Jaw Crusher Ball Mill for Hard Rock Mining Gold and Silver Ore and Processing Plant

Jiangxi Hengchang Mining Machinery Manufacturing Co., Ltd.- Type:Ball Mill

- Motor Type:AC Motor

- Motor Power:7.5KW

- Rotationl Speed:16-18r,min

- Application:Mine

- Materials:Gold

Base Info

- Model NO.:GM0921

- Condition:New

- Name:Gold Wash Plant

- Model:1200b

- Capacity:0.8-1.2 T,H

- Weight:5500 Kg

- Transport Package:FCL or LCL

- Specification:Wet pan mill

- Trademark:Hengchang

- Origin:China

- HS Code:8474202000

- Production Capacity:100 Sets,Month

Description

Basic Info.

Model NO. GM0921 Condition New Name Gold Wash Plant Model 1200b Capacity 0.8-1.2 T/H Weight 5500 Kg Transport Package FCL or LCL Specification Wet pan mill Trademark Hengchang Origin China HS Code 8474202000 Production Capacity 100 Sets/MonthProduct Description

Jaw Crusher Ball Mill for Hard Rock Mining Gold and Silver Ore and Processing Plant

Jaw Crusher Ball Mill for Hard Rock Mining Gold and Silver Ore and Processing Plant1. Gold Wash Plant Introduction:

Gravity gold processing is the most traditional method of extracting gold in rock gold mine used widely. It is more as a secondary process to recover coarse gold in the grinding circuit to create favorable conditions for the flotation and cyanidation. Because of its efficiency in capturing single coarse gold, so for placer gold extraction, the process is also in dominant position.

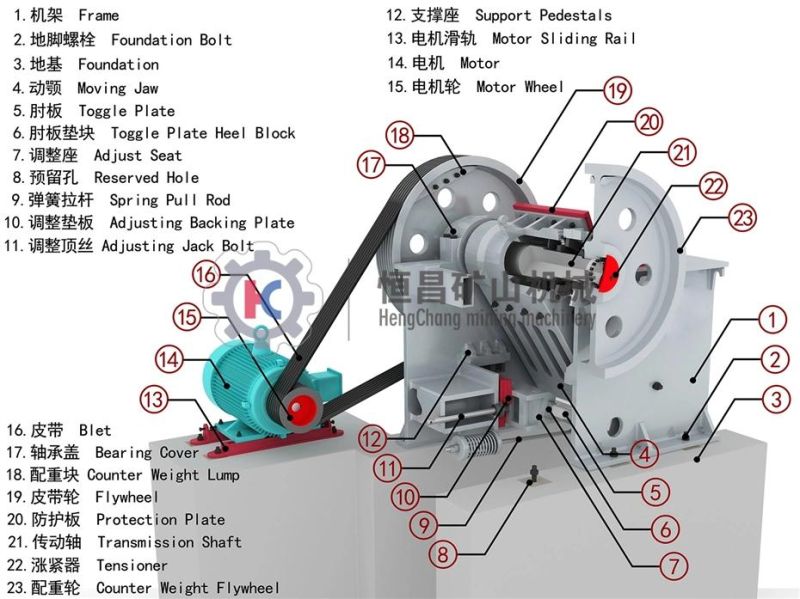

1. Crushing: Use jaw crusher to crush the raw material into 0-50mm particles.

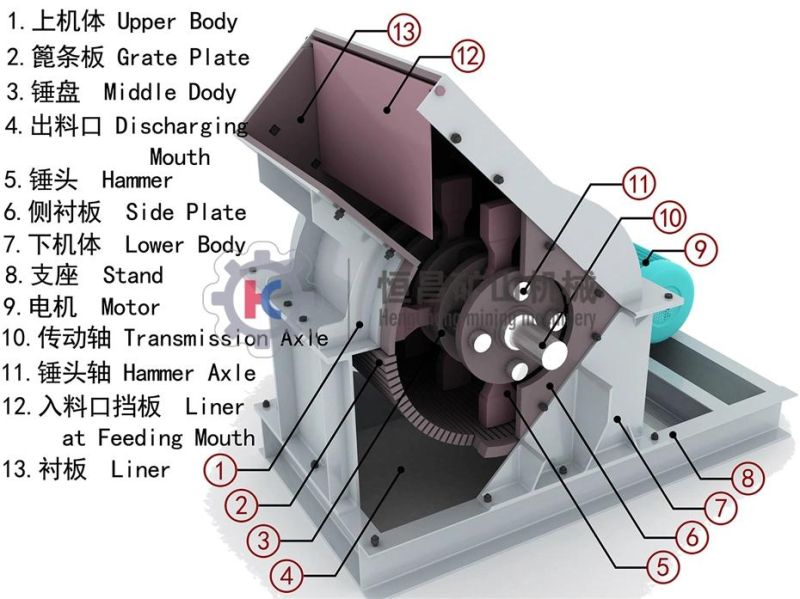

2. Fine crushing: Use hammer mill to crush the particle materials into powder(0-2mm).

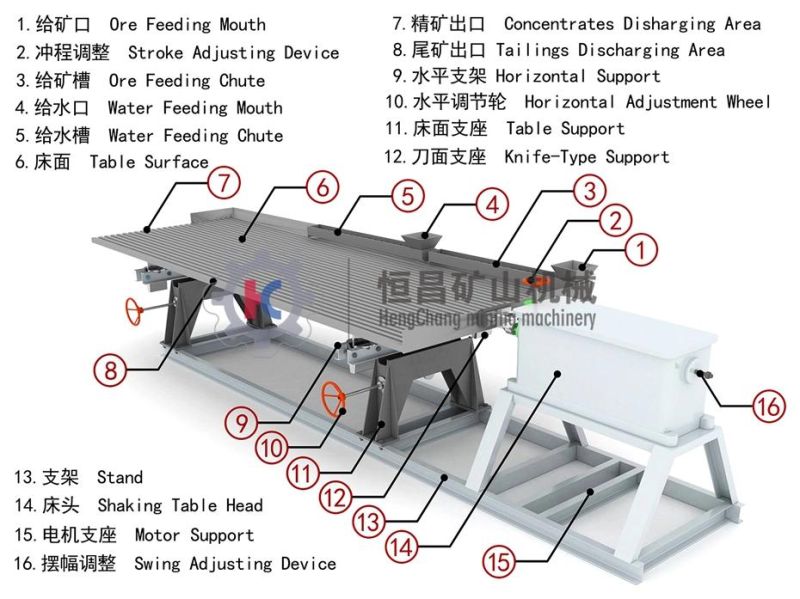

3. Gravity concentration: Use gold shaking table to separate the gold concentrate from the powder(0-2mm).

2. Gold Wash Plant Structure:

Jaw crusher is often used as primary and secondary crusher for mining, metallurgy, construction and some other industries. It takes large pieces of rock, ore, concrete, or other materials, and crush them down to smaller sizes for further processing in a ball mill or hammer crusher. It is widely used in mining, metallurgy, building materials, road, railway, road, slag for crushing various materials with compression strength less than 350 Mpa.

Hammer mill is a fine crushing machine whose purpose is to shred or crush aggregate material into smaller particulates (under 2mm) by the repeated blows of little hammers. Hammer mill is mainly used for crushing various soft and medium-hard ore, whose compression strength is not higher than 320MPa, such as coal, salt, chalk, gypsum, blocks, limestone, glasses, and phosphate, etc.

Ball mill is the important equipment for recrushing the materials after they are primarily crushed. It is an efficient tool for grinding various materials into powder. There are two ways of grinding: the dry process and the wet process. It can be divided into tabular type and flowing type according to different forms of discharging material. Ball mill is widely used in metallurgy, chemical, mining, cement, construction, industrial and mining industries etc.

Gold haking table is one of the main equipment of gravity concentration, which is suitable for rough separation and concentration. It is widely used in separating gold, tungsten, tin, tantalum, niobium and other rare metals and precious metal ore. Can be used for roughing, concentration, scavenging different operations, separating coarse sand (2-0.5mm), fine sand (0.5-0.074mm), slime (-0.074mm) of different grain grade.

3. Successful Case

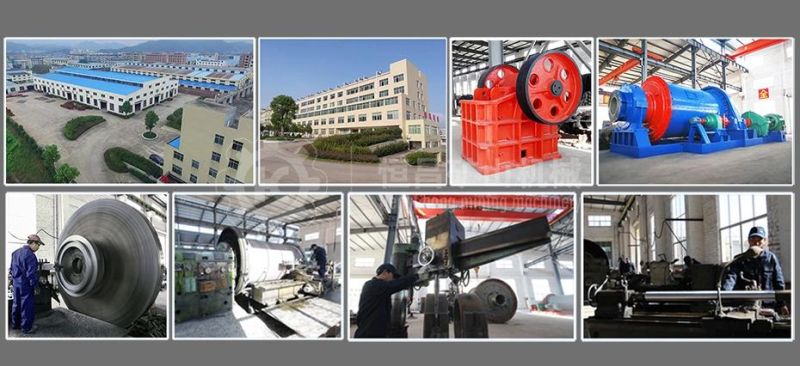

4.About our factory:

4.About our factory:Jiangxi Hengchang Mining Machinery Manufacturing Co., Ltd. is located in No.3 Chuangye Road. Guzhang In dustrial Park. Shicheng County. Ganzhou City. Jiangxi Province. China.Our company is engaged in the mineral processing equipment research, development, design and production for many years history, has accumulated rich experience in design and production. Enterprise in mineral processing equipment industry has had a positive effect, set up the good reputation. And mainly the manufacture of the products like as Shaking table. Flotation equipment. Crushing equipment. Magnetic separator. Screening equipment. Classifying equipment. Agitation tank, Feeding equipment. Gravity separation equipment. Wet separation equipment. Spiral chute. Saw-tooth wave jig and Diaphragm Jig. Grinding equipment. Ball mill. Slurry pump. Centrifugal pump, Conveying equipment.

We manufacture various types of mineral processing machinery and equipment according to our customers' requirements. Our products are widely used for sorting gold, silver, copper, iron, tungsten,lead. zinc. tin. molybdenum, nickel, tantalum, niobium, manganese ore, coal, monazite, rutile,diamonds, other precious metals and precious metals mine, and for the flotation colored, black metal,precious metals and other minerals. And we have export qualifications, our products sell well all over the world for several years, especially exported to Brazil. India. Indonesia.South Africa. Somalia, Philippines. Malaysia. Sudan, Nigeria. Iran, Russia, Ghana. Kazakhstan Kyrgyzstan.Cambodia,Vietnam,Korea,Mongolia and other countries.

6. FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.not dealer.Direct factory sale makes price more competitive.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.If you have another question, pls feel free to contact us.