Auto Centering Vibrating Screen

Blackstone International Company Limited- Type:Auto Centering Vibrating Screen

- Certification:ISO9001:2000

- Energy Saving:Energy Saving

- Condition:New

Base Info

- Model NO.:Auto Centering Vibrating Screen

Description

Basic Info.

Model NO. Auto Centering Vibrating ScreenProduct Description

Auto Centering Vibrating Screen

[Introduction] It is widely used in mining, construction and chemical industry, mostly for medium and fine particles screening.

[Capacity] 20-300 t/h.

[Application] It is suitable for classification of medium and fine-grained materials in mining, metallurgy, building materials, chemical industry, etc.

[Improvement] The screening equipment uses wear-resistant rubber to make elastic limit parts and adopts modern mine new technology.

Advantages

- Vibrating screen has a large amplitude and high screening efficiency.

- It can provide a wear-resistant rubber screen with long service life.

- It can provide wear-resistant rubber spring with high elasticity, long service life, low noise and convenient maintenance.

- Seat type and hanging type are available.

- Vibrating screen has good stability.

- The material on the screen of a self-centered vibrating screen can achieve good looseness and stratification under the action of vibration.

- The weight of the vibrating screen can be adjusted, and the amplitude of the screen can be adjusted according to the production requirements.

- When the ORE-FEEDING quantity changes, the amplitude also changes; when the ORE-FEEDING quantity is small, the amplitude increases and the vibration intensifies, and when the ORE-FEEDING quantity is large, the amplitude decreases.

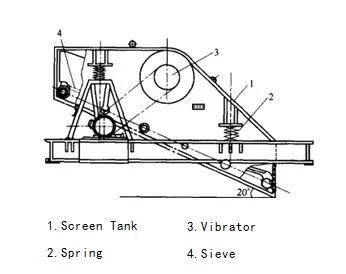

Structure

The centrifugal inertia force produced by the main bearing of the belt pulley driven by the motor is applied to the internal force of the vibration system of the screen box, which drives the center of gravity of the screen box to do the circular motion. The mass of eccentric weights on the bias wheels should ensure that the centrifugal inertia force produced by them can balance the centrifugal inertia force produced by the rotation of the sieve box.

The condition that the center of the pulley does not displace in space is that the centrifugal inertia produced by the rotation of the sieve box is equal to the centrifugal inertia force produced by the eccentric weight block, and in the opposite direction, the dynamic balance is achieved at this time. Thus, the self-centering of the pulley can be realized, so that the center distance between the large and small pulleys remains unchanged, eliminating the phenomenon of belt loosening and tightening.

Technical Parameter

Model | Specification | Feeding Size mm | Capacity t/h | Motor | Power kw | Weight kg | Type |

SZZ0918 | 900×1800 | ≤40 | 20~25 | Y100L1-4 | 2.2 | 420 | Hanging |

SZZ0918 | 900×1800 | ≤40 | 10~30 | Y100L1-4 | 2.2 | 553 | Seat |

SZZ20918 | 900×1800 | ≤40 | 20~40 | Y100L1-4 | 2.2 | 570 | Seat |

SZZ1225 | 1250X2500 | ≤100 | 100 | Y132S-4 | 5.5 | 1017 | Hanging |

SZZ1225 | 1250X2500 | ≤100 | 100 | Y132S-4 | 5.5 | 1466 | Seat |

SZZ21225 | 1250X2500 | ≤100 | 100~150 | Y132S-4 | 5.5 | 1320 | Hanging |

SZZ21225 | 1250X2500 | ≤100 | 100~150 | Y132S-4 | 5.5 | 1870 | Seat |

SZZ1530 | 1500×3000 | ≤100 | 90~200 | Y132M-4 | 7.5 | 1850 | Hanging |

SZZ1530 | 1500×3000 | ≤100 | 90~200 | Y132M-4 | 7.5 | 2665 | Seat |

SZZ21530 | 1500×3000 | ≤100 | 90~200 | Y132M-4 | 7.5 | 2963 | Hanging |

SZZ1540 | 1500×4000 | ≤100 | 90~200 | Y160L-4 | 15 | 2865 | Seat |

SZZ21540 | 1500×4000 | ≤400 | 90~200 | Y160L-4 | 15 | 3412 | Seat |

SZZ1836 | 1800×3600 | ≤150 | 100~300 | Y160M-4 | 11 | 4500 | Hanging |

SZZ21836 | 1800×3600 | ≤150 | 100~300 | Y180M-4 | 18.5 | 5616 | Seat |