High Performance Small Spring Cone Crusher Hydraulic Cone Crusher

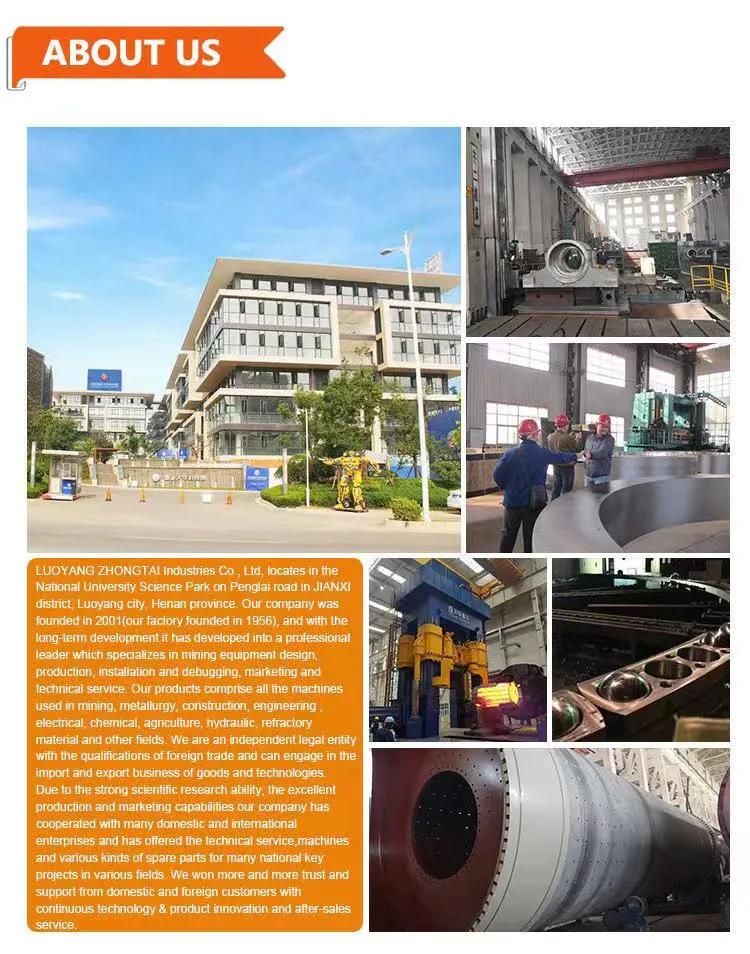

Luoyang Zhongtai Industries Co., Ltd.- Type:Cone Crusher

- Motor Type:AC Motor

- Motor Power:110kw

- Application:Mine

- Materials:Limestone

- Outlet Size:150-300mm

Base Info

- Model NO.:Cone Crusher

- Inlet Size:150×750mm

- Condition:New

- Warranty:a Year

- After-sales Service:Twenty Four Hour Online

- Crushingtype:Secondary Crushing

- Input Size:30-460mm

- Output Size (mm):5-70

- Capacity (T/H):33-2200

- Applications:Aggregate Field,Concrete Mixing Plant,Dry Mortar

- Weight (Kg):4500-89500

- Power (Kw):75-600

- Feed Opening (mm):40-550

- Max Model:Gpy2000,550

- Transport Package:Dp Series Single Cylinder Hydraulic Cone Crusher

- Specification:DP Series Single Cylinder Hydraulic Cone Crusher

- Trademark:ZTIC

- Origin:Luoyang, Henan

- Production Capacity:1000PCS,Year

Description

Introduction of cone crusher

Cone crusher (spring cone crusher) can crush materials of above medium hardness. And it is widely used in metallurgy, building, hydropower, transportation, chemical industry, etc. When used with jaw crusher, it can be used as secondary, tertiary or quaternary crushing. Generally speaking, the standard type of Symons cone crusher is applied to medium crushing. The medium type is applied to fine crushing. The short head type is applied to coarse fine crushing. As casting steel technique is adopted, the machine has good rigidity and large high strength.Cone crusher technical parameters for reference

FAQ

FAQAfter Sales Service

ZTIC Heavy Industries is your business partner in the After Market.

ZTIC able to provide:

1. ENGINEERED SPARES - DESIGN AND MANUFACTURING

2. LARGE VOLUME STEEL AND IRON CASTING FOUNDARIES

3. HUGE MACHINE SHOP CAPABILITIES

4. TRAINING PROGRAMMES

5. PREVENTATIVE MAINTENANCE PROGRAMS

6. PREVETATIVE MAINTENANCE SERVICES

7. COMPREHENSIVE MAINTENANCE PROGRAMS