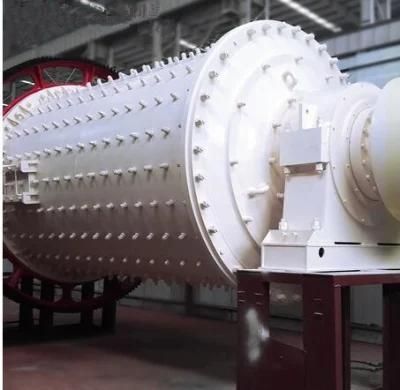

Ball Mill for Mine Beneficiation Plant

Zhengzhou Hengxing Heavy Equipment Co., Ltd.- Type:Ball Mill

- Motor Type:AC Motor

- Motor Power:18.5KW

- Rotationl Speed:21-23r,min

- Application:Mine

- Materials:Mineral Ore, Rock, Stone, Sand, Quartz, Limestone

Base Info

- Model NO.:2400*3000mm

- Condition:New

- Capacity(T/H):1-50tph

- Certificate:ISO9001-2008

- Input Size:25mm and Down

- Output Size:0-400mesh(Adjustable)

- Bearing:Roller or Bush Bearing in Choice

- Discharge System:Overflow or Grate Type in Choice

- Spare Parts:Supply for Whole Life

- Warranty:1 Year Apart From Wearing Parts

- Color:on Requst

- After Sales Service:Offer for Whole Using Life

- Transport Package:Standard Container

- Specification:International standard

- Trademark:hengxing

- Origin:Henan, China

- Production Capacity:50tph

Description

Basic Info.

Model NO. 2400*3000mm Condition New Capacity(T/H) 1-50tph Certificate ISO9001-2008 Input Size 25mm and Down Output Size 0-400mesh(Adjustable) Bearing Roller or Bush Bearing in Choice Discharge System Overflow or Grate Type in Choice Spare Parts Supply for Whole Life Warranty 1 Year Apart From Wearing Parts Color on Requst After Sales Service Offer for Whole Using Life Transport Package Standard Container Specification International standard Trademark hengxing Origin Henan, China Production Capacity 50tphProduct Description

Ball Mill For Mine Beneficiation Plant Ball mill is an efficient tool for grinding many materials into fine powder. The Ball Mill is used to grind many kinds of mine and other materials, or to select the mine. It is widely used in building material, chemical industry, etc. There are two ways of grinding: The dry way and the wet way. It can be divided into tabular type and flowing type according to different expelling mine.Applied materials: iron ore, copper ore, gold ore,cement, lime, bauxite, calcite, barite, gypsum, quartz, slag, etc

Hot Sale Ball Mill Types

1. Ball Mill is one of the most popular and best-selling products. Ball mill can be divided into dry type ball mill and wet type lattice ball mill.

2. There are three different types. Small, Medium and Large-sized Models, Let our technical people choose one reasonable for you.

3. The hot-sale models are including 600×700, 900×1200, 1500×1800, 1800×2000, 3200×4600,

To use the Ball Mill, the material to be ground is loaded into the Neoprene barrel that contains grinding media. As the barrel rotates, the material is crushed between the individual pieces of grinding media that mix and crush the product into fine powder over a period of several hours.

Quite simply, the longer the Ball Mill runs, the finer the powder will be. Ultimate particle size depends entirely on how hard the material you're grinding is, and the time how long the Ball Mill runs. Our Ball Mills have been used to grind glass, powder food products, create custom varnishes, make ceramic glaze, powder various chemicals, etc.

ball mill main technical parameters:

ball mill main technical parameters:| Model | shaft rotation speed(r/min) | Ball load(t) | Feeding size(mm) | Discharging size(mm) | Capacity(t/h) | Power(KW) | Weight(T) |

| Φ 900 × 1800 | 38 | 1.5 | ≤ 20 | 0.075 -0.89 | 0.65 -2 | 18.5 | 3.6 |

| Φ 900 × 2100 | 38 | 1.3-1.4 | ≤ 15 | 0.075 -0.83 | 0.7 -3.5 | 18.5 | 3.9 |

| Φ 900 × 3000 | 38 | 2.7 | ≤ 20 | 0.075 -0.89 | 1.1-3.5 | 22 | 4.5 |

| Φ 1200 × 2400 | 32 | 3.8 | ≤ 25 | 0.0745-0.6 | 1.5-4.8 | 30 | 11.5 |

| Φ 1200 × 2800 | 32 | 3.3-3.5 | ≤ 25 | 0.0745-0.6 | 2-6 | 30 | 13 |

| Φ 1200 × 4500 | 32 | 7 | ≤ 25 | 0.074 -0.4 | 1.6-5.8 | 45 | 13.8 |

| Φ 1500 × 3000 | 27 | 8 | ≤ 25 | 0.074 -0.4 | 2-5 | 75 | 17 |

| Φ 1500 × 3500 | 27 | 6.75 -6.4 | ≤ 25 | 0.075 -0.4 | 3-7 | 75 | 17.5 |

| Φ 1500 × 4500 | 27 | 14 | ≤ 25 | 0.074 -0.4 | 3.5-12 | 110 | 21 |

| Φ 1500 × 5700 | 27 | 15 | ≤ 25 | 0.074 -0.4 | 3.5-8 | 115 | 24.7 |

| Φ 1830 × 3000 | 24 | 18 | ≤ 25 | 0.074 -0.4 | 4-10 | 130 | 28 |

| Φ 1800 × 3600 | 24 | 10.6 -11.35 | ≤ 25 | 0.075 -0.4 | 5-22 | 130 | 33.5 |

| Φ 1830 × 7000 | 24 | 25 | ≤ 25 | 0.074 -0.4 | 7.5-17 | 210 | 36 |

| Φ 2100 × 3600 | 22 | 14-15.2 | ≤ 25 | 0.075 -0.4 | 15-36 | 370 | 46.8 |

| Φ 2200 × 5500 | 21 | 30 | ≤ 25 | 0.074 -0.4 | 10-20 | 210 | 48.5 |

| Φ 2200 × 6500 | 21 | 31 | ≤ 25 | 0.074 -0.4 | 14-26 | 380 | 52.8 |

| Φ 2200 × 7500 | 21 | 33 | ≤ 25 | 0.074 -0.4 | 16-29 | 380 | 56 |

| Φ 2400 × 3000 | 20.6 | 15.5 -16.6 | ≤ 25 | 0.075 -0.4 | 22-24 | 245 | 59 |

| Φ 2400 × 4500 | 21 | 30 | ≤ 25 | 0.074 -0.4 | 8.5-60 | 380 | 65 |

| Φ 2700 × 3600 | 20.6 | 39 | ≤ 25 | 0.074 -0.4 | 12-70 | 400 | 91.3 |

| Φ 2700 × 4000 | 20.7 | 40 | ≤ 25 | 0.074 -0.4 | 12-80 | 400 | 94 |

| Φ 2700 × 4500 | 20.7 | 48 | ≤ 25 | 0.074 -0.4 | 12-90 | 430 | 102 |

| Φ 3200 × 4500 | 18 | 65 | ≤ 25 | 0.075 -0.4 | according to the technics | 800 | 137 |

Significant Advantages of Ball Mill

Energy Saving and Less Power Consumption

The matching of the drive and the grinding media can greatly lower the power consumption.

The Flexible Design of the Discharging Port

The customers can decide whether the iron removing device is required or not according to their demand.

The Bigger Feeding Size

The reasonable design on the feeding port can increase the feeding output.

Leave your contact information and project information in the message box at the bottom of the page, such as materials, capacity, or other detailed information. Our engineers will contact you in time to serve you.

SaraMobile phone: 0086 137 8347 1727