Air Sept Coal Ball Mill Model Mq2244 with Capacity 8tph

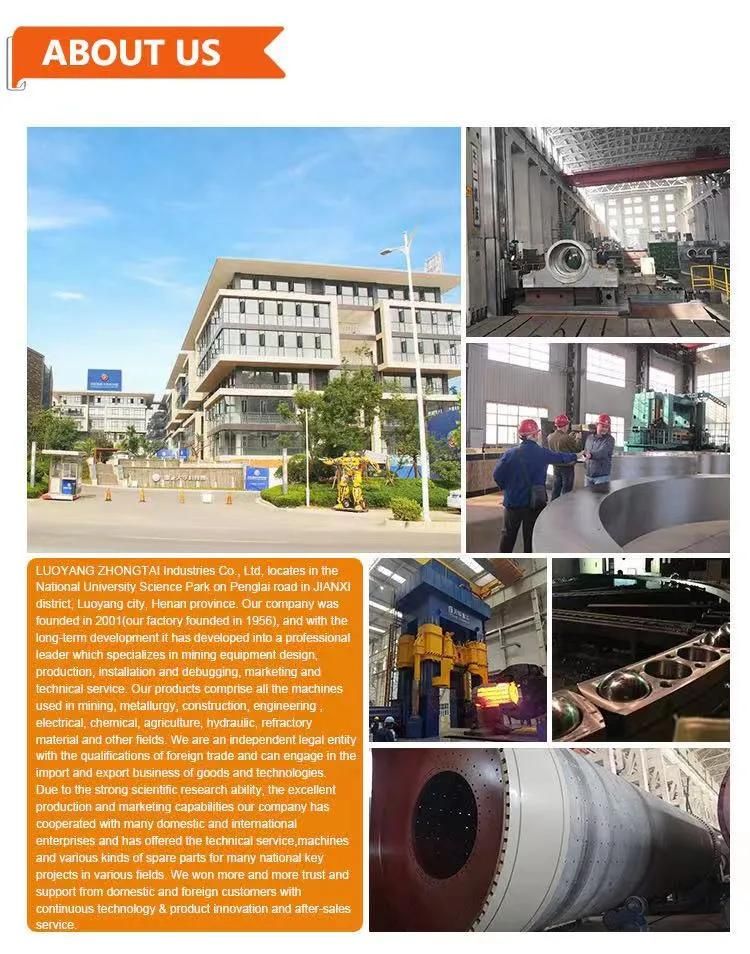

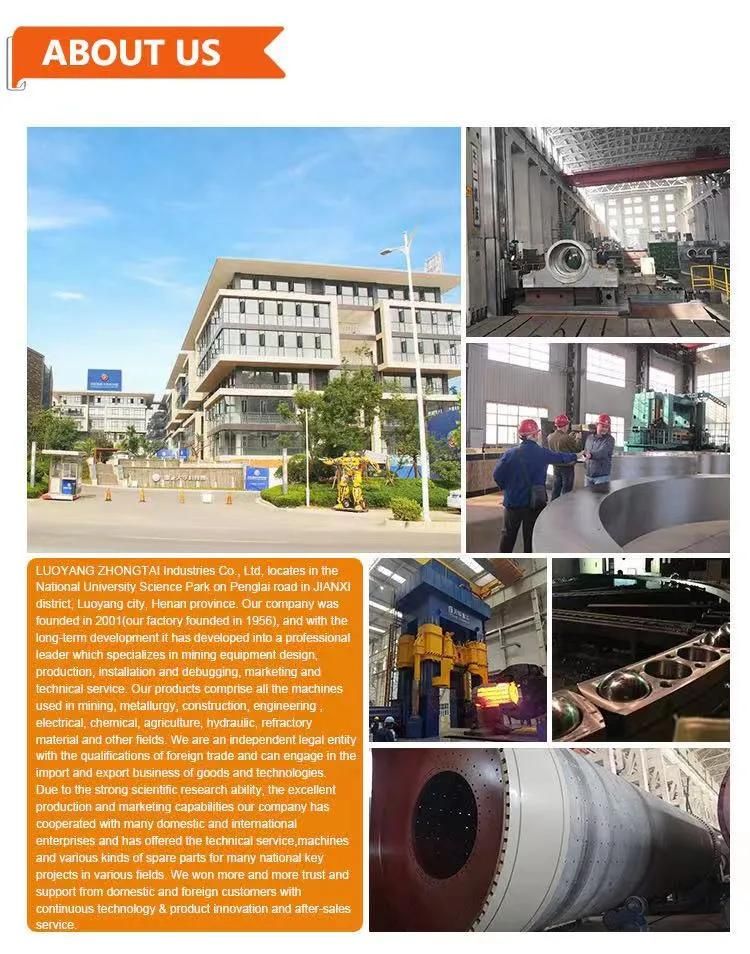

Luoyang Zhongtai Industries Co., Ltd.- Type:Ball Mill

- Motor Type:AC Motor

- Motor Power:60-5500 Kw

- Rotationl Speed:17-19r,min

- Application:Mine

- Materials:for Mining Grinding

Base Info

- Model NO.:MQ2244

- Condition:New

- Warranty:a Year

- After-sales Service:Twenty Four Hour Online

- Overflow Ball Mill:1.5X3.0~ 8X12m Ball Mill

- Wet Grate Ball Mill:1.2X2.4~4X14m Ball Mill

- Capacity:5-500 Tph

- Effective Volume:2.2~157m3

- Normal Feed Sizes:80% Passing 1,4" (6 mm or Finer) for Hard Ores @

- Large Open Gear:Agma Standard

- Control and Protection System:Controlled by PLC.

- Weight:18-560t

- Max. Ball Loading Capacity:9-350 T

- Power:95-5500kw

- Transport Package:Mine Ball Mill

- Specification:Mine Ball Mill

- Trademark:ZTIC

- Origin:Luoyang, Henan

- HS Code:847420200

- Production Capacity:1000PCS,Year

Description

Overview

Product Description

Cylinder lengthEffective volume Rotate speed Max. ball loading capacity Motor

Size

(L×W×H)

WeightPower Speed mm mm m3 r/min t kw r/min m t MQS12×24 1500 3000 5 26.6 9 95 742 6.4×2.9×2.6 18 MQS15×15 1500 1500 2.3 29.2 4.8 60 725 5.7×3.2×2.8 13.7 MQS15×24 1500 2400 3.7 29.2 7.6 90 730 6.9×3.3×2.8 16.5 MQS15×30 1500 3000 4.6 26.6 10 90 742 7.6×3.4×2.8 19.5 MQS21×30 2100 3000 9.4 22.1 20 220 740 8.5×4.65×3 45 MQS24×30 2400 3000 12.2 21 25 250 980 8.8×4.7×4.4 55 MQS24×70 2400 7000 26.66 21 54 475 740 14.3×5.8×4.4 67 MQS27×21 2700 2100 10.6 19.7 22 280 733 9.7×6.5×4.8 69 MQS27×36 2700 3600 18.5 20.5 39 400 187.5 12×5.8×4 74 MQS27×40 2700 4000 20.5 20.24 38 400 187.5 12.4×5.8×4.7 77 MQS27×60 2700 6000 34.34 19.5 53 630 589 12×5.7×4.5 84 MQS29×41 2900 4100 26 19.34 42 450 740 9.9×6.1×5.1 76.1 MQS31×64 3100 6400 43.7 18.3 56 1000 167 15.2×6.98×5.8 141 MQS32×31 3200 3100 22.65 18.3 46.9 500 167 13.9×7.3×6.0 109 MQS32×36 3200 3600 26.3 18.3 54 630 167 14.3×7.3×6.0 116.94 MQS32×40 3200 4000 29.2 18.2 60 710 980 14.7×7.3×6.0 121.4 MQS32×45 3200 4500 32.9 18.3 68.5 800 167 15.2×7.3×5.9 126.23 MQS32×54 3200 5400 39.4 18.3 81.6 1000 167 16.6×7.3×6.1 135.4 MQS36×45 3600 4500 41.4 17.25 86 1000 167 13.5×7.3×6.3 153.1 MQS36×60 3600 6000 54 17.3 112 1400 167 15.5×8.3×6.3 190.6 MQS36×85 3600 8500 79 17.4 144 1800 743 20×8.2×7.1 260.89 MQS40×60 4000 6000 69.8 16.0 126 1500 200 17.4×9.34×7.5 215.5 MQS40×67 4000 6700 76 16.0 155 1600 980 16×8.43×7.5 235.2 MQS40×13.5 4000 13500 157 16.5 280 3300 980 24.2×9.9×7.8 284/375

2.Main Technical Parameters of Overflow Ball Mill:

ModelCylinder diameter Cylinder length Effective volume Rotate speed Max. ball loading capacity Motor

Size

(L×W×H)

Weightmotor speed mm mm m3 r/min t kw r/min m t MQY15×30 1500 3000 5 26.6 9 95 742 7.4×3.4×2.8 18.5 MQY15×36 1500 3600 5.7 26.6 10.6 95 742 8.0×3.4×2.8 17.22 MQY18×61 1830 6100 13.4 24.5 24.6 220 736 10.2×5.1×4.0 37.3 MQY21×30 2100 3000 9.4 22.1 15 200 740 8.5×4.65×3 45 MQY24×30 2400 3000 12.2 21 22.5 250 980 8.8×4.7×4.4 55 MQY24×70 2400 7000 26.66 21 48 475 740 14.3×5.8×4.4 67 MQY27×36 2700 3600 18.5 20.5 39 400 187.5 9.8×5.8×4.7 61.34 MQY27×40 2700 4000 20.5 20.24 38 400 187.5 10.4×5.8×4.7 70 MQY27×45 2700 4500 23.5 20.5 43.5 500 187.5 12.5×5.8×4.7 76 MQY27×60 2700 6000 34.34 19.5 53 630 589 13.5×5.9×4.7 71.2 MQY28×54 2800 5400 30 19.5 55.2 630 167 13×5.83×4.7 97.8 MQY28×80 2800 8000 43 20 78.6 800 137 16.5×7.3×5 115 MQY30×11 3000 11000 69.2 17.3 100 1250 429 28.9×3.8×5 227.8 MQY32×36 3200 3600 26.3 18.3 48.4 500 167 14.3×7.3×6 116.94 MQY32×40 3200 4000 29.2 18.2 60 560 980 16.7×7.3×6 121.4 MQY32×45 3200 4500 32.9 18.3 60.5 630 167 13×7.0×5.82 124.23 MQY32×54 3200 5400 39.4 18.3 73 800 167 14.2×7.0×5.82 129 MQY32×64 3200 6400 46.75 18.3 86 1000 167 15.2×7.0×5.8 140 MQY32×75 3200 7500 55.5 18.3 102 1250 743 17.7×8.4×6.3 154 MQY32×90 3200 9000 64.2 18.3 106.6 1250 150 18.5.7.3×6 173 MQY34×45 3400 4500 37 18.4 74.6 800 167 11.5×7×6.1 129.8 MQY34×56 3400 5600 45.8 17.9 84.3 1120 985 16.7×7.6×6.3 MQY36×45 3600 4500 41.4 17.25 76 1000 167 13×7.3×6.3 144.1 MQY36×50 3600 5000 46.7 17.5 85.96 1250 167 15×7.6×6.2 150 MQY36×50 3600 5000 46.7 17.3 85.96 1250 429 23×4.6×6.3 176 MQY36×56 3600 5600 55.4 17.76 106.3 1250 750 14.4×8×6.3 159.7 MQY36×60 3600 6000 55.7 17.3 102.5 1250 429 24×4.6×6.3 138.73 MQY36×60 3600 6000 54 17.3 102 1250 167 15.6×8.3×6.3 162.7 MQY36×61 3600 6100 55.36 17.76 106.3 1200 980 15.8×8.5×6.2 164.1 MQY36×85 3600 8500 79 17.4 131 1800 743 20×8.2×7.1 251.89 MQY36×90 3600 9000 83.5 17.4 138 1800 743 28×4.6×5.6 286 MQY38×67 3800 6700 70 16.5 130 1400 743 19×8.2×7.1 185.2 MQY40×60 4000 6000 69.8 16.0 126 1500 200 17.4×9.5×7.6 203.5 MQY40×67 4000 6700 78 16.0 136.3 1600 200 15.6×9.6×7.3 206.2 MQY40×135 4000 13500 155 16 233 3300 200 23×10×4.9 343 MQY43×61 4270 6100 80 15.67 144 1750 200 14×10×7.7 215.3 MQY50×64 5030 6408 120 14.4 251 2600 200 14.6×11×9.1 318.5 MQY50×83 5030 8300 152.3 14.4 266 3300 200 22×10.5×9 402.6 MQY55×65 5500 6500 143.3 13.8 264 3400 200 18.5×9.8×8.9 451.5 MQY50×85 5500 8500 187.4 13.8 335 4500 200 20.5×12×9.8 MQY55×65 5500 6500 143.3 13.8 264 3400 200 MQY50×85 5500 8500 187.4 13.7 335 4500 200 MQY55×88 5500 8800 191.5 13.7 MQY60×95 6700 9500 249.3 13 MQY67×116 6700 11600 385 12.5 MQY73×115 7300 11500 495 12 MQY80×120 8000 12000 570.5 11.5

Cement Ball mill is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of ores. Cement ball mill is not only suitable for over-flow grinding, but also applicable for cyclic close-flow grinding together with powder collector.

Cement ball mill is an efficient tool for fine powder grinding. The Cement ball mill is used to grind many kinds of mine and other materials, or to select the mine. Cement ball mill is widely used in building material, chemical industry, etc. There are two ways of grinding: the dry way and the wet way. It can be divided into tabular type and flowing type according to different expelling mine.

LYHMC Cement ball mill Feature:

1.The cylindrical mill adopts the driving type edge-driving, center-driving, edge-driving with multi-point meshing, etc; driven by asynchronous motor +reducer +pinion and gear as well as synchronous motor +

air lclutch + pinion and gear.

2.Generally supported by static-dynamic pressure bearing on both ends. Fuuly closed self-aligning 120º osculation rocker bearing is used. Also single or double slipper staic- dynamic bearings can be used. The bush is made by NC machine.

3 .The large open gear is designed using AGMA standard, Equipped with reliably sealed gear housing and grease ahtomatic spraying lubrication system.

The shell is key part of a mill. Carry out finite element analysis on it with computer to ensure the reliable operation;

4 .The shell is automatically welded, ultrasonic inspected, wholly annealed and machined by large special machine tools on one chucking; there special seal on static-dynamic connection parts , ch as feed and discharge hoper, trunnion, etc, to prevent oil and slurry leakage;

5 .The liner is of wear-resistance material mad by our company, wich has been specially heat-treated, with high hardness and long service life. Also other wear-resistance casting or rubber liner can be used;

6. There are slow speed drive for medium and large mill;

7.The high and low pressure lubricating station is equipped for medium and large mill;

8.The control and protection system is controlled by PLC. technical advantages

1. High capacity and Low consumption: the capacity of SCM series super-micro mill, compared with that of jet mill and mixing mill, has been improved by 40% under the same final fineness and electric power.

2. High fineness and Flexible adjustment: the final fineness can be adjusted from 325 meshes to 2500 meshes according to the requirements, and the fineness can reach D97≤5um.

3. Trustworthy security: there is no rolling bearing and bolt in the mill chamber, therefore, the bearing and sealing elements will not wear out easily, and the bolts will not loose to make damage to the equipment.

4. Clean and environment-friendly: equipped with the pulse filter and sound absorber, the mill reaches the environment-friendly standard of our country and reduces the dust and noise greatly.

Cement Ball mill working principle

Cement Ball mill Main feature and working principle

2.1 Cement Ball mill Main feature

This mill is center driven, which adopts slipper bearing support, new type combination design baffle plates and discharge grate, to raise crushing, grinding and screening efficiency. 2.2

Working principle

The material is fed into the rough grinding bin through the feeding device; then crushed under the impact and grinding of grinding agent (steel ball with longer diameter), and the finer material enter into the fine grinding bin through double layered baffle plates and other material which can not enter into the fine grinding bin will continue be crushed in the rough grinding bin; the material which enter into fine grinding bin will entail further impact and grinding of smaller grinding agent, and the finished goods which meet the degree of fineness will enter into discharging device and been discharged from the mill.

3.Structure introduction

The mill mainly consists of feeding device, slipper bearing, rotating part, discharging device, lubricating device of slipper bearing. 3.1 Feeding device

Cement Ball Mill | Technical parameters

NOModel (m) Production capacity t/h Speed r/min Feed in size

mm medium load t Effective volume Main motor Size Weight (T) Power kw Voltage V L W H 1 Φ2.2×6.5 13-14 22 <25 31 21.4 380 6000 12385 5390 4210 53 2 Φ2.2×11 15-16 21 <25 50 36 630 6000 21559 4540 3520 109 3 Φ2.2×13 16-18 21.5 <25 60 43 630 6000 26079 4540 3520 114.2 4 Φ2.4×8 15 20.8 <25 45 30 560 6000 17215 5564 4540 82.53 5 Φ2.4×13 20-23 19 <25 65 51.7 800 6000 27580 4540 3620 138 6 Φ2.6×13 30-32 19.6 <25 80 60 1000 6000 20883 7740 5670 144.5 7 Φ3×9 28-32 17.8 <25 70-80 55 1000 6000 23568 4760 3670 138.7 8 Φ3×11 36-40 18.9 <25 100 69 1250 6000 27610 5720 4080 181.9 9 Φ3×11 36 17.69 <25 100 69 1250 6000 24567 7510 5968 156.5 10 Φ3.2×11 40-45 17.4 <15 90-100 78 1250 6000 28000 5720 3672 180 11 Φ3.5×9.5 40 18 <20 115 76.4 1400 6000 29717 5250 5000 194.4 12 Φ3.5×11 45 17.2 <15 116 78.5 1600 6000 28454 5350 5600 271.64 13 Φ3.6×8.5 60 16.5 <20 102 86 2500 6000 19693 4141 5404.5 233.3* 14 Φ3.8×9 70-80 16.5 <20 130 94 2000 6000 28521 5550 5600 255.2 15 Φ3.8×12.5 55 16.4 <25 167 123.5 2500 6000 17419 10745 8204 301.4 16 Φ3.8×13 60 16.3 <25 173 128 2500 6000 19693* 4141* 5404.5 223.3* 17 Φ4.2×11 120 15.75 ≤3 80%pass 182 134.5 2800 18500 4400 6500 256** 18 Φ4.2×11.5 130 15.99 ≤3 80%pass 199 138 2800 10000 18002 8962 7520 219** 19 Φ4.2×11.5 130 16 ≤3 80%pass 199 138 2800 17259 4960 5600 220** 20 Φ4.2×12.5 85 16 ≤25 90% 210 151 3150 18400 4960 8640 251** 21 Φ4.2×12.5 145 16 ≤3 80% 210 151 3150 18400 4960 8640 242** 22 Φ4.2×13 75 15.6 ≤25 90% 209 157 3150 174450 4880 8000 255** 23 Φ4.2×13 150 15.6 ≤3 80% 209 157 3150 17445 4880 8000 256** 24 Φ4.2×13.5 80-85 15.8 ≤25 90% 230 164 3550 17744 6700 6010 256** 25 Φ4.2×14 95 15.6 ≤25 90% 252 169 3550 19055 20490 23200 220** 26 Φ4.2×14.5 95 15.8 ≤25 80% 250 178 4000 5050 6700 11054 278** 27 Φ4.6×14 95-110 15 285 185 4200 6000 23200 11054 6370 310**

FAQ

Quality Control

Physical & Chemical Identification Center

ZTIC owns a professional testing and metrology institute which provides advanced testing methods such as nondestructive testing, industrial chemical analysis, metallographic testing and analysis, mechanical testing, sample preparation, meter/length measurement, weighing apparatus verification, and weighman inspection. Our metrology institute has taken a leading role in China.

ZTIC owns nearly two hundred types of advanced testing equipment, nine different measurement standards and nearly twenty types of world-class testing equipment which have been imported from international locations such as Germany, Japan, USA, UK and Belgium.

Quality testing equipment

Spectrometer

Ultrasonic flaw detector

Carbon and sulfur analyzer

X-ray detection apparatus

Brinell microscope

Leeb hardness tester

FAQ

FAQ

Cylinder

diameter

Cylinder length

Size

(L×W×H)

Weight

2.Main Technical Parameters of Overflow Ball Mill:

Model

Size

(L×W×H)

Weight

Cement Ball mill is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of ores. Cement ball mill is not only suitable for over-flow grinding, but also applicable for cyclic close-flow grinding together with powder collector.

Cement ball mill is an efficient tool for fine powder grinding. The Cement ball mill is used to grind many kinds of mine and other materials, or to select the mine. Cement ball mill is widely used in building material, chemical industry, etc. There are two ways of grinding: the dry way and the wet way. It can be divided into tabular type and flowing type according to different expelling mine.

LYHMC Cement ball mill Feature:

1.The cylindrical mill adopts the driving type edge-driving, center-driving, edge-driving with multi-point meshing, etc; driven by asynchronous motor +reducer +pinion and gear as well as synchronous motor +

air lclutch + pinion and gear.

2.Generally supported by static-dynamic pressure bearing on both ends. Fuuly closed self-aligning 120º osculation rocker bearing is used. Also single or double slipper staic- dynamic bearings can be used. The bush is made by NC machine.

3 .The large open gear is designed using AGMA standard, Equipped with reliably sealed gear housing and grease ahtomatic spraying lubrication system.

The shell is key part of a mill. Carry out finite element analysis on it with computer to ensure the reliable operation;

4 .The shell is automatically welded, ultrasonic inspected, wholly annealed and machined by large special machine tools on one chucking; there special seal on static-dynamic connection parts , ch as feed and discharge hoper, trunnion, etc, to prevent oil and slurry leakage;

5 .The liner is of wear-resistance material mad by our company, wich has been specially heat-treated, with high hardness and long service life. Also other wear-resistance casting or rubber liner can be used;

6. There are slow speed drive for medium and large mill;

7.The high and low pressure lubricating station is equipped for medium and large mill;

8.The control and protection system is controlled by PLC. technical advantages

1. High capacity and Low consumption: the capacity of SCM series super-micro mill, compared with that of jet mill and mixing mill, has been improved by 40% under the same final fineness and electric power.

2. High fineness and Flexible adjustment: the final fineness can be adjusted from 325 meshes to 2500 meshes according to the requirements, and the fineness can reach D97≤5um.

3. Trustworthy security: there is no rolling bearing and bolt in the mill chamber, therefore, the bearing and sealing elements will not wear out easily, and the bolts will not loose to make damage to the equipment.

4. Clean and environment-friendly: equipped with the pulse filter and sound absorber, the mill reaches the environment-friendly standard of our country and reduces the dust and noise greatly.

Cement Ball mill working principle

Cement Ball mill Main feature and working principle

2.1 Cement Ball mill Main feature

This mill is center driven, which adopts slipper bearing support, new type combination design baffle plates and discharge grate, to raise crushing, grinding and screening efficiency. 2.2

Working principle

The material is fed into the rough grinding bin through the feeding device; then crushed under the impact and grinding of grinding agent (steel ball with longer diameter), and the finer material enter into the fine grinding bin through double layered baffle plates and other material which can not enter into the fine grinding bin will continue be crushed in the rough grinding bin; the material which enter into fine grinding bin will entail further impact and grinding of smaller grinding agent, and the finished goods which meet the degree of fineness will enter into discharging device and been discharged from the mill.

3.Structure introduction

The mill mainly consists of feeding device, slipper bearing, rotating part, discharging device, lubricating device of slipper bearing. 3.1 Feeding device

Cement Ball Mill | Technical parameters

NO

mm

FAQ

Quality Control

Physical & Chemical Identification Center

ZTIC owns a professional testing and metrology institute which provides advanced testing methods such as nondestructive testing, industrial chemical analysis, metallographic testing and analysis, mechanical testing, sample preparation, meter/length measurement, weighing apparatus verification, and weighman inspection. Our metrology institute has taken a leading role in China.

ZTIC owns nearly two hundred types of advanced testing equipment, nine different measurement standards and nearly twenty types of world-class testing equipment which have been imported from international locations such as Germany, Japan, USA, UK and Belgium.

Quality testing equipment

Spectrometer

Ultrasonic flaw detector

Carbon and sulfur analyzer

X-ray detection apparatus

Brinell microscope

Leeb hardness tester

FAQ

FAQAfter Sales Service

ZTIC Heavy Industries is your business partner in the After Market.

ZTIC able to provide:

1. ENGINEERED SPARES - DESIGN AND MANUFACTURING

2. LARGE VOLUME STEEL AND IRON CASTING FOUNDARIES

3. HUGE MACHINE SHOP CAPABILITIES

4. TRAINING PROGRAMMES

5. PREVENTATIVE MAINTENANCE PROGRAMS

6. PREVETATIVE MAINTENANCE SERVICES

7. COMPREHENSIVE MAINTENANCE PROGRAMS