Raymond Grinding Mill Carbon Black Processing Machine for Sale

Qingdao Longyuan Baihong Machinery Equipment Co., Ltd.- Type:Water

- Motor Type:AC Motor

- Motor Power:15KW

- Rotationl Speed:20-22r,min

- Application:Carbon Black

- Materials:Carbon Black

Base Info

- Condition:New

- Installation Nmethod:Vertical

- Operation Ntype:Automatic

- Dust Collecting Method:Wet

- Medium Material:Water

- Transport Package:Pallet Package

- Specification:LYBH-CB01

- Trademark:Long Yuan Bai Hong

- Origin:Qingdao, China

- HS Code:8421399000

- Production Capacity:60

Description

Basic Info.

Condition New Installation Nmethod Vertical Operation Ntype Automatic Dust Collecting Method Wet Medium Material Water Transport Package Pallet Package Specification LYBH-CB01 Trademark Long Yuan Bai Hong Origin Qingdao, China HS Code 8421399000 Production Capacity 60Product Description

Company Profile Our Qingdao Longyuan Baihong Machinery Equipment Co., Ltd is a big manufacturer for Pyrolysis Equipment for 22 years in China. We located at Qingdao-----a beautiful and Industry developed city.We established in year 1997, our main products are environment pyroloysis equipment.The company has passed ISO9001 certification, CE certification and SGS international third party certification.To the overall design, production and manufacturing, installation and commissioning, technical training, after-sales service in the whole industrial chain operation of high-tech enterprises.Product details

Our Qingdao Longyuan Baihong Machinery Equipment Co., Ltd is a big manufacturer for Pyrolysis Equipment for 22 years in China. We located at Qingdao-----a beautiful and Industry developed city.We established in year 1997, our main products are environment pyroloysis equipment.The company has passed ISO9001 certification, CE certification and SGS international third party certification.To the overall design, production and manufacturing, installation and commissioning, technical training, after-sales service in the whole industrial chain operation of high-tech enterprises.Product detailsBrief description of process flow

After magnetic separation and crushing, the raw carbon black generated by waste tire pyrolysis is sent to the transition bin.Mix the water with the adhesive in a proportionally proportioned mixing pot.The carbon black in the transition bin and the liquid in the batching tank are mixed evenly in a certain proportion and then into the granulator for wet granulation.After the completion of granulation of carbon black into the dryer for full drying after sieving.The oversized particles and fine powder are broken as unqualified particles through the particle crusher and then granulated again.The particles with moderate particle size are transported to the packaging machine for storage as qualified products.

Technical advantages

1. Industrial continuous stable operation for a long period

The production line adopts such core technologies as heat and gas tightness to realize continuous automatic feeding, oil discharging and body products during the whole cracking process, which truly realizes continuous and stable industrial operation with simple and reasonable process flow and greatly improves production capacity and treatment efficiency.

2. Coking free and thermal dispersion technology

The proprietary non-coking and thermal dispersion technology can effectively reduce the cracking temperature, evenly heat, fully and completely crack, improve the yield and quality of liquid oil products, realize long time safe and stable operation of the production line, and greatly extend the service life of the equipment.

3. Energy conservation and emission reduction

Using the technology of gas purification and waste heat recycling, the gas generated in the cracking process is used as fuel in the heating unit after purification treatment to provide the heat required for equipment operation and reduce fuel consumption and flue gas emission.

4.Intelligent automation

The whole set of equipment adopts PLC/DCS automatic intelligent control system, which can monitor, collect, display, calculate and deal with each single device and process control point in real time, and issue corresponding instructions, automatically correct deviation and automatically alarm, so as to truly realize intelligent and safe operation.

5. Environmental standards

The equipment adopts standard burners and heating devices to significantly reduce the production of harmful gas, and the flue gas after multi-stage purification and comprehensive treatment reaches the emission standard. The emission index is superior to the current emission standard of China, EEA and EPA.

Our Advantages1.Outstanding Features:a. The reactor need preheat at the first when the machine starts producing.

Our Advantages1.Outstanding Features:a. The reactor need preheat at the first when the machine starts producing.b. 24h continuous working for 20-30 days without any stops.

c. No need fuels, sync gas is recycled during the operation.

d. Large daily capacity:20-25T/D;25-30T/D

e. New desing of vertical condensers. Good oil quality with high profit.

f. Low requirement on the raw materials. 2. Security:

a: Adopting automatic submerged-arc welding technology

b: All of the welding will be detected by the ultrasonic nondestructive testing method to ensure the welding quality and the

welding shape.c: Adopting manufacture process controlling system on the quality, every manufacture process, manufacture date, etc.d: Equipped with anti-explosion device, safety valves, emergency valves, pressure and temperature meters, as well as the alarming

system.3. Environmental-friendly:

a: Emission Standard: Adopting special gas scrubbers to remove acid gas and dust from smokeb: Smell during operation: Fully enclosed during the operationc: Water pollution: No pollution at all.d: Solid pollution: the solid after pyrolysis is the crude carbon black and steel wires which can be deep-processed or sold

directly with its value.

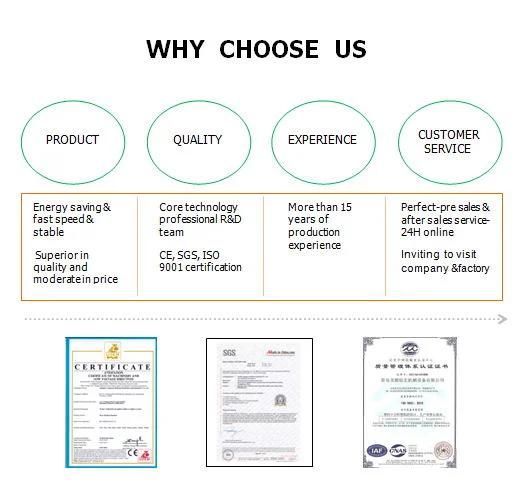

Why Choose Us

Our service1.Quality warranty period: One year warranty for the main reactor of pyrolysis machines

and lifetime maintenance for complete set of machines.

2.Our company sends engineers for installation and commissioning in buyer's site including the training of skills of buyer's

workers on operation, maintenance, etc.3. Supply layout according to buyer's workshop and land, civil works information, operation manuals, etc. to the buyer.4. For the damage caused by the users, our company provides the parts and accessories with cost price.5. Our factory supplies the wearing parts with the cost price to clients.