Hydraulic Motor Driving Center Thickener

Blackstone International Company Limited- Type:Thickening & Dewatering

- Certification:ISO9001:2000

- Energy Saving:Energy Saving

- Condition:New

Base Info

- Model NO.:Hydraulic Motor Driving Center Thickener

Description

Basic Info.

Model NO. Hydraulic Motor Driving Center ThickenerProduct Description

Hydraulic Motor Driving Center Thickener

[Introduction] Thickener driven by central hydraulic motor and hydraulic automatic hoisting rake.

[Precipitation area] 25-7853m2

[Application] It is mainly used for clarification and concentration of pulp to achieve the purpose of dehydration. It can also be used for dehydration of solid-liquid separation in chemical and metallurgical industries.

[Improvement] The maximum inner diameter can reach 100M.

Advantages

- Increase the degassing tank to avoid solid particles adhering to bubbles.

- The feeding pipe is located below the liquid level in order to prevent the gas from entering when feeding.

- The feeder moves downhole and is equipped with a receiving tray. The slurry feeds uniformly and drops smoothly, which effectively prevents the overturning phenomenon caused by the rock pressure.

- Increase overflow weir to make material flow according to the prescribed travel and prevent short-circuit phenomenon.

- The overflow weir is serrated, which improves the suction phenomenon of local drainage caused by the uneven overflow weir.

- Change the rake tooth profile from oblique to curve to make the pulp flow to central rake, and form centripetal pressure, which makes the bottom flow concentration of ore discharging high, thus increasing the processing capacity.

Structure

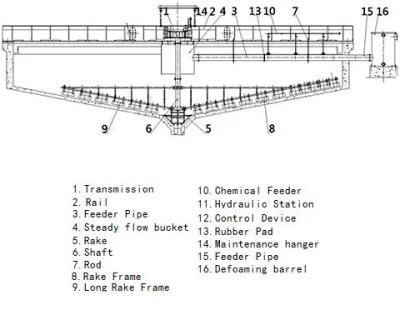

The thickener is mainly composed of the transmission device, bridge, charging device, feeding pipe, fixed cylinder, distributor, scraper, shaft, long rake, short rake, suspender, electronic control device, hydraulic station, and maintenance hanger.

With flocculation technology, the pulp is directly fed into the concentration zone of the thickener, and a filter bed is formed in the pond. There are no flocculating fine particles in the pulp fed from the bottom. When the pulp is washed up by water and passed through the filter bed, it collides with the particles of the layer. Because of the function of flocculant, it is combined with other particles and then sinks, thus increasing the concentration of the bottom slurry and the concentration of the upper overflow water.

As a result of the use of flocculants, the particles are easy to form aggregates, the settling speed is greatly accelerated, and the treatment capacity per unit area is significantly improved, which is 5 to 8 times that of the traditional concentrator.

Technical Parameter

Model | Diameter m | Depth m | Area m2 | Rake Revolution min/r | Rake Lifting mm | Capacity t/d | Power kw |

NZY-6 | 6 | 3~3.2 | 25 | 2.5~5 | 350 | 50~100 | 3 |

NZY-9 | 9 | 3.5~3.8 | 63.6 | 3~5 | 350 | 120~175 | 3 |

NZY-12 | 12 | 3.5~3.8 | 113 | 4~7 | 350 | 200~300 | 4 |

NZY-15 | 15 | 4~4.5 | 176 | 5~10 | 450 | 350~400 | 5.5 |

NZY-18 | 18 | 4~4.5 | 254 | 8~12 | 450 | 600~800 | 5.5 |

NZY-20 | 20 | 4~4.5 | 314 | 8~12 | 450 | 800~1000 | 7.5 |

NZY-24 | 24 | 4.5~5.5 | 450 | 9~12 | 450 | 1000~1300 | 7.5 |

NZY-30 | 30 | 4.5~5.5 | 706 | 10~14 | 450 | 1500~1800 | 11 |

NZY-38 | 38 | 6.5~8 | 1134 | 15~22 | 600 | 1800~2200 | 15 |

NZY-40 | 40 | 6.5~8 | 1256 | 15~22 | 600 | 2200~2400 | 15 |

NZY-45 | 45 | 6.5~8 | 1590 | 15~22 | 600 | 2400~2800 | 15 |

NZY-53 | 53 | 6.5~8 | 2206 | 15~22 | 600 | 3000~3500 | 15 |

NZY-60 | 60 | 7~8.5 | 2827 | 16~50 | 600 | 3500~5000 | 18.5 |

NZY-75 | 75 | 8~10 | 4418 | 20~80 | 800 | 7500~10000 | 22 |

NZY-100 | 100 | 8~10 | 7853 | 35~80 | 800 | 10000~15000 | 30 |