Professional Design CIL CIP Gold Mining Line Leaching Plant with 5-50tph

Zhengzhou Effort Trading Co., Ltd.- Type:Flotation Separator

- Voltage:380V

- Weight:8T

- Material:Carbon Steel

- Material Feature:Heat Resistant

- Energy Saving:Energy Saving

Base Info

- Model NO.:5-50 TPH

- Warranty:2 Years

- Color:Multi Color

- Customized:Customized

- Condition:New

- After-sales Service:Installation

- Transport Package:Standard Export Package

- Specification:2-50 TPH

- Trademark:Effort

- Origin:Henan, China (Mainland)

- Production Capacity:50set,Month as Per Order Quantity

Description

Basic Info.

Model NO. 5-50 TPH Warranty 2 Years Color Multi Color Customized Customized Condition New After-sales Service Installation Transport Package Standard Export Package Specification 2-50 TPH Trademark Effort Origin Henan, China (Mainland) Production Capacity 50set/Month as Per Order QuantityProduct Description

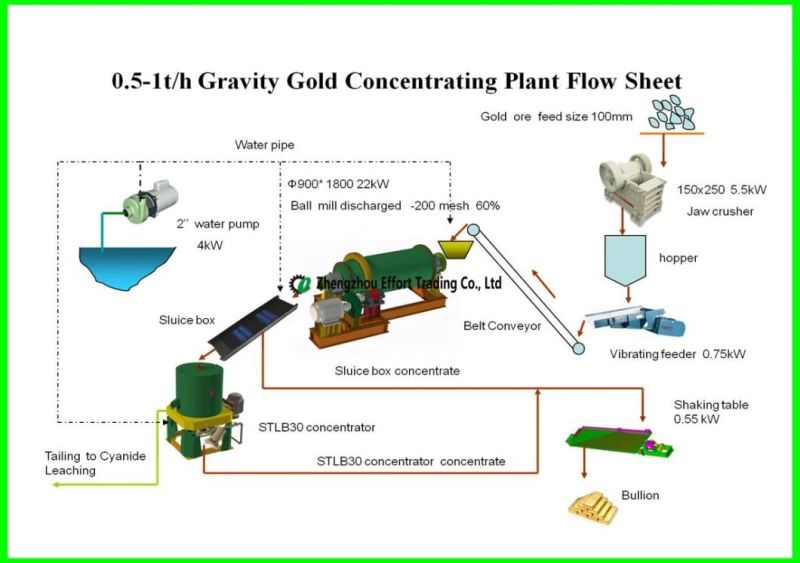

Professional Design CIL CIP Gold Mining Line Leaching Plant With 5-50TPHOur engineers have more than 20 years' experience for gold ore mining so we can provide different project plan based on different kind gold ore

The content of gold in the raw ore is extremely low.

In order to extract the gold, the ore needs to be crushed and ground and the beneficiation method is used to pre-enrich or separate the gold from the ore.

The most widely used in gold beneficiation is gravity separation and flotation.

The gravity separation method plays a very important role in the production of placer gold.

Flotation is a widely used beneficiation method for rock gold mines.

At present, about 80% of rock gold mines in China With this method of gold selection, the level of beneficiation technology and equipment has been greatly improved.

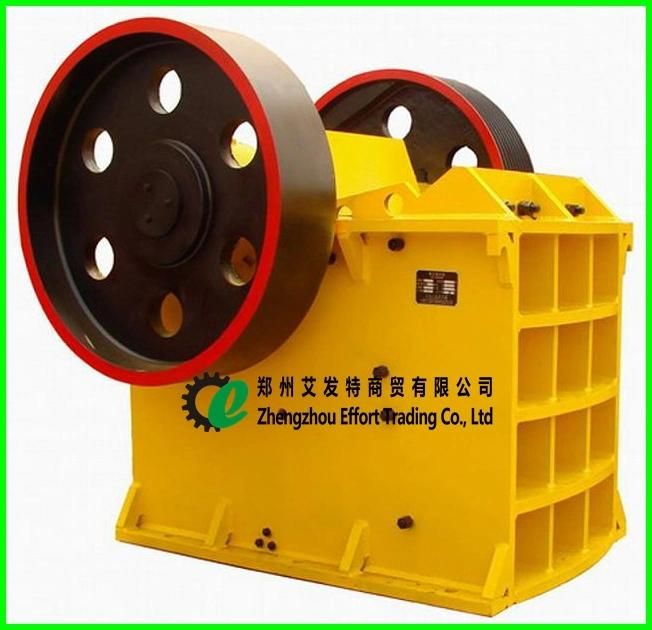

(1) Crushing and grinding According to surveys, China's gold processing plants mostly use jaw crushers for coarse crushing, standard cone crushers, and fine crushers for short-head cone crushers and counter-roll crushers.

Most of the small and medium-sized gold dressing plants use two sections and one closed-circuit crushing ore, and the large-scale gold dressing plants use three sections and one closed-circuit crushing process.

In order to increase the ore dressing production capacity and excavate the potential of equipment, the crushing process has been modified to increase the utilization factor of the mill.

The main measure adopted is to implement more crushing and less milling to reduce the size of the ore into the mill.

(2) re-election Re-selection is widely used in rock gold mines, mostly as an auxiliary process, recovering coarse-grained gold in the grinding circuit, creating favorable conditions for flotation and cyanidation processes, improving ore dressing indicators, increasing the total recovery rate of gold, and increasing production.

And reducing costs has played a positive role.