Hydrocyclone Assembly

Blackstone International Company Limited- Type:Hydrocyclone Assembly

- Certification:ISO9001:2000

- Energy Saving:Energy Saving

- Condition:New

Base Info

- Model NO.:Hydrocyclone Assembly

Description

Basic Info.

Model NO. Hydrocyclone AssemblyProduct Description

Hydrocyclone Assembly

[Introduction] Cyclone set with high classification efficiency.

[Capability] less than 2500m3/h.

[Application] Hydraulic cyclone set is used to separate heavy coarse granular mud and sand, classify, concentrate, dehydrate, desliming, desanding, washing, superfine classification, etc.

[Improvement] Gate-free valves are installed at the feeding ports of each mine. The valves are reliable in operation and have small resistance to movement. Meanwhile, the size of the valves is very small, which reduces the diameter of the whole cyclone group.

Advantages

- The interior is lined with wear-resistant rubber, including the box body, pipelines and key parts, etc. are all covered with rubber.

- Cyclone set runs smoothly and has high classification efficiency.

- The hydrocyclone unit can be equipped with automatic control system for classification, which can set parameters for the characteristics of black, non-ferrous and chemical minerals, non-metallic minerals and building materials minerals respectively. The liquid level of the pump pool and the flow rate, outlet pressure, slurry concentration and motor speed of the slurry pump can be detected and adjusted automatically to ensure the stability of the inlet index of the hydrocyclone.

- The parameters are adjusted according to the feedback data of the overflow concentration and flow rate of the hydrocyclone, so that the index is always in the optimum range required.

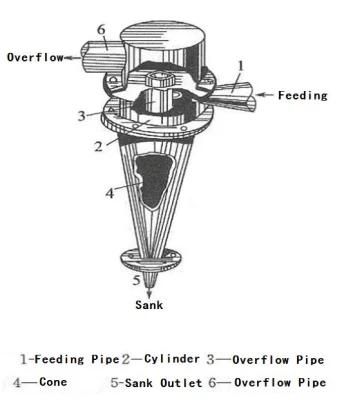

Structure

When the mixed liquid to be separated enters the hydrocyclone at a certain pressure from the feed port of the hydrocyclone, a strong three-dimensional elliptical strong rotational shear turbulence is generated. Due to the different density of particles, the centrifugal force, centripetal buoyancy, fluid drag force and other sizes are different. Under centrifugal sedimentation, most of the coarse particles (or heavy phases) are discharged through the underflow port of the cyclone, while most of the fine particles (or light phases) are discharged by the overflow pipe, thus achieving the purpose of separation and classification.

Technical Parameter

Model | Specification | Capacity m3/h | Particle Size μm | Overflow Outlet Diameter mm | Sank Outlet Diameter mm |

XC II F 150 | 150 | 10 ~23 | 25 ~74 | 30 ~50 | 8~22 |

XC II F 200 | 200 | 17 ~38 | 28 ~80 | 40 ~65 | 16 ~32 |

XC II F 250 | 250 | 24 ~53 | 30 ~82 | 65~100 | 16 ~40 |

XC II F 300 | 300 | 40~100 | 36 ~90 | 65~120 | 20 ~40 |

XC II F 350 | 350 | 56~118 | 40~100 | 80~120 | 30 ~70 |

XC II F 375 | 375 | 74~157 | 42~105 | 90~135 | 30 ~70 |

XC II F 450 | 450 | 90~192 | 44~110 | 100~150 | 30 ~70 |

XC II F 500 | 500 | 128~300 | 50~115 | 130~220 | 35~100 |

XC II F 550 | 550 | 155~368 | 52~120 | 140~240 | 35~100 |

XC II F 600 | 600 | 200~468 | 57~125 | 160~260 | 65~110 |

XC II F 660 | 660 | 237~524 | 60~130 | 180~280 | 80~150 |