Zimbabwe Peru Knelson Concentrator Alluvial Sand Separator

Gongyi Hengchang Metallurgical Building Material Equipments Plant- Type:Gravity Separator

- Voltage:380V

- Weight:>10T

- Material:Carbon Steel

- Material Feature:Heat Resistant

- Certification:ISO9001:2008, ISO9001:2000, CE

Base Info

- Model NO.:STLB

- Energy Saving:Energy Saving

- Warranty:1 Year

- Color:Multi Color

- Customized:Customized

- Condition:New

- Name:Zimbabwe Peru Knelson Concentrator Alluvial Sand S

- Keywords:Gold Extraction Equipment

- Feeding Size:Less Than 5mm

- Recovery Rate:90%

- Transport Package:Container

- Specification:STLB

- Trademark:hengchang

- Origin:Henan

- HS Code:8421192000

- Production Capacity:5000

Description

Basic Info.

Model NO. STLB Energy Saving Energy Saving Warranty 1 Year Color Multi Color Customized Customized Condition New Name Zimbabwe Peru Knelson Concentrator Alluvial Sand S Keywords Gold Extraction Equipment Feeding Size Less Than 5mm Recovery Rate 90% Transport Package Container Specification STLB Trademark hengchang Origin Henan HS Code 8421192000 Production Capacity 5000Product Description

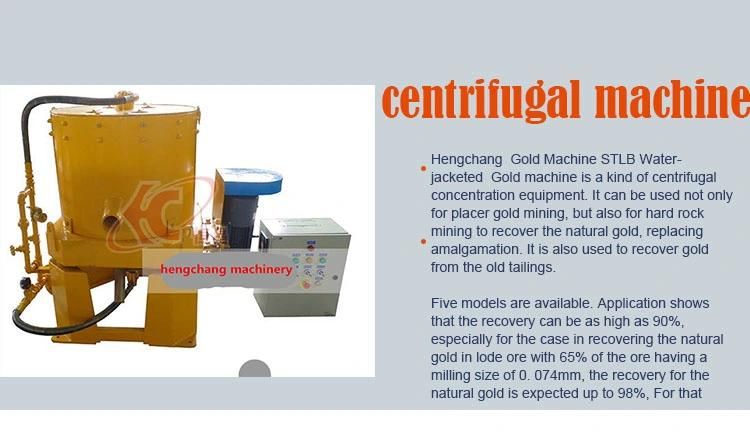

Zimbabwe Peru Knelson alluvial sand separator

Zimbabwe Peru Knelson alluvial sand separator

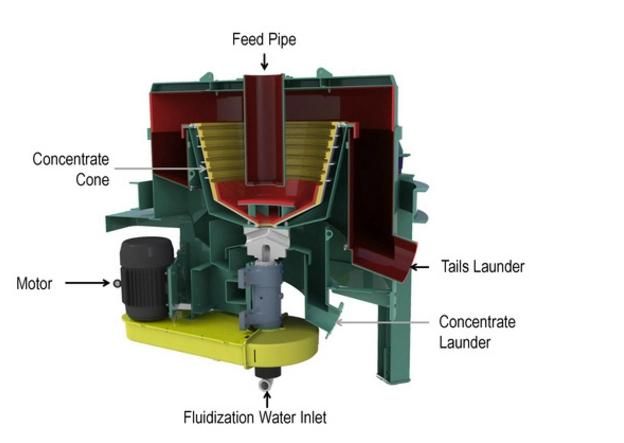

Centrifugal gold concentrator is a relatively new type of gravity concentration apparatus. The machines utilise the principles of a centrifuge to enhance the gravitational force experienced by feed particles to effect separation based on particle density. The key components of the unit are a cone shaped "concentrate" bowl, rotated at high speed by an electric motor and a pressurized water jacket encompassing the bowl. Feed material, typically from a ball mill discharge or cyclone underflow bleed, is fed as a slurry toward the centre of the bowl from above. The feed slurry contacts the base plate of the vessel and due to its rotation, is thrust outward. The outer extremities of the concentrate bowl house a series of ribs and between each pair of ribs is a groove. During operation the lighter material flows upward over the grooves and heavy mineral particles (usually of economic value) become trapped within them. Pressurized water is injected through a series of tangential water inlets along the perimeter of each groove to maintain a fluidized bed of particles in which heavy mineral particles can be efficiently concentrated.

Zimbabwe Peru Knelson alluvial sand separator

gold can be 98% or more, for rock gold, the recovery rate could reach 97% when the feeding size is below 7mm.

2) Easy to install: Only a small leveled place required. It's a full line machine, before starting it, we only need to connect the water pump and power.

3) Easy to adjust: There are only 2 factors that will affect the recovery result, they are water pressure and feeding size. By giving proper water pressure and feeding size, you could get the best recovery effect.

4) No pollution: This machine only consumes water and electric power, and exhaust tailing and water. Low noise, no chemical agent involved.

5)Easy to operate: After finishing the water pressure and feeding size adjust, clients only need to recover the concentrates every 2-4 hours. (Depending on the grade of the mine)

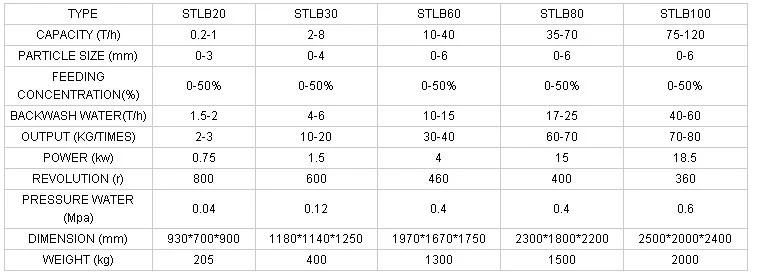

Technical Parameters of Zimbabwe Peru Knelson alluvial sand separator