Rotary Kiln Section Shell Manufacture

Xinxiang Great Wall Machinery Co., Ltd.- Certification:ISO9001:2015

- Material:Steel

- Weight:> 1 Ton

- Transport Package:Package Adapting to Ocean Transport

- Specification:Customzied

- Trademark:CHAENG

Base Info

- Origin:China

- Model NO.:OEM

- Production Capacity:50000 Tons,Year

Description

Basic Info.

Model NO. OEM Origin China Production Capacity 50000 Tons/YearProduct Description

Rotary kiln can be divided into cement rotary kiln, metallurgical rotary kiln, chemical rotary kiln and lime rotary kiln according to different materials. Regardless of the type of kiln, the kiln shell is a key component of the equipment.

| Weight | > 1 Ton |

| Material | Boiler plate, Q235C plate |

| Application | Rotary Kiln |

| Customizable | Yes, based on user's drawings |

CHAENG has strong casting and machining capabilities, and large annual output. We strictly follows the level-2 national inspection standard and implements 360° non-destructive testing system to ensure the quality of parts.

Production strength:

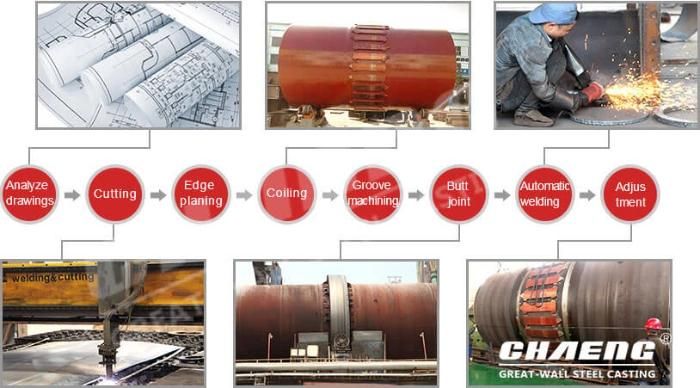

Process

The rotary kiln shell is rolled from steel plates such as boiler plates and Q235C plates, and requires highly on dimensional accuracy and geometric tolerances. Its processing quality directly affects the strength and tightness of the component.

According to the detailed requirements of the drawings, and adopting the local forming method, the specific manufacturing process and welding method of single-section kiln shell are formulated. After the kiln shell is assembled and welded, post-weld processing is required, including non-destructive testing, post-weld heat treatment, pressure-resistant experiments and other technological processes to ensure the high quality of kiln shell.

Case

CHAENG has close cooperation with many companies of various industries, supplying them with spare parts with good performance to improve the practical effect and extend the service life of the equipment. CHAENG has won the high praise of customers!