China Professional Manufacturer Gravity Separation Equipment Coltan Tin Ore Processing ...

Jiangxi Province County Mining Machinery Factory- Type:Gravity Separator

- Voltage:Could Be Customized

- Weight:Depend on Order

- Material:Casting Steel

- Material Feature:Heat Resistant

- Certification:ISO9001:2008, ISO9001:2000, CE

Base Info

- Model NO.:coltan tin tungsten ore processing plant

- Energy Saving:Energy Saving

- Warranty:1 Year

- Color:Depend on Production

- Customized:Customized

- Condition:New

- After-sales Service:Provided

- Processing Capacity:1-300 T,H Provided

- Application Area:Tantalum-Niobium Ore, Tin Ore, Tungsten Ore

- Flowchart:Provided Before Order

- Plant Layout Drawing:Provided After Order

- Auxiliary Equipment for Installation:Provided

- Installation Guidance:Provided(If Necessary,We Will Send Engineer)

- Full Line Equipment for Project:Provided

- Mobile Plant:Provided

- Mining Solution:Provided

- Driving Way for Machine:Diesel Engine or Electric Motor Drive Available

- Payment Term:40%Tt Prepaid,60% Tt After

- Price Term:Accept EXW,Fob,CIF,CFR

- Delivery Term:30 Days After Receive Full Payment

- Inspection Equipment Before Delivery:Support

- Visit Factory:Support

- Transport Package:Shipping by 20gp or 40hq or Flat Container

- Trademark:JXSC or customized

- Origin:Ganzhou, Jiangxi

- Production Capacity:200sets,Month

Description

Basic Info.

Model NO. coltan tin tungsten ore processing plant Energy Saving Energy Saving Warranty 1 Year Color Depend on Production Customized Customized Condition New After-sales Service Provided Processing Capacity 1-300 T/H Provided Application Area Tantalum-Niobium Ore, Tin Ore, Tungsten Ore Flowchart Provided Before Order Plant Layout Drawing Provided After Order Auxiliary Equipment for Installation Provided Installation Guidance Provided(If Necessary,We Will Send Engineer) Full Line Equipment for Project Provided Mobile Plant Provided Mining Solution Provided Driving Way for Machine Diesel Engine or Electric Motor Drive Available Payment Term 40%Tt Prepaid,60% Tt After Price Term Accept EXW,Fob,CIF,CFR Delivery Term 30 Days After Receive Full Payment Inspection Equipment Before Delivery Support Visit Factory Support Transport Package Shipping by 20gp or 40hq or Flat Container Trademark JXSC or customized Origin Ganzhou, Jiangxi Production Capacity 200sets/MonthProduct Description

Tungsten / Tin / Coltan Processing Plant

Regular Steps For Processing Alluvial Tungsten/Tin/Coltan Ore

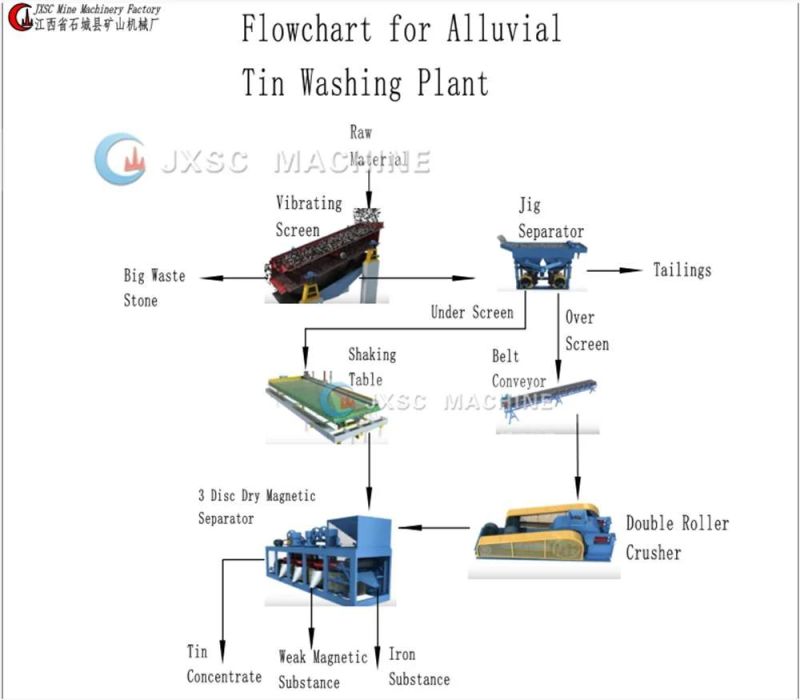

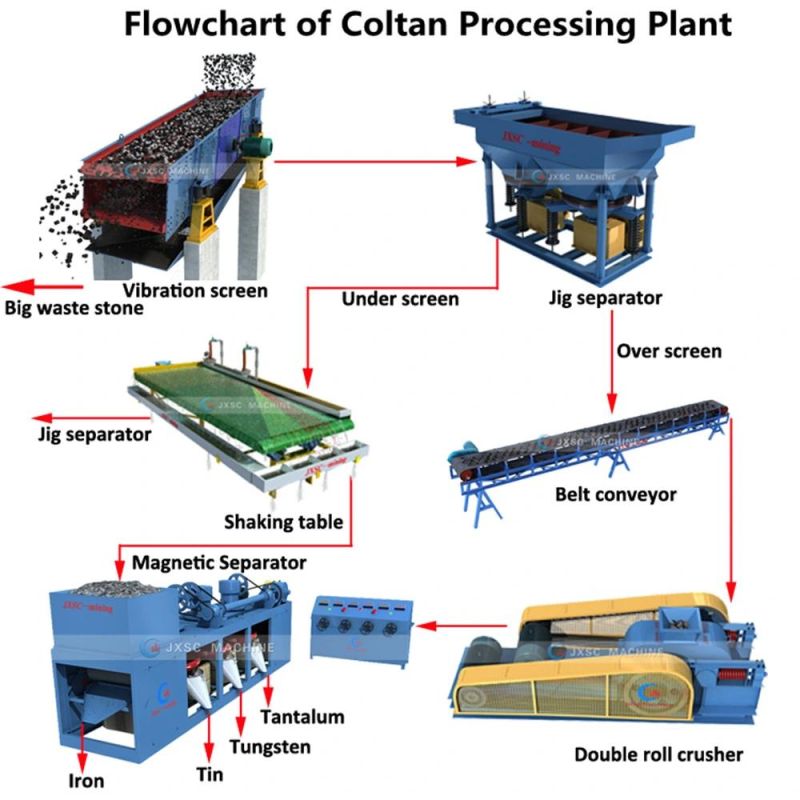

Stage 1: Washing--trommel scrubber or trommel screen will be used in this step. If raw ore contain much sticky clay or heavy clay,have to use trommel scrubber. If raw ore dont contain sticky clay,just alluvial only or just sand only, we can use trommel screen. Stage 2: Classification size--Vibrating screen or high frequency vibrating screen will be used at this step. Stage 3: Gravity concentration--Jig separator,shaking table and spiral chute will be used in this step. Stage 4: Magnetic Separation--three disc magnetic separator or wet drum magnetic separator will be used at this step.

Stage 5: Drying-- dryer will be used at this step. If small scale mining project, no need use dryer, just natural drying in the sun.

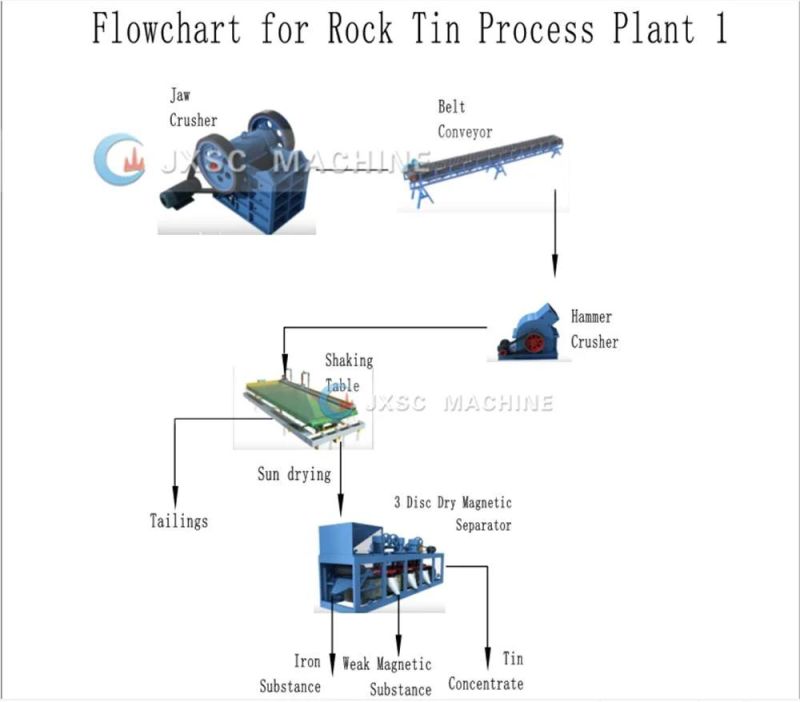

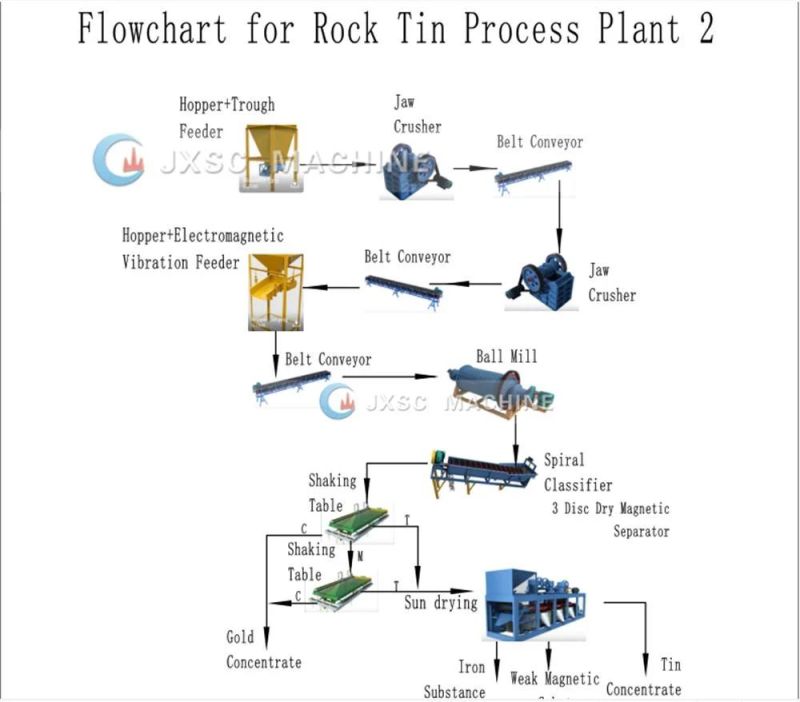

If the raw ore is hard rock type, need add crushing stage and milling stage. After the rocks crushed and milled to fine small size,then gravty concentration and magnetic separation.

Most Useful Mining Equipment For Tungsten/Tin/Coltan Ore

Regular Flowchart For Tungsten/Tin/Coltan Ore

(1) Flowchart for Alluvial Tin Ore

(2)Flowchart For Rock Tin Ore (Cassiterite)

(3)Flowchart For Coltan/Tungsten Ore

Project Cases

100TPH Alluvial Coltan Processing Plant For Nigerian Project

Project date: 2018Processing capacity: 100 tons per hourThe complete line equipment include: vibrating feeder+trommel scrubber+jig separator+shaking table+three disc magnetic separator+hammer crusher+slurry pump+water pump

Site picture:

Loading picture:

100TPH Tin Ore Processing Plant For Uganda Project JXSC factory designed the efficient flowchart according to customer's tin ore information and supplied this complete line equipment.

Site picture:

Packing&Shipping

1. Spare parts would be packed in wooden boxes to avoid broken.

2. Whole machines are fixed and loaded in container directly.

3. Shipped by sea with 20ft or 40ft container.

Our company

JXSC Factory

JXSC Mining Machinery Factory is an experienced supplier of complete set mining equipments, professional at providing complete set processing equipments for Gold ore /Tin ore /Tungsten ore /Iron ore / Diamond/ Coltan ore / Silica sand / Zircon sand/ Black sand/Chrome ore, ect. As well as complete set small lab mining machines.

Our Core Advantages as below :

1.+30 years history FACTORY at mining machinery

2.Provide engineer team after sales service

3.Provide Complete set mineral processing plant

4.Provide Sample testing service in factory lab for free

5.Provide professional Mining Solution Consulting

JXSC Main product including:

trommel screen, trommel scrubber, shaking table, spiral chute separator, jig machine, centrifugal concentrator, sluice box, vibration screen, melting furnace, jaw crusher, hammer crusher, ball mill, flotation machine, spiral classifier. water pump,slurry pump,gravel pump, crushing machine,as well complete set small laboratory mining equipments

Our service

Pre-Sales Service

*Inquiry and consulting support*Ore sample testing support

*View our Factory

*Design Flowchart

After-Sales Service

* Training how to instal the machine, training how to use the machine.* 1 year warranty

* Engineers available to service machinery overseas.