Conveyor Idler Set Conveyor Roller Trough Roller Carrier Roller

Shandong Mingyang Conveyor Equipment Co., Ltd.- Type:Gravity Conveyor

- Structure:Roller Conveyor

- Material:Carbon Steel

- Material Feature:Fire Resistant

- Certification:ISO9001:2008, ISO9001:2000

- Energy Saving:Energy Saving

Base Info

- Warranty:1 Year

- Color:Multi Color

- Customized:Customized

- Condition:New

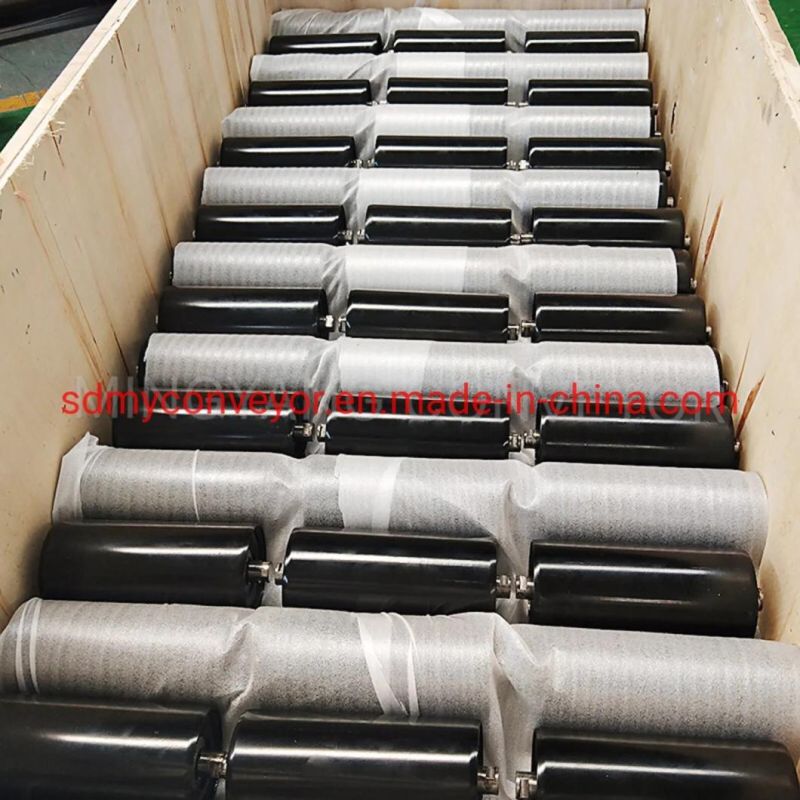

- Transport Package:Plywood Box

- Origin:China

- HS Code:843139

- Production Capacity:1800000

Description

Basic Info.

Warranty 1 Year Color Multi Color Customized Customized Condition New Transport Package Plywood Box Origin China HS Code 843139 Production Capacity 1800000Product Description

Carrier Roller are used to support the conveyor belt and are installed on the groove-shape frame,Groove-shape forward inclined idler frames and transition idler frames.

Roller is an important part of belt conveyor. It has many kinds and large quantity, and can support the weight of conveyor belt and materials. It accounts for 35% of the total cost of a belt conveyor and produces more than 70% resistance, so the quality of Roller is particularly important. They are made of steel and plastic. The Roller must operate flexibly and reliably. Reduce the friction between conveyor belt and Roller. Although Roller is a small part in belt conveyor and its structure is not complex, it is not easy to manufacture high-quality Roller.

The criteria for judging the quality of Roller are as follows: radial runout of Roller; Flexibility of Roller; Axial displacement

1. According to the material, it is divided into rubber Roller, ceramic Roller, nylon Roller and insulating Roller.

2. There are mainly grooved Roller groups, all kinds of parallel Roller groups, all kinds of self-aligning Roller groups and all kinds of buffer Roller groups.

(1) Grooved Rollers include ordinary Rollers, forward inclined Rollers, quick change bearing Rollers, hanging Rollers, three chain Rollers, reversible Rollers, variable groove angle Rollers, transition Rollers, v-Rollers, etc;

(2) Parallel Rollers include ordinary Rollers, comb Rollers, forward inclined Rollers, steel rubber Rollers, spiral Rollers, etc;

(3) Self aligning Rollers include universal, friction reversible Rollers, strong Rollers, cone Rollers, spiral Rollers, combined Rollers, etc;

(4) Buffer Rollers include spring plate Rollers, buffer ring Rollers, strong buffer Rollers, adjustable elastic Rollers, hanging Rollers, etc;