PE200X300 Mini Mobile Stone Jaw Crusher Machine

Gongyi Hengchang Metallurgical Building Material Equipments Plant- Type:Jaw Crusher

- Motor Type:AC Motor

- Motor Power:7.5kw

- Application:Construction

- Materials:Stone,Ore,Wood,Charcoal etc. to Be Broken

- Outlet Size:50-100mm

Base Info

- Model NO.:PE200X300

- Inlet Size:200X300mm

- Condition:New

- Material:Manganese Steel

- Warranty Period:One Year Excluding Wearing Parts

- Motor:It′s up to You

- After-Sale Technology Support:Engineers Available to Provide Field Services

- After-Sale Service Supply:Life-Long Period Available

- Spare Parts Supply:Life-Long Period Available

- Installation:Engineer′s Guide Available

- Certificate:Ce,ISO9001:2012

- Max.Input Size:165mm

- Transport Package:Standard Export Packing

- Specification:Overall Dimensions(mm): 1056x1100x1120,Wt: 1100kg

- Trademark:Hengchang

- Origin:Zhengzhou City, Henan Province, China

- HS Code:8474209000

- Production Capacity:30-50sets,Month

Description

Basic Info.

Model NO. PE200X300 Inlet Size 200X300mm Condition New Material Manganese Steel Warranty Period One Year Excluding Wearing Parts Motor It′s up to You After-Sale Technology Support Engineers Available to Provide Field Services After-Sale Service Supply Life-Long Period Available Spare Parts Supply Life-Long Period Available Installation Engineer′s Guide Available Certificate Ce,ISO9001:2012 Max.Input Size 165mm Transport Package Standard Export Packing Specification Overall Dimensions(mm): 1056x1100x1120/Wt: 1100kg Trademark Hengchang Origin Zhengzhou City, Henan Province, China HS Code 8474209000 Production Capacity 30-50sets/MonthProduct Description

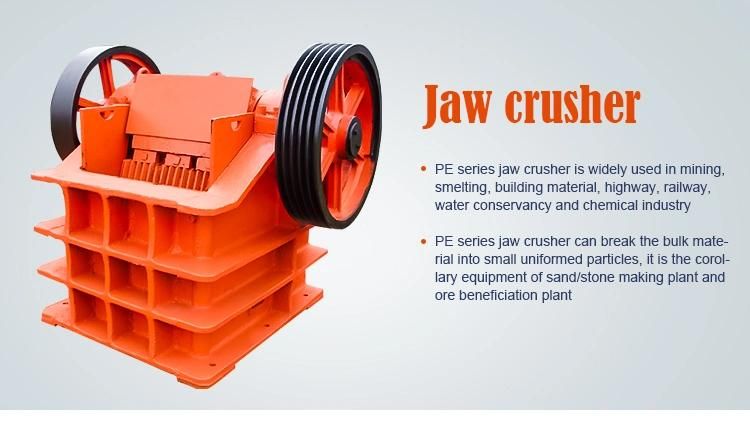

Detailed Information of PE Series Jaw Crusher

| Model | Max. Input Size (mm) | Adjustment Range (mm) | Capacity (t/h) | Shaft Speed (r/min) | Motor Power (kw) | Overall Dimensions (mm) | Weight (kg) |

| PE150*250 | 125 | 10-40 | 1-3 | 285 | 5.5 | 922*745*933 | 750 |

| PE200*300 | 165 | 15-50 | 2-8 | 265 | 7.5 | 1056*1100*1120 | 1100 |

| PE250*400 | 210 | 20-60 | 5-20 | 300 | 15 | 1108*1142*1392 | 2900 |

| PE400*600 | 340 | 40-90 | 25-64 | 280 | 30 | 1700*1732*1653 | 6900 |

| PE500*750 | 425 | 50-100 | 34-68 | 275 | 55 | 2050*1860*2145 | 10500 |

| PE600*900 | 480 | 65-160 | 56-192 | 250 | 75 | 2792*2168*2250 | 17500 |

| PE750*1060 | 630 | 80-140 | 110-242 | 250 | 90 | 4180*2560*3070 | 27000 |

| PE900*1200 | 750 | 100-200 | 158-256 | 250 | 110 | 5200*2900*3500 | 50000 |

| PEX150*750 | 125 | 10-40 | 8-35 | 300 | 15 | 1220*1480*1180 | 3300 |

| PEX250*1000 | 210 | 15-50 | 15-50 | 300 | 30 | 1580*1992*1380 | 7100 |

| PEX250*1200 | 210 | 15-50 | 20-60 | 300 | 45 | 1730*2192*1380 | 8700 |

| PEX300*1300 | 250 | 20-90 | 20-90 | 300 | 75 | 1930*2400*1747 | 11600 |

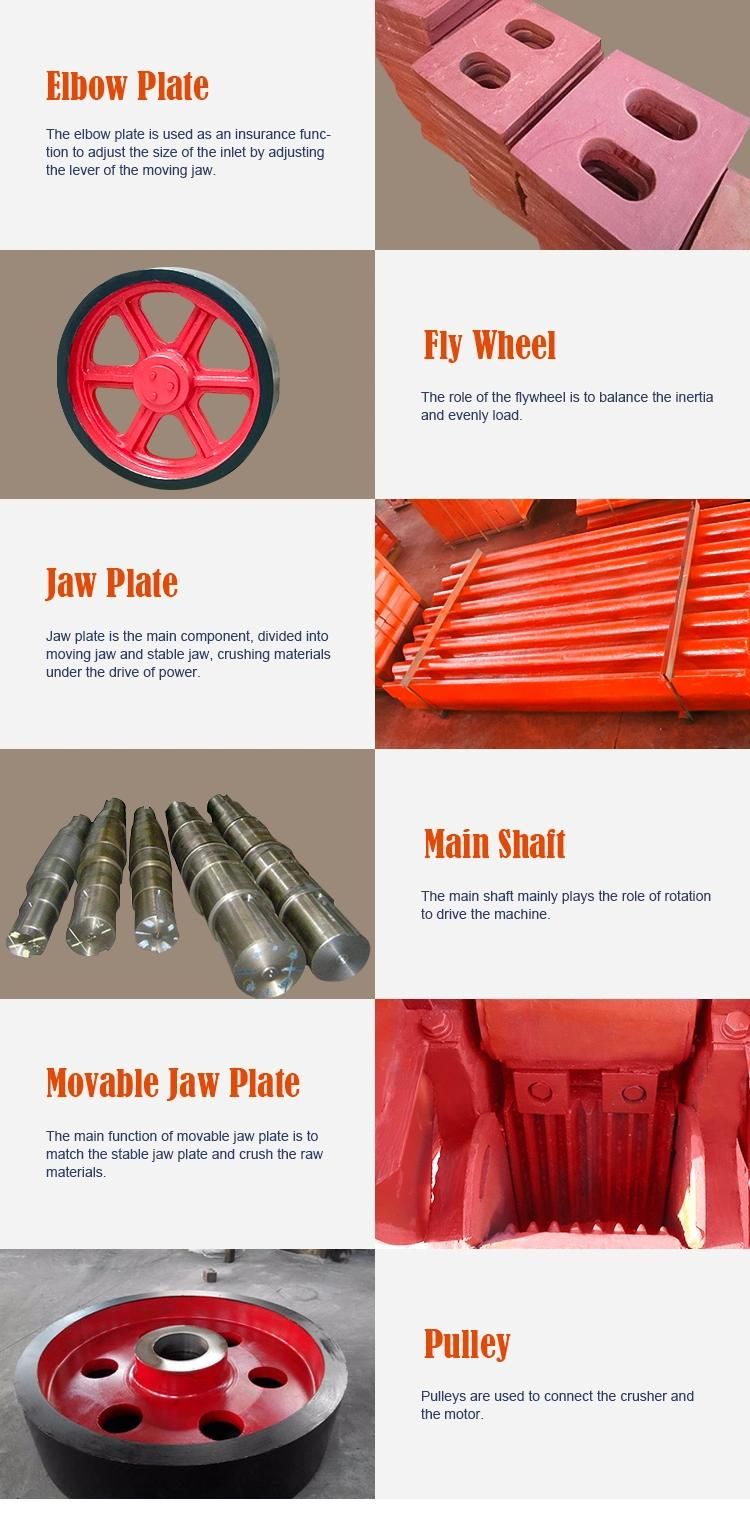

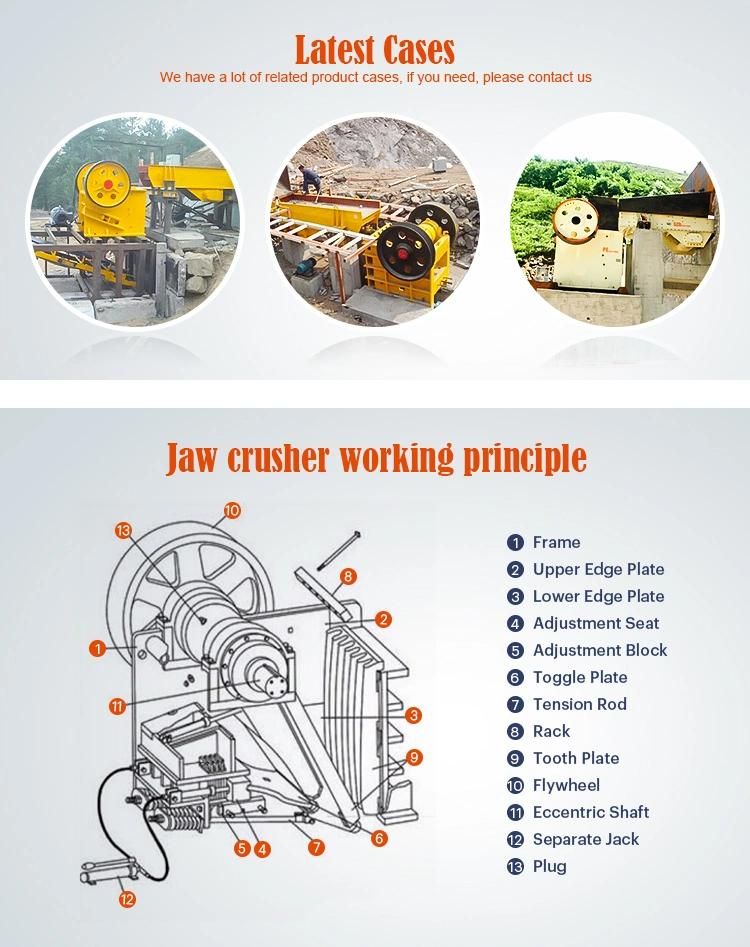

When the jaw crusher is working, the movable jaws make periodic reciprocating motions to the fixed jaws, sometimes approaching and sometimes leaving. When approaching, the material is crushed, split, and impacted between the jaws; when it is removed, the broken material is discharged from the discharge opening by gravity.

In the process of breaking large stones into small stones, the first crusher is usually a "main" crusher. The longest and most solid crusher is a jaw crusher. When feeding the jaw crusher, the material is poured from the top inlet into the crushing chamber containing the rake teeth, and the rake teeth force the material against the wall of the chamber and break it into smaller stones. An eccentric shaft is supported for the movement of the caries, and the eccentric shaft penetrates the frame of the fuselage. Eccentric motion is usually generated by flywheels fixed at both ends of the shaft. Flywheels and eccentrically supported bearings often use spherical roller bearings, which must withstand large shock loads, abrasive sewage, and high temperatures

The advantages of jaw crusher:

1. The crushing force is large, which can crush very hard materials. The vibratory jaw crusher has greater crushing capacity than the conventional crusher. The crushed materials include titanium iron alloy, artificial crystal, silicon calcium alloy, ferrochrome, ferromanganese and the like.

2. The crushing ratio is high and the work efficiency is fast. The jaw crusher is 2-3 times higher than the crusher of the general crusher, and the crushing efficiency is faster.

3, the structure is novel, there will be no blockage. The vibratory jaw crusher adopts a high dynamic impact velocity. By using the principle of inertial transmission, when the material cannot be broken, the mineral will be discharged from the discharge port with the movement of the crusher.

4, can start, stop, overload work under load. The jaw crusher directly drives the eccentric weight by the motor and is not affected by the material in the crushing chamber.

5, the force is fast, with impact characteristics. The vibratory jaw crusher exerts a great degree of steepness on the material, and the force is fast and pulsating.

6. The size of the discharge opening can be adjusted in advance according to the output and other requirements. The grit crusher production particle size requirements depend on the thickness of the material layer and are not affected by the size of the discharge opening.