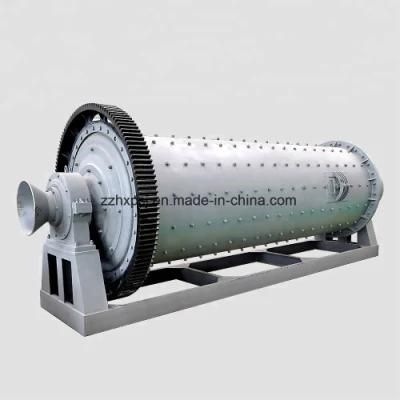

3.2X4.5m Wet Grinding Ball Mill for Copper Ore

Zhengzhou Hengxing Heavy Equipment Co., Ltd.- Type:Ball Mill

- Motor Type:AC Motor

- Motor Power:380kw

- Rotationl Speed:16-18r,min

- Application:Mine

- Materials:Copper Ore ,Gold ,etc

Base Info

- Model NO.:3.2 x4.5m

- Condition:New

- Input Size:25mm and Down

- Color:on Requst

- Spare Parts:Supply for Whole Life

- Bearing:Roller or Bush Bearing in Choice

- Warranty:1 Year Apart From Wearing Parts

- Capacity(T/H):1-50tph

- Output Size:0-400mesh(Adjustable)

- Discharge System:Overflow or Grate Type in Choice

- Mining Object:Metallic and Non-Metallic Ore Excavator

- Transport Package:Standard Container

- Specification:International standard

- Trademark:hengxing

- Origin:Henan, China

- Production Capacity:5-100t,H

Description

Basic Info.

Model NO. 3.2 x4.5m Condition New Input Size 25mm and Down Color on Requst Spare Parts Supply for Whole Life Bearing Roller or Bush Bearing in Choice Warranty 1 Year Apart From Wearing Parts Capacity(T/H) 1-50tph Output Size 0-400mesh(Adjustable) Discharge System Overflow or Grate Type in Choice Mining Object Metallic and Non-Metallic Ore Excavator Transport Package Standard Container Specification International standard Trademark hengxing Origin Henan, China Production Capacity 5-100t/HProduct Description

3.2x4.5m Wet Grinding Ball Mill for Copper OreBall Mill Application

The ball mill grinds material by rotating a cylinder with steel grinding balls, causing the balls to fall back into the cylinder and onto the material to the ground. The rotation is usually between 4 to 20 revelutions per minute, depending upon the diameter of the mill. The larger the diameter, the slower the rotation. If the periphal speed of the mill is too great, it begins to act like a centrifuge and the balls do not fall back, but stay on the perimeter of the mill. The point where the mill becomes a centrifuge is called the "Critical Speed", and ball mills usually operate at 65% to 75% ofthe critical speed.

Characteristics of Ball mill:

1) It is an efficient tool for grinding many materials into the power.

2) The ball mill is used to grind many kinds of mine and other materials, or to select the mine

3) Ball mill is widely used in building material, and chemical indurstry.

4) There are two ways to grind: The dry way and the wet way

5) Ball mill can be divided into tabular type and flowing type according to different expelling mine

6) To use the ball mill, the material to be ground is loaded into the neoprene barrel that contains grinding media

7) As the barrel rotates, the material is crushed between the individual pieces of grinding media that mix and Crush the product into fine Power over a period of several hours.

8) The longer the ball mills runs, the finer the powder will be

9) Ultimate particle size depends entirely on how hard the material you're grinding is, and theTime how long the ball mill runs

10) Our ball mills have used to grind glass, powder food products, create custom varnishes, make ceramic glaze, powder various chemicals

Wet grinding ball mill main technical specifications :

| Model | Rotationna speed r/min | Ball load t | Feeding size mm | Output size mm | Capacity t/h | Power kw | Weight t |

| 900× 1800 | 36-38 | 1.5 | ≤ 20 | 0.075-0.89 | 0.65-2 | 18.5 | 4.6 |

| 900× 3000 | 36 | 2.7 | ≤ 20 | 0.075-0.89 | 1.1-3.5 | 22 | 5.6 |

| 1200× 2400 | 36 | 3 | ≤ 25 | 0.075-0.6 | 1.5-4.8 | 30 | 12 |

| 1200× 3000 | 36 | 3.5 | ≤ 25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 |

| 1200× 4500 | 32.4 | 5 | ≤ 25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 |

| 1500× 3000 | 29.7 | 7.5 | ≤ 25 | 0.074-0.4 | 2-5 | 75 | 15.6 |

| 1500× 4500 | 27 | 11 | ≤ 25 | 0.074-0.4 | 3-6 | 90 | 21 |

| 1500× 5700 | 28 | 12 | ≤ 25 | 0.074-0.4 | 3.5-6 | 130 | 24.7 |

| 1830× 3000 | 25.4 | 11 | ≤ 25 | 0.074-0.4 | 4-10 | 130 | 28 |

| 1830× 4500 | 25.4 | 15 | ≤ 25 | 0.074-0.4 | 4.5-12 | 155 | 32 |

| 1830× 6400 | 24.1 | 21 | ≤ 25 | 0.074-0.4 | 6.5-15 | 210 | 34 |

| 1830× 7000 | 24.1 | 23 | ≤ 25 | 0.074-0.4 | 7.5-17 | 245 | 36 |

| 2100× 3000 | 23.7 | 15 | ≤ 25 | 0.074-0.4 | 6.5-36 | 210 | 34 |

| 2100× 4500 | 23.7 | 24 | ≤ 25 | 0.074-0.4 | 8-43 | 245 | 42 |

| 2100× 7000 | 23.7 | 26 | ≤ 25 | 0.074-0.4 | 8-48 | 280 | 50 |

| 2200× 4500 | 21.5 | 27 | ≤ 25 | 0.074-0.4 | 9-45 | 280 | 48.5 |

Wet grinding ball mill production workshop :

Ball mill site :

You are welcome to our company for visiting and business cooperation. We will provide you the best services and most favorable price. For more introduction, please contact with me !