High Capacity and Quality XJk Flotation Separator Price

Gongyi Hengchang Metallurgical Building Material Equipments Plant- Type:Flotation Separator

- Voltage:380V

- Weight:<1T

- Material:Carbon Steel

- Material Feature:Heat Resistant

- Certification:ISO9001:2008

Base Info

- Model NO.:XJK

- Energy Saving:Energy Saving

- Warranty:1 Year

- Color:Multi Color

- Customized:Customized

- Condition:New

- Name:High Capacity and Quality Xjk Flotation Separator

- Keywords:Flotation Separator

- Installation:Engineer Guide

- Impeller Speed:240-500 R,Min

- Power:3-15kw

- Price:Negotiation

- Capacity:0.12-7 M3,Min

- MOQ:1 Set

- Brand:Hengchang

- Quality:High Quality

- Transport Package:Container

- Specification:SJK

- Trademark:Hengchang

- Origin:China

- HS Code:8474100000

- Production Capacity:100 Set,Day

Description

Basic Info.

Model NO. XJK Energy Saving Energy Saving Warranty 1 Year Color Multi Color Customized Customized Condition New Name High Capacity and Quality Xjk Flotation Separator Keywords Flotation Separator Installation Engineer Guide Impeller Speed 240-500 R/Min Power 3-15kw Price Negotiation Capacity 0.12-7 M3/Min MOQ 1 Set Brand Hengchang Quality High Quality Transport Package Container Specification SJK Trademark Hengchang Origin China HS Code 8474100000 Production Capacity 100 Set/DayProduct Description

1.Brief IntroductionHigh Capacity And Quality XJK Flotation Separator Price machine is suitable for separation of non-ferrous metals, ferrous metals, precious metals, non-metallic mineral and chemical raw materials, recovering useful minerals. This machine has the features of the big suction capacity and low power consumption. Every slot has the triple function of suction, grout and flotation which become the complete flotation circuit without any auxiliary equipment installing the machine in a actinic line it will be easier for the flow process change, the rational slurry cycle and furthest reducing the coarse sand sinking...

2.Technical Data :

| Model | XJK-2(A) | XJK-3(A) | XJK-4(A) | XJK-5(A) | XJK-6(A) | XJK-7(A) |

| Slot Volume(m3) | 0.23 | 0.35 | 0.62 | 1.1 | 2.8 | 5.8 |

| Impeller Dia.(mm) | 250 | 300 | 350 | 500 | 600 | 750 |

| Impeller Speed(r/min) | 500 | 483 | 400 | 330 | 280 | 240 |

| Capacity(m3/min) | 0.12-0.28 | 0.18-0.5 | 0.3-0.9 | 0.6-1. 6 | 1.5-3.5 | 3-7 |

| Slot Size(mm) | 600×600 ×650 | 700 × 700 ×750 | 820×900 ×850 | 1100×1100 ×1000 | 1750×1600 ×1100 | 2200×2200×200 |

| Power(Kw) | 3/2 slots | 3/2 slots | 3 | 5.5 | 11 | 15 |

| Weight(kg/Slot) | 1158/4 | 1720/4 | 2500/4 | 4514/2 | 4514/1 | 7066/4 |

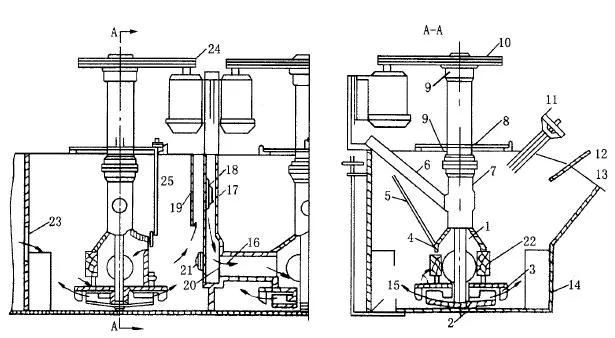

3.Working Principle

- After intensively mixed, the pulp and medicaments are fed to the groove bottom of the first tank.

(2) When the impeller of the flotation machine for gold ore begins to rotate, negative pressure is formed, making the air and pulps at the bottom and middle part of the tank enter the mixing zone. The pulp, air and medicaments are then mixed in the mixing zone.

(3) As a result of the cenrifugal force, the blended pulps are lead to the mineralization area. The air is in full contact with the coal particle and forms mineralized discharged by the scraping tool. Finally, clean coal foam is produced by this flotation machine.

(4) Coal particles that are not mineralized will be remixed, re-mineralized and re-separate through the recycle hole and the upper intake.

(5) The left pulp that are not sucked by the impeller enters intor the third tank after going through the process of the first tank, thus, flotation machine for gold ore runs in cycle and discharges ore pulp through the tailing box of the flotation machine.

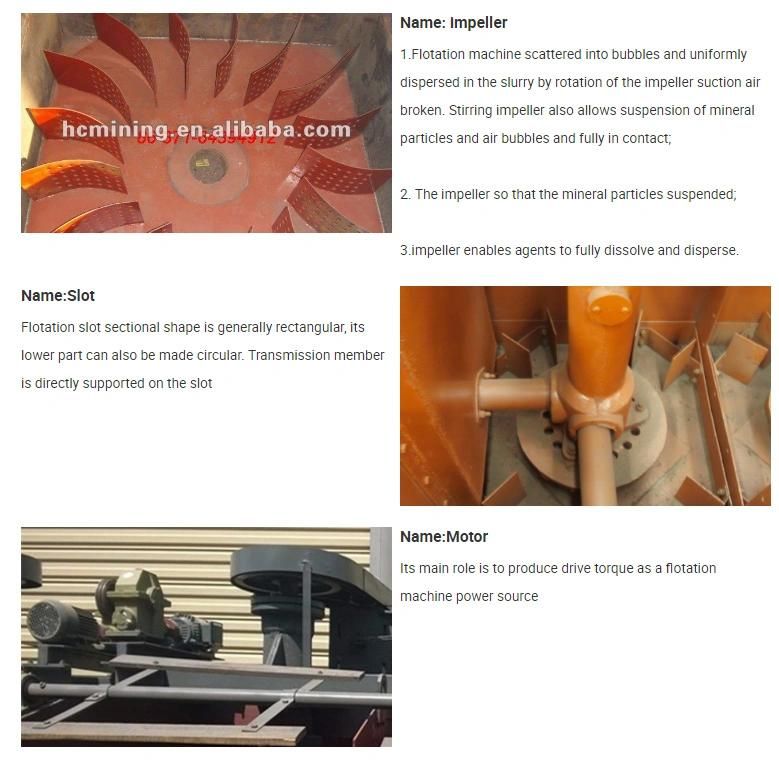

4.Detailed Images

5.Main Features

1.Excellent air-absorption capacity

2.Low energy consumption

3.Optimized design, the mineral slurry loops reasonably in cells without auxiliary equipment

4.Self-control functions

5.Special designed impeller which can produce upper ans lower circulation of mineral slurry respectivel.

6.Working and Delivery

7.Our Company

Gongyi Hengchang Metallurgy Building Material Equipments plant is a professional manufacturer specializing in the production of mineral beneficiation equipments, sand and stone crushing equipments, briquetting equipments, coal preparation equipments, drying and calcining equipments, cement plant equipments and compound fertilizer equipments. The products are widely used in mineral processing, metallurgy, building materials, chemicals, electricity, petroleum, coal, transportation, fertilizer , gas industry etc.