System Sand Machine Impact Crusher Plate Hammer

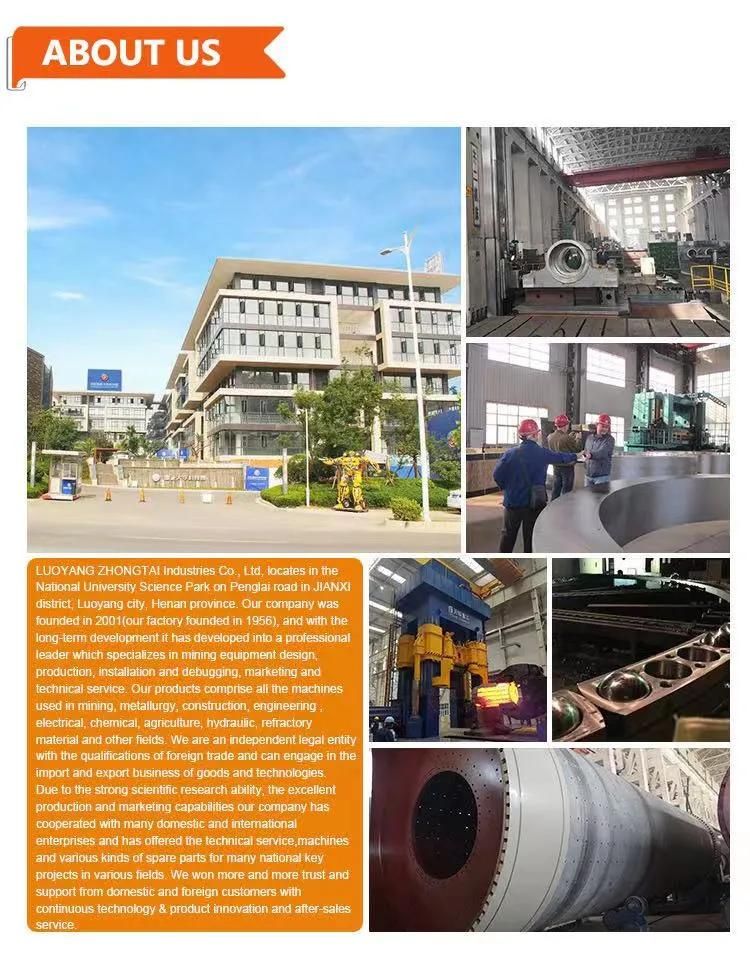

Luoyang Zhongtai Industries Co., Ltd.- After-sales Service:Online Service

- Warranty:1 Year

- Material:High Chrome Crusher Hammer

- Control:Spectrometer Chemical Analysis and Control While P

- Molding Process:Water-Glass Sand Casting or Lost Form Casting

- Melting Facility:Medium Frequency Electric Furnace

Base Info

- Model NO.:hammer

- Heat Treatment:Anneal, Quenching, Tempering

- Testing:Hardness, Flaw Detector Test

- Certificate:ISO9001~2008 Passed; Bureau Veritas

- Quality Guarantee:One Year Against Manufacturing Defeat

- Transport Package:Simple Packing

- Specification:custom

- Trademark:ZTIC

- Origin:Luoyang, Henan

- Production Capacity:3000PCS,Year

Description

Overview

Product Description

Crusher Hammer

Crusher hammer such as clinker crusher hammer and raw material hammer is one of the core parts of hammer crusher.Our hammer crusher parts:crusher hammer use refining, vacuum casting,directional solid and etc technicals to increase the grain refinement and make the hammers performance achieve the best performance. Hammer hasrdness is the most essential factor in determining hammer life so the hammer head must be extremely hard and resistant to wear. Our company uses a specical method of heat treating that make the hammer hardness and wear resistance reach the best state of cooperation, thus greatly improve hammer's service life time. According to the material, our crusher hammer can be dividede into: high manganese hammer, high chrome hammer, bimetal composited hammer. The bimetal composite hammer, our national patent product, is called "Hard Stone Killer" by many clients. Our crusher hammer generally can save users 1/3 equipment investment, saving 1/2 the power consumption, save a lot of maintenance costs.

ZTIC is the leader in offering wear solutions to crusher operators in China. We provide wear parts with designs and alloys specifically developed for each application and specific location within each crusher.Our crusher parts are made of manganese steel - the toughest and most wear-resistant steel available. In addition to the crusher components listed above, we also make cast components for the crusher itself such as the pitman arm, side plates, cheek plates, etc.

1.High Chrome Crusher Hammer

For our high chrome hammer or hammer block,while producing:

Adopt progressive solidification process, makes Cr7C3 type carbide vertical growth against the working face. In the case of not lower the toughness of the parts, at the same time the macro-hardness of the working face and micro hardness of Cr7C3 type also improved.

Use multiple micro-alloyed methods to receive dispersion strengthened and progressive hardening.

Use annealing, quenching, tempering heat treatment process to make the blow bars'surface hardness reaches 58-65HRC.

CITIC IC STONE HAMMER MILL CRUSHER Hammers

Hammer crusher is suitable for crushing brittle, resistant plate, water content not high materials. In construction industry,chemical industry, electric power,mining,metallurgy and other industries, small rock crusher (or hammer block) are used to crush limestone, shale,coal,gypsum,chalk,asbestos ore,coke etc.Usually in the ore it contains SiO2,Ai2O3 etc high hardness stone which hardness up to 1100~1800HV,viewing from theoretical point,the hardness ratio requirment between hammer (or hammer block) (HM) and crushed material should be no less than 0.8,that means the hardness of the hammer (block) working parts should be above 1375-2250HV,so that the hammer can withstand the wearing and cuting from the crushed material and receive good wear-resisting performance. Nowadays, single material can't have the conbination of high hardenss and toughness, we specially design thesmall rock crusher (or hammer block) which working parts using high chromium cast iron and assembly parts using alloy steel to receive good performance servce.Working in with our resistant plate will get the best performance.

Our high chromium cast iron hammer (or hammer block) adopt the lost foam mold vibration casting. Under vacuum negative pressure vibration casting, we not only can refine grain, improve the density of the casting parts, but also make the gas and inclusion up floating, and purify the chromium iron water, so as to improve the comprehensive mechanical properties of the parts, greatly improve the service life and fully satisfy the users.

Details of CITIC IC STONE HAMMER MILL CRUSHER Hammers

High Chrome Crusher Hammer

Material

Cr20Mn2,Cr26Mn2

Control

Spectrometer chemical analysis and control while producing

Molding Process

Water-glass sand casting or lost form casting

Melting facility

Medium frequency electric furnace

Heat Treatment

Anneal, quenching, tempering

Quality Guarantee

One year against manufacturing defeat

Testing

Hardness, flaw detector test

Certificate

ISO9001~2008 Passed; BUREAU VERITAS

2.High Manganese Hammer

The high Mn hammer head serious product make by our company ,while producing:

use the molding cold iron in the working part in order to increase the compactness of working part.

Use the refining techniques of furnace bottom blowing argon to quick-wear part. We use diversified qualitative change to increase grain boundary strength.

Use diversified inoculation to refined grain.

These High manganese little hammer for clinker crusheringinduce the hammer made by our company with higher wear resistant safety and reliability nature. Our customers are satisfied with our hammer, and our goods are exported to serious countries.

GENERAL DESCRIPTION

Wear components for crushing processes are subjected to severe impact and high abrasion, requiring components made from impact resistant and abrasion resistant alloys.

We increase crusher availability through:

? Increased wear life

? Less on-going wear part maintenance

? Designs and tools for quicker change out

Hammer crusher wearparts:

Hammer crusher wearparts.

We produce Hammers in One and Two-Piece styles, Grates, Breaker Blocks, Side Liners, Breaker Bar Sleeves, Rotor Hubs, Complete Rotor Assemblies, Top Cover Liners and Throat Collars.

?Grates

? Breaker Blocks

? Side Liners

? Breaker Bar Sleeves

? Rotor Hubs

? Complete Rotor Assemblies

? Top Cover Liners

? Throat Collars

A: 1. More than 30 years experience.

2.We are the leading professional supplier of mining machinery, construction machinery, machines casting and forged parts

3. All products achieved ISO9901:2000 quality management certificate and CE, ROHS certificates.

Q:Delivery time

A: parts lead time 1-2months, machines 2-3months.

Q:Payment terms

A: Accept payment type: T/T, L/C, Western union,Cash.

30% deposit when signed contract. Full payment paid before shipping

Q: Quality warranty?

A: guarantee time: one year for main machinery. If something wrong we will provide the technical advice and find solution immediately. For those wearing parts we guarantee high quality parts for long-term supply.

Q: After sales service?

A: we can supply technical guide for machines running test and parts maintenance if end user needs.

System sand machine impact crusher plate hammer

Crusher Hammer

Crusher hammer such as clinker crusher hammer and raw material hammer is one of the core parts of hammer crusher.Our hammer crusher parts:crusher hammer use refining, vacuum casting,directional solid and etc technicals to increase the grain refinement and make the hammers performance achieve the best performance. Hammer hasrdness is the most essential factor in determining hammer life so the hammer head must be extremely hard and resistant to wear. Our company uses a specical method of heat treating that make the hammer hardness and wear resistance reach the best state of cooperation, thus greatly improve hammer's service life time. According to the material, our crusher hammer can be dividede into: high manganese hammer, high chrome hammer, bimetal composited hammer. The bimetal composite hammer, our national patent product, is called "Hard Stone Killer" by many clients. Our crusher hammer generally can save users 1/3 equipment investment, saving 1/2 the power consumption, save a lot of maintenance costs.

ZTIC is the leader in offering wear solutions to crusher operators in China. We provide wear parts with designs and alloys specifically developed for each application and specific location within each crusher.Our crusher parts are made of manganese steel - the toughest and most wear-resistant steel available. In addition to the crusher components listed above, we also make cast components for the crusher itself such as the pitman arm, side plates, cheek plates, etc.

1.High Chrome Crusher Hammer

For our high chrome hammer or hammer block,while producing:

Adopt progressive solidification process, makes Cr7C3 type carbide vertical growth against the working face. In the case of not lower the toughness of the parts, at the same time the macro-hardness of the working face and micro hardness of Cr7C3 type also improved.

Use multiple micro-alloyed methods to receive dispersion strengthened and progressive hardening.

Use annealing, quenching, tempering heat treatment process to make the blow bars'surface hardness reaches 58-65HRC.

CITIC IC STONE HAMMER MILL CRUSHER Hammers

Hammer crusher is suitable for crushing brittle, resistant plate, water content not high materials. In construction industry,chemical industry, electric power,mining,metallurgy and other industries, small rock crusher (or hammer block) are used to crush limestone, shale,coal,gypsum,chalk,asbestos ore,coke etc.Usually in the ore it contains SiO2,Ai2O3 etc high hardness stone which hardness up to 1100~1800HV,viewing from theoretical point,the hardness ratio requirment between hammer (or hammer block) (HM) and crushed material should be no less than 0.8,that means the hardness of the hammer (block) working parts should be above 1375-2250HV,so that the hammer can withstand the wearing and cuting from the crushed material and receive good wear-resisting performance. Nowadays, single material can't have the conbination of high hardenss and toughness, we specially design thesmall rock crusher (or hammer block) which working parts using high chromium cast iron and assembly parts using alloy steel to receive good performance servce.Working in with our resistant plate will get the best performance.

Our high chromium cast iron hammer (or hammer block) adopt the lost foam mold vibration casting. Under vacuum negative pressure vibration casting, we not only can refine grain, improve the density of the casting parts, but also make the gas and inclusion up floating, and purify the chromium iron water, so as to improve the comprehensive mechanical properties of the parts, greatly improve the service life and fully satisfy the users.

Details of CITIC IC STONE HAMMER MILL CRUSHER Hammers

High Chrome Crusher Hammer

Material

Cr20Mn2,Cr26Mn2

Control

Spectrometer chemical analysis and control while producing

Molding Process

Water-glass sand casting or lost form casting

Melting facility

Medium frequency electric furnace

Heat Treatment

Anneal, quenching, tempering

Quality Guarantee

One year against manufacturing defeat

Testing

Hardness, flaw detector test

Certificate

ISO9001~2008 Passed; BUREAU VERITAS

2.High Manganese Hammer

The high Mn hammer head serious product make by our company ,while producing:

use the molding cold iron in the working part in order to increase the compactness of working part.

Use the refining techniques of furnace bottom blowing argon to quick-wear part. We use diversified qualitative change to increase grain boundary strength.

Use diversified inoculation to refined grain.

These High manganese little hammer for clinker crusheringinduce the hammer made by our company with higher wear resistant safety and reliability nature. Our customers are satisfied with our hammer, and our goods are exported to serious countries.

GENERAL DESCRIPTION

Wear components for crushing processes are subjected to severe impact and high abrasion, requiring components made from impact resistant and abrasion resistant alloys.

We increase crusher availability through:

? Increased wear life

? Less on-going wear part maintenance

? Designs and tools for quicker change out

Hammer crusher wearparts:

Hammer crusher wearparts.

We produce Hammers in One and Two-Piece styles, Grates, Breaker Blocks, Side Liners, Breaker Bar Sleeves, Rotor Hubs, Complete Rotor Assemblies, Top Cover Liners and Throat Collars.

?Grates

? Breaker Blocks

? Side Liners

? Breaker Bar Sleeves

? Rotor Hubs

? Complete Rotor Assemblies

? Top Cover Liners

? Throat Collars

FAQ

Q: Why we believe in luoyang zhongtai industries co., ltd:

A: 1. More than 30 years experience.

2.We are the leading professional supplier of mining machinery, construction machinery, machines casting and forged parts

3. All products achieved ISO9901:2000 quality management certificate and CE, ROHS certificates.

Q:Delivery time

A: parts lead time 1-2months, machines 2-3months.

Q:Payment terms

A: Accept payment type: T/T, L/C, Western union,Cash.

30% deposit when signed contract. Full payment paid before shipping

Q: Quality warranty?

A: guarantee time: one year for main machinery. If something wrong we will provide the technical advice and find solution immediately. For those wearing parts we guarantee high quality parts for long-term supply.

Q: After sales service?

A: we can supply technical guide for machines running test and parts maintenance if end user needs.