Mn18, Mn22 Manganese Replacement for Stone Crusher Form Foundry

Shenzhen DENP Industrial Co., Ltd.- Certification:CE, ISO 9001:2008

- Standard:GB

- Surface Treatment:Spray-Paint

- Manufacturing Process:Casting

- Material:Cast Steel

- Color:Customized

Base Info

- Model NO.:trituradora de piedra

- Special Material:High Manganese

- Transport Package:Wooden Tray

- Specification:GB

- Trademark:DENP

- Origin:China

- HS Code:84742090

- Production Capacity:5000t,Y

Description

Basic Info.

Model NO. trituradora de piedra Special Material High Manganese Transport Package Wooden Tray Specification GB Trademark DENP Origin China HS Code 84742090 Production Capacity 5000t/YProduct Description

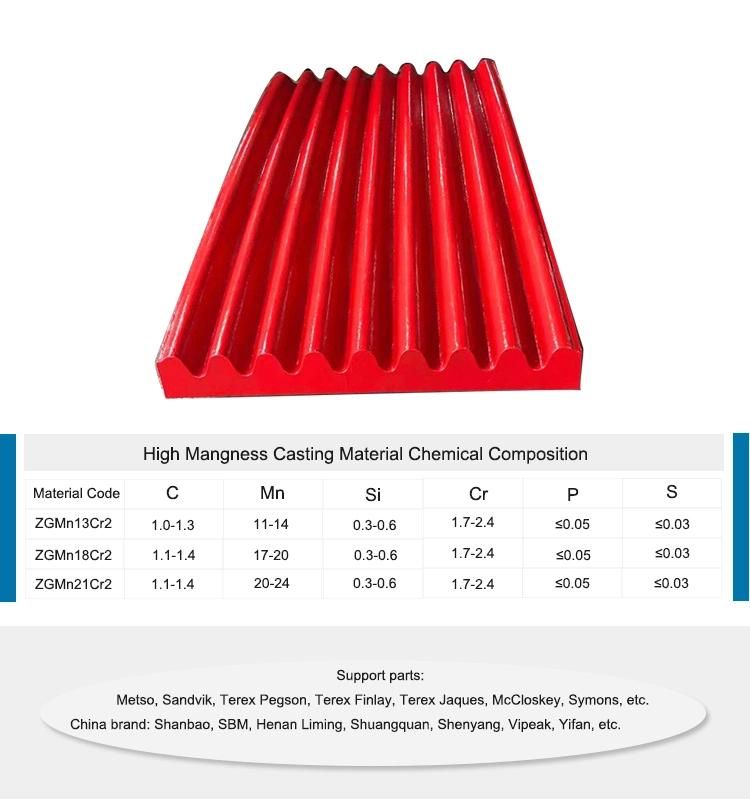

Mn18, Mn22 Manganese replacement for Stone crusher form foundry| Material | C | Mn | Si | Cr | Mo | Ni | P | S |

| Mn13Cr2 | 1.0~1.3 | 11~14 | 0.3~0.6 | 1.7~2.4 | 0.1~1.0 | ≤0.03 | ≤0.05 | ≤0.03 |

| Mn18Cr2 | 1.1~1.4 | 17~20 | 0.3~0.6 | 1.7~2.4 | 0.1~1.0 | ≤0.03 | ≤0.05 | ≤0.03 |

| Mn21Cr2 | 1.1~1.4 | 20~24 | 0.3~0.6 | 1.7~2.4 | 0.1~1.0 | ≤0.03 | ≤0.05 | ≤0.03 |

| Cr26 | 2.3~3.3 | ≤1.0 | ≤1.2 | 23~30 | 0.1~3.0 | 0.1~1.0 | ≤0.06 | ≤0.04 |

Jaw plates (fixed and swing jaw plate) are the most important wear parts of jaw crusher. We use high manganese steel with chrome as the material to make sure the quality.

Raw materials are crushed to small aggregates between movable jaw plate and fixed jaw plate. So movable jaw plate impacts raw material directly during the operation-time. Supposing that it is damaged, raw materials will impact the movable jaw of jaw crusher and the machine service-life will also be affected.