25 Year Experience Floatation Tank Beneficiation Plant

Gongyi Hengchang Metallurgical Building Material Equipments Plant- Type:Flotation Separator

- Voltage:380V

- Weight:<1T

- Material:Carbon Steel

- Material Feature:Heat Resistant

- Certification:ISO9001:2008

Base Info

- Model NO.:SF

- Energy Saving:Energy Saving

- Warranty:1 Year

- Color:Multi Color

- Customized:Customized

- Condition:New

- Name:25 Year Experience Floatation Tank Beneficiation P

- Keywords:Floatation Tank

- Installation:Engineer Guide

- Impeller Speed:240-500 R,Min

- Power:3-15kw

- Price:Negotiation

- Capacity:0.12-7 M3,Min

- MOQ:1 Set

- Brand:Hengchang

- Quality:High Quality

- Transport Package:Container

- Specification:SF

- Trademark:Hengchang

- Origin:China

- HS Code:8474100000

- Production Capacity:100 Set,Day

Description

ModelSF-0.15 SF-0.37 SF-1.2 SF-2.8 SF-4 SF-6 SF-8 SF-10 SF-16 SF-20 Tank Volume (m3) 0.15 0.37 1.2 2.8 4 6 8 10 16 20 Tank size

(mm) 0.5×

0.5

×0.6 0.7×

0.7

×0.75 1.1×

1.1

×1.1 1.7×

1.6

×1.15 1.85×

2.05

×1.2 2.2×

2.2

×1.3 2.2×

2.2

×1.4 2.2×2.9

×1.7 2.9×

3.8

×1.7 2.85×

3.8

×2 Capacity

(m3/min) 0.06-0.18 0.2-0.4 0.6-1.2 1-3 2-4 3-6 4-8 5-10 5-15 5-20 Suction

intensity

(m3/m2

/min) 0.5-1.0 0.8-1.0 0.8-1.0 1-1.2 1-1.2 0.9-1.0 0.9-1.0 0.9-1.0 0.9-1.0 0.9-1.0 Main

motor Model Y100

L-6 Y90

L-6 Y132

M2-6 Y180

L-8 Y200

L-8 Y250

M-8 Y250

M-8 Y250M-8 Y250

M-8 Y250

M-8 Power

(kw) 1.5 1.5 5.5 11 15 30 30 30 30 30x2 Speed

(r/min) 940 1400 960 730 730 730 730 730 730 730 Impe

ller Dia.

(mm) 200 296 450 550 650 700 760 760 760 760 Height

(mm) 57 80 104 124 131 186 186 186 186 186

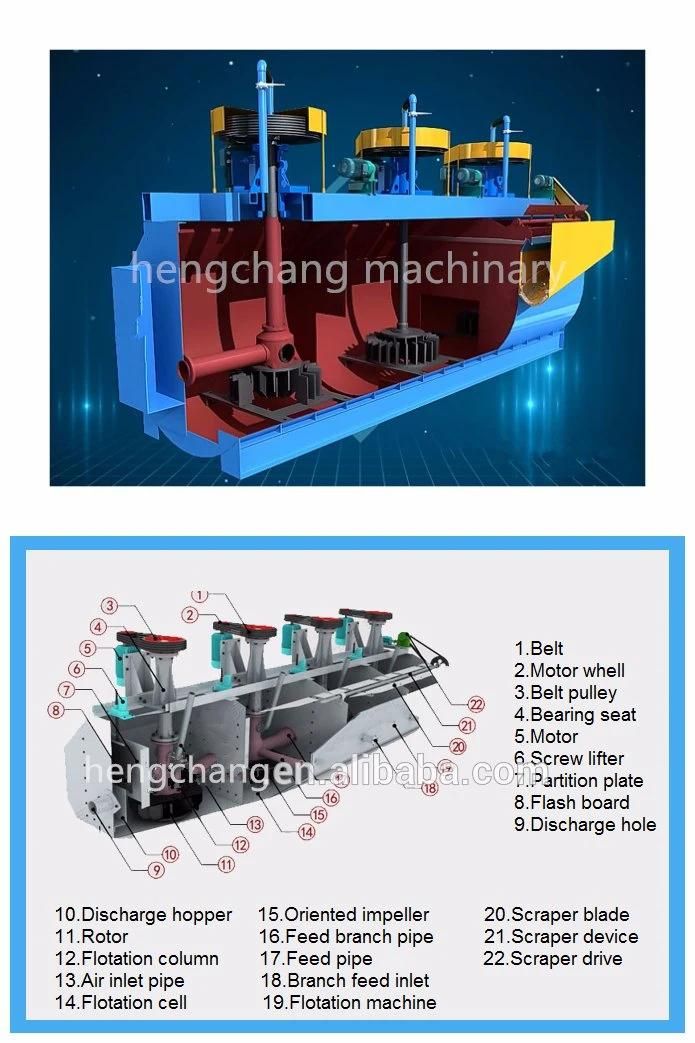

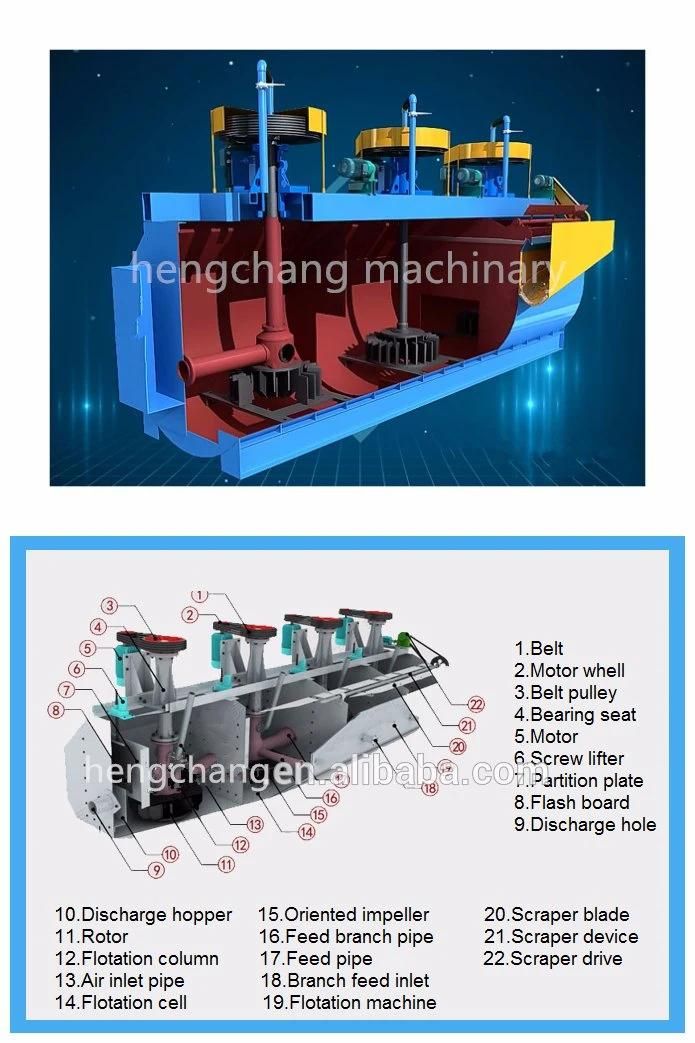

3.Working Principle Of 25 year experience Floatation Tank beneficiation plant

Flotation machine consists of flotation cells, impeller, belt pulley, inlet pipe, strobe, covering plate, standpipe, draw bar, etc.

When the floatation machine works, the motor drives the impeller to revolve, so the centrifugal effect and negative pressure are produced. On one hand, ample air is absorbed and mixed with mineral slurry, on the other hand, the mixed mineral slurry is mingled with additive, meanwhile, the foams are thinning, the mineral is bounded with foams, and floats up to the surface of mineral slurry and the mineralized foam is formed. The liquid surface can be adjusted with the height of adjustment flashboard, so that the useful foams are scraped with squeegee.

4.Main Features of 25 year experience Floatation Tank beneficiation plant

1. large air-absorption capacity

2. low energy consumption

3. less reagents consumption

4. easy to maintenance and can be designed according to the users.

5. Every cell owns three functions: air absorption, slurry absorption, and flotation separation, and the cells form a flotation separation loop by itself without any auxiliary equipment, and is allocated horizontally, which favors the change of flow.

6. The impeller has backward-inclined upper and lower vanes, which produce upper and lower circulation of mineral slurry respectively.

5.Detailed Images of 25 year experience Floatation Tank beneficiation plant

6.working and Delivery

7.Our Company

Gongyi Hengchang Metallurgy Building Material Equipments plant is a professional manufacturer specializing in the production of mineral beneficiation equipments, sand and stone crushing equipments, briquetting equipments, coal preparation equipments, drying and calcining equipments, cement plant equipments and compound fertilizer equipments. The products are widely used in mineral processing, metallurgy, building materials, chemicals, electricity, petroleum, coal, transportation, fertilizer , gas industry etc.

(mm)

0.5

×0.6

0.7

×0.75

1.1

×1.1

1.6

×1.15

2.05

×1.2

2.2

×1.3

2.2

×1.4

×1.7

3.8

×1.7

3.8

×2

(m3/min)

intensity

(m3/m2

/min)

motor

L-6

L-6

M2-6

L-8

L-8

M-8

M-8

M-8

M-8

(kw)

(r/min)

ller

(mm)

(mm)

3.Working Principle Of 25 year experience Floatation Tank beneficiation plant

Flotation machine consists of flotation cells, impeller, belt pulley, inlet pipe, strobe, covering plate, standpipe, draw bar, etc.

When the floatation machine works, the motor drives the impeller to revolve, so the centrifugal effect and negative pressure are produced. On one hand, ample air is absorbed and mixed with mineral slurry, on the other hand, the mixed mineral slurry is mingled with additive, meanwhile, the foams are thinning, the mineral is bounded with foams, and floats up to the surface of mineral slurry and the mineralized foam is formed. The liquid surface can be adjusted with the height of adjustment flashboard, so that the useful foams are scraped with squeegee.

4.Main Features of 25 year experience Floatation Tank beneficiation plant

1. large air-absorption capacity

2. low energy consumption

3. less reagents consumption

4. easy to maintenance and can be designed according to the users.

5. Every cell owns three functions: air absorption, slurry absorption, and flotation separation, and the cells form a flotation separation loop by itself without any auxiliary equipment, and is allocated horizontally, which favors the change of flow.

6. The impeller has backward-inclined upper and lower vanes, which produce upper and lower circulation of mineral slurry respectively.

5.Detailed Images of 25 year experience Floatation Tank beneficiation plant

6.working and Delivery

7.Our Company

Gongyi Hengchang Metallurgy Building Material Equipments plant is a professional manufacturer specializing in the production of mineral beneficiation equipments, sand and stone crushing equipments, briquetting equipments, coal preparation equipments, drying and calcining equipments, cement plant equipments and compound fertilizer equipments. The products are widely used in mineral processing, metallurgy, building materials, chemicals, electricity, petroleum, coal, transportation, fertilizer , gas industry etc.