High Intensity 1.4t Wet Magnetic Electrostatic Separator Vertical Ring Electro Magnetic ...

Weifang Guote Mining Equipment Co., Ltd.- Type:Magnetic Separator

- Voltage:220V

- Weight:Depend on Different Models

- Material:Carbon Steel

- Material Feature:Heat Resistant

- Certification:ISO9001:2008, CE

Base Info

- Model NO.:GTLH

- Energy Saving:Energy Saving

- Warranty:1 Year

- Color:Multi Color

- Customized:Customized

- Condition:New

- Rated Background Magnetic Field:1.4t (1.8t)

- Dielectric Induced Magnetic Field:2.1t (3.6t)

- Usage:Mining Separatoion

- Installation:Engineer Guide

- Feeding Size:<1.2mm

- Function:Deironing Purification

- Slurry Density(%):10-40

- Ring Speed(R/Min):3

- Pulsion Stroke:0-30

- Excitation Voltage:0-514(700)

- Transport Package:Standard Sea Worthy Packing for Drum Type Wet Magn

- Specification:depend on different models

- Trademark:Guote

- Origin:Weifang

- HS Code:8474100000

- Production Capacity:50sets,Month

Description

Basic Info.

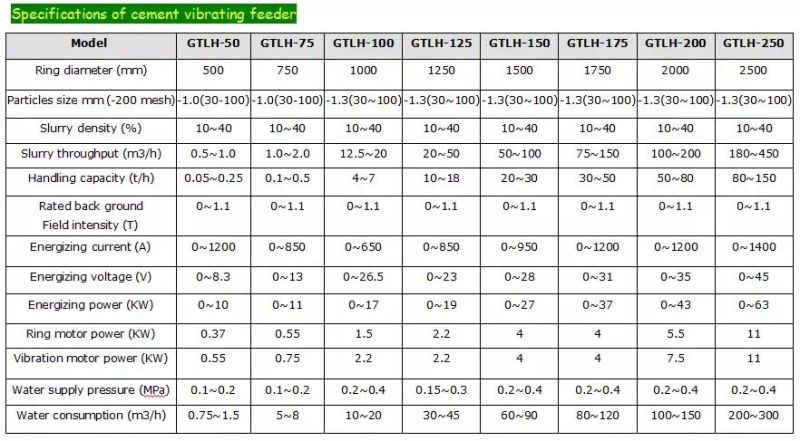

Model NO. GTLH Energy Saving Energy Saving Warranty 1 Year Color Multi Color Customized Customized Condition New Rated Background Magnetic Field 1.4t (1.8t) Dielectric Induced Magnetic Field 2.1t (3.6t) Usage Mining Separatoion Installation Engineer Guide Feeding Size <1.2mm Function Deironing Purification Slurry Density(%) 10-40 Ring Speed(R/Min) 3 Pulsion Stroke 0-30 Excitation Voltage 0-514(700) Transport Package Standard Sea Worthy Packing for Drum Type Wet Magn Specification depend on different models Trademark Guote Origin Weifang HS Code 8474100000 Production Capacity 50sets/MonthProduct Description

High intensity 1.4T wet magnetic electrostatic separator vertical ring electro magnetic separator

Product Introduction:

The high intensity magnetic separator with most advanced technology and best performance in the worldwide. Whole equipment have swivel vertical rotation and back flush mineral ores functions, following with high frequency vibration motor. It has higher enrichment ratio and can adapt different particle size and concentration and grade of mineral ores. And also have advantages of reliable working and easy operation and maintenance.

Application scope:

It is suitable for the purification of iron and fine grained red ore (hematite limonite siderite, etc.) in non-metallic ore, such as kaolinite Advantages:

Advantages:

1,Vertical Swivel with High separation efficiency: Vertical Swivel rotation and back flush mineral

ores make the flat ring jam problem shooting.

2,Unique magnetic medium with high magnetic intensity: the company patented magnetic medium

could offer high gradient magnetic field with max. Magnetic intensity up to 20000Gs.

3,Good cooling effect with stable magnetic field. The excitation coil adapt hollow tube with higher

thickness. The water could flow through tube and take away the heat after water circulation

4,Widely used for different field and no need maintenance.

Working principle:

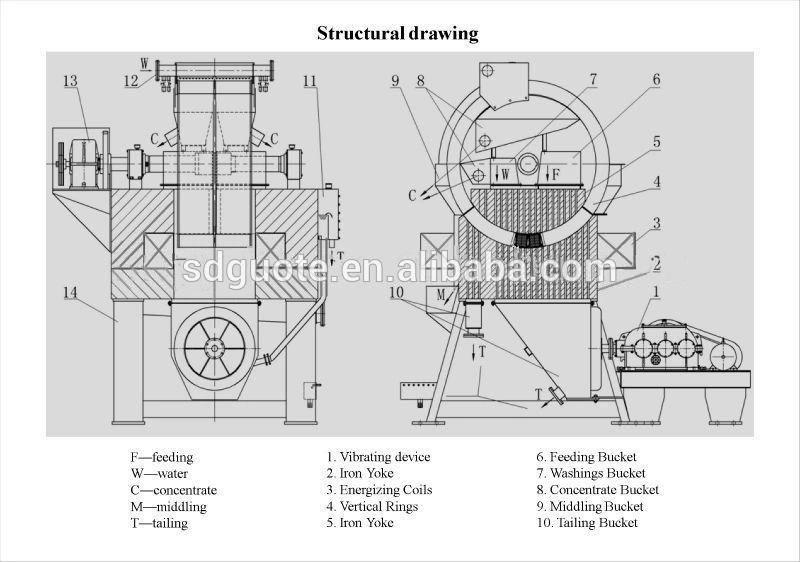

Pulp through the feeding tube into the feed hopper, pulp along the magnetic gap through the swivel,

high permeability of the stainless steel rods inside the ring of the magnetic induction medium

magnetized in the background magnetic field, form a high gradient magnetic field, magnetic medium

pulp in the magnetic particles are adsorbed on the surface of magnetic medium,

the swivel rotation was taken to to the top of the magnetic field area, by flushing with rinse water

pressure, the magnetic materials into concentrate in the bucket, non-magnetic particles along the

magnetic gap into the tailings under drained bucket in order to realize the separation of material

Swivel lower magnetic medium of submerged within the ore slurry surface,at the same time of slurry injection, installed at the side of the tailings boxes of reciprocating motion

stroke box constantly doing, make through tympanic membrane separation indoor pulp do fluctuate,the pulsating flow physical ore grain group always maintain loose state in the process of sorting,

effectively remove the particles in material, significantly improve the grade of concentrate

Contact Information:

Contact Information:

International Marking Manager: Ms. Yolanda