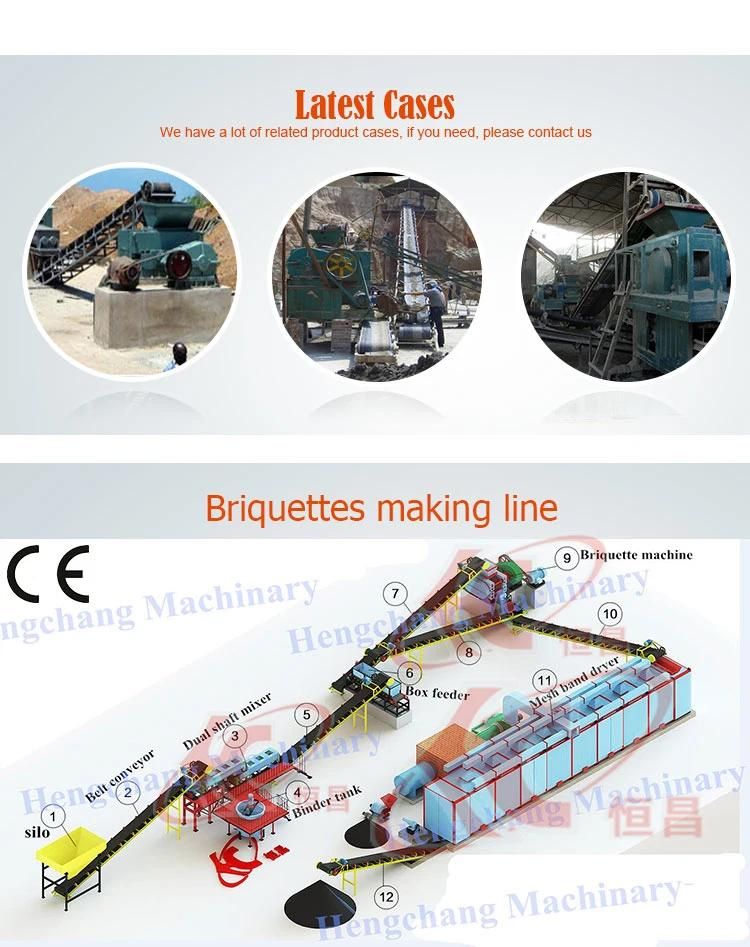

Hydraulic Pressure Swarf Metal Chip Briquette Machine

Gongyi Hengchang Metallurgical Building Material Equipments Plant- Pressing Mode:Force Feeding

- Product Shape:Square Shape

- Motor Type:AC Motor

- Condition:New

- Name:High Capacity Four Roller Twice Pressure Coal Ball

- Keywords:Coal Dust Press Machine

Base Info

- Model NO.:YQJ

- Installation:Engineer Guide

- Price:Negotiation

- MOQ:1 Set

- Certification:Ce,ISO9001,SGS,BV

- Application:Coal

- Market:Europe

- Roller Material:65 Mn

- Pressure Form:Constant Wedge Pressure

- Transport Package:Container

- Specification:QYQ

- Trademark:Hengchang

- Origin:China

- HS Code:8463900010

- Production Capacity:100 Set,Day

Description

Basic Info.

Model NO. YQJ Installation Engineer Guide Price Negotiation MOQ 1 Set Certification Ce,ISO9001,SGS,BV Application Coal Market Europe Roller Material 65 Mn Pressure Form Constant Wedge Pressure Transport Package Container Specification QYQ Trademark Hengchang Origin China HS Code 8463900010 Production Capacity 100 Set/DayProduct Description

General introduction of hydraulic briquette machine:A hydraulic high-pressure briquette machine is a machine using a hydraulic cylinder to generate a compressive force. It uses the hydraulic equivalent of a mechanical lever. It is widely used in metallurgical, chemical, coal, and refractory industries, suitable for wet powder briquetting, which is, adding an appropriate amount of water and other adhesives. This series machine uses a unique hydraulic system, improving the briquetting rate and strength. It is suitable for many materials such as light burning magnesium, iron oxide skin, manganese alloy, sludge, gypsum, carbon, silicon carbide, copper powder, iron powder, and various refractory materials.

Main features of briquette machine:

1. Good quality roller material with 65Mn/ 9Gr2Mo

2. Unique hydraulic system

3. Suitable for wet powder

4. Firm final product

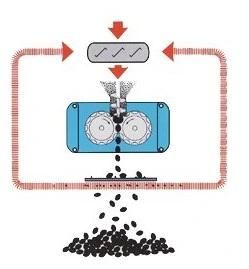

Working principle of briquette machine:

The hydraulic press depends on Pascal's principle: the pressure throughout a closed system is constant. One part of the system is a piston acting as a pump, with a modest mechanical force acting on a small cross-sectional area; the other part is a piston with a larger area which generates a correspondingly large mechanical force. Only small-diameter tubing (which more easily resists pressure) is needed if the pump is separated from the press cylinder. When the pressure on the press cylinder is released (the fluid returning to a reservoir), the force created in the press is reduced to a low value (which depends on the friction of the cylinder's seals.

| Model | Roller Dia. (mm) | Roller Width(mm) | Motor Power (kW) | Shaft Speed(r/min) | Reducer Model | Capacity (t/h) | Pressure Form | Roller Material |

| YYQ-476-1 | 476 | 210 | 22/1.5 | 15 | ZQ500 | 3-6 | Hydraulic Pressure | 65Mn |

| YYQ -476-2 | 476 | 260 | 30/1.5 | 15 | ZQ650 | 4-8 | Hydraulic Pressure | 9Cr2M0 |

| YYQ -500 | 500 | 300 | 30/1.5 | 15 | ZQ650 | 5-9 | Hydraulic Pressure | 65Mn/9Cr2M0 |

| YYQ -650 | 650 | 336 | 45/1.5 | 15 | ZQ750 | 8-15 | Hydraulic Pressure | 65Mn |

| YYQ -672 | 672 | 275 | 75/1.5 | 13 | ZQ1000 | 8-15 | Hydraulic Pressure | 9Cr2Mo |

| YYQ -750 | 750 | 400 | 55/1.5 | 13 | ZQ850 | 15-20 | Hydraulic Pressure | 65Mn/9Cr2Mo |

| YYQ -850 | 850 | 500 | 75/1.5 | 10 | ZQ850 | 20-30 | Hydraulic Pressure | 65Mn/9Cr2M0 |

| YYQ-1000 | 1000 | 650 | 110/1.5 | 10 | ZQ1000 | 30-50 | Hydraulic Pressure | 65Mn/9Cr2M0 |