Energy-Saving Mineral Ore Cone Ball Mill (YMQ series)

Gongyi Hengchang Metallurgical Building Material Equipments Plant- Type:Ball Mill

- Motor Type:AC Motor

- Motor Power:30KW

- Rotationl Speed:23-25r,min

- Application:Mine

- Materials:Gold

Base Info

- Model NO.:YMQ series

- Condition:New

- Warranty:12 Months

- Certificate:ISO CE

- Machine Condition:New

- Color:as Customer Require

- Speed:20.7-39r,Min

- Feed Size:0-25mm

- Output Size:0.075-0.3mm

- Installation:Engineers Guided

- Aftre-Sale Service:We Offer

- Transport Package:Standard Container

- Specification:CE, iso 9001, 2008

- Trademark:Hengchang

- Origin:Gongyi Henan

- HS Code:847410000

- Production Capacity:50 Sets,Month

Description

Basic Info.

Model NO. YMQ series Condition New Warranty 12 Months Certificate ISO CE Machine Condition New Color as Customer Require Speed 20.7-39r/Min Feed Size 0-25mm Output Size 0.075-0.3mm Installation Engineers Guided Aftre-Sale Service We Offer Transport Package Standard Container Specification CE, iso 9001, 2008 Trademark Hengchang Origin Gongyi Henan HS Code 847410000 Production Capacity 50 Sets/MonthProduct Description

Hot Sale Energy-saving Cone Ball MillOur factory's Energy-Saving high efficient cone ball mill adopts automatic self-aligning double row

Centripetal spherical roller bearing, and has the advantages of smaller resistance and remarkable energy-saving effect. In the original cylinder discharging end, we strengthen a conical cylinder system, which increases the effective volume of the ball mill, and make the medium distribution more reasonable. The Energy-Saving Ball Mill are widely used in non-ferrous metal industry, ferrous metal industry, nonmetal mineral industry and chemical industry, and building materials industry for material grinding use.

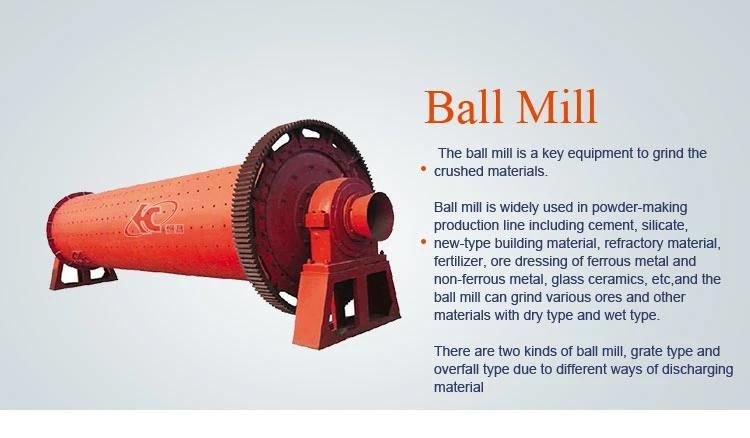

Application of ball mill

The energy saving ball mill is a key equipment for regrinding, it is widely used for the cement, the silicate product, new type building material, fire-proof material, chemical fertilizer, black and non-ferrous metal, glass, ceramics and etc. The ball mill can grind ore or other materials that can be grinded either by wet process or by dry process.

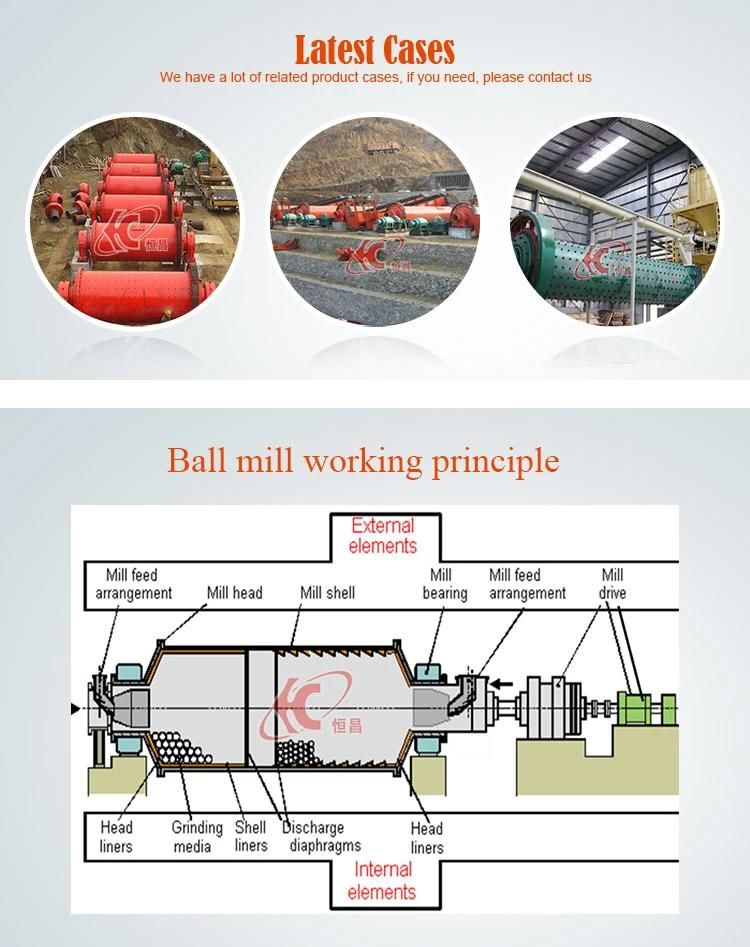

Working principle of ball mill

This ball mill is horizontal type and tubular running device, has two warehouses. This machine is grid type and its outside runs along gear. The material enters spirally and evenly the first warehouse of the milling machine along the input material hollow axis by input material device. In this warehouse, there is a ladder scaleboard or ripple scaleboard, and different specification steel balls are installed on the scaleboard, when the barrel body rotates and then produces centrifugal

Force, at this time, the steel ball is carried to some height and falls to make the material grinding and striking. After grinded coarsely in the first warehouse, the material then enters into the second warehouse for regrinding with the steel ball and scaleboard. In the end, the powder is discharged by output mate board and the end products are complete.

| Model | Rotate Speed ( r/min ) | Max . ball No ( t ) | Feed size ( m ) | Output size ( mm ) | Capacity ( t/h ) | Power ( kw ) | Weight ( t ) |

| YMQ750×1800 | 39 | 1.0 | 0-15 | 0.075-0.3 | 0.3-0.8 | 11 | 3.5 |

| YMQ900×2100 | 37.8 | 1.5 | 0-15 | 0.075-0.3 | 0.8-2.1 | 15 | 5.2 |

| YMQ1200×2800 | 37 | 5.2 | 0-20 | 0.075-0.3 | 1.2-6.2 | 30 | 10 |

| YMQ1500×3500 | 29.7 | 8.0 | 0-25 | 0.075-0.3 | 2.8-9 | 75 | 17 |

| YMQ1500×4500 | 29.7 | 9.5 | 0-25 | 0.075-0.3 | 2.8-10 | 90 | 20 |

| YMQ1830×3600 | 25 | 11.5 | 0-25 | 0.075-0.3 | 5.2-25 | 130 | 28 |

| YMQ1830×4500 | 25 | 16.5 | 0-25 | 0.075-0.3 | 5.2-30 | 155 | 32 |

| YMQ2100×3600 | 24.6 | 17.4 | 0-25 | 0.075-0.3 | 6.5-40 | 180 | 41 |

| YMQ2100×4500 | 24.6 | 22.5 | 0-25 | 0.075-0.3 | 6.5-42 | 210 | 46 |

| YMQ2400×3600 | 22.4 | 23 | 0-25 | 0.075-0.3 | 7.2-92 | 210 | 65 |

| YMQ2400×4500 | 22.4 | 28.5 | 0-25 | 0.075-0.3 | 7.2-95 | 245 | 72 |

| YMQ2700×3600 | 20.7 | 40 | 0-25 | 0.075-0.3 | 12-145 | 320 | 80 |

| YMQ2700×4500 | 20.7 | 50 | 0-25 | 0.075-0.3 | 12-155 | 380 | 90 |