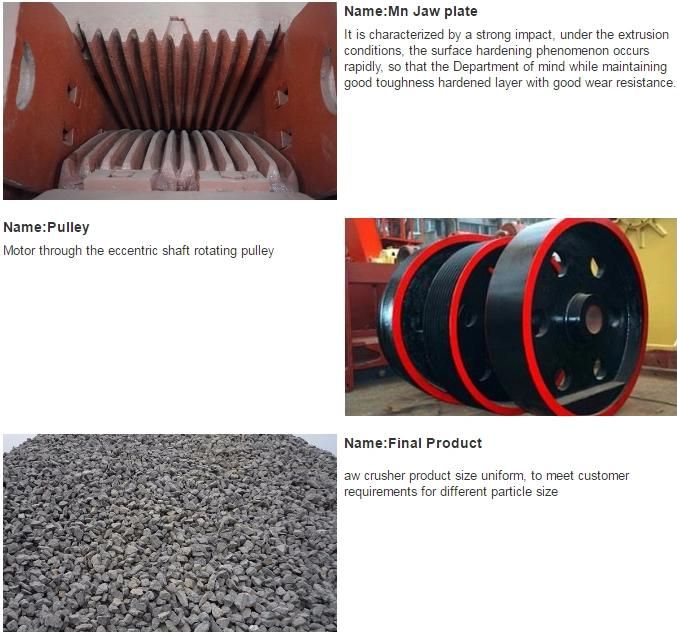

3.Main Features Of Gongyi hengchang machinary mobile Quartz Crusher Line

1-The deep crushing cavity increases the feeding capacity and output capacity;2-High ratio of crushing, homogeneous final product size;

3-Adjusting the discharge opening through gasket, more convenient, it can meet different customers' requirenment

4-Lubricate system is safe and reliable, easy to change the spare parts;

5-Simple structure, easy maintenance, consumption cost is lower;

6-Energy-saving, for one set saving about 15%-30%;

7-Little noise and dust.

4.Detailed Images Of Gongyi hengchang machinary mobile Quartz Crusher Line

5.Our Company

Gongyi Hengchang Metallurgy Building Material Equipments plant is a professional manufacturer specializing in the production of mineral beneficiation equipments, sand and stone crushing equipments, briquetting equipments, coal preparation equipments, drying and calcining equipments, cement plant equipments and compound fertilizer equipments. The products are widely used in mineral processing, metallurgy, building materials, chemicals, electricity, petroleum, coal, transportation, fertilizer , gas industry etc.

6.Technical parameter Of Gongyi hengchang machinary mobile Quartz Crusher Line

| Model | Max. Feeding Size(mm) | Discharge Size (mm) | Capacity (t/h) | Motor Power (kw) | Shaft Speed (rpm) | Weight (kg) |

| PE150*250 | 125 | 10-40 | 1-3 | 5.5 | 285 | 750 |

| PE200*300 | 165 | 15-50 | 2-8 | 7.5 | 265 | 1100 |

| PE250*400 | 210 | 20-60 | 5-20 | 15 | 300 | 2900 |

| PE400*600 | 340 | 40-90 | 25-64 | 30 | 280 | 6900 |

| PE500*750 | 425 | 50-100 | 34-68 | 55 | 275 | 10500 |

| PE600*900 | 480 | 65-160 | 56-192 | 75 | 250 | 17500 |

| PE750*1060 | 630 | 80-140 | 110-242 | 90 | 250 | 27000 |

| PE900*1200 | 750 | 100-200 | 158-256 | 110 | 250 | 50000 |

| PEX150*750 | 125 | 10-40 | 8-35 | 15 | 300 | 3300 |

| PEX250*1000 | 210 | 15-50 | 15-50 | 30 | 300 | 7100 |

| PE2500*1200 | 210 | 15-50 | 20-60 | 45 | 300 | 8700 |

| PE300*1300 | 250 | 20-90 | 20-90 | 75 | 300 | 11600 |