Customized Cast Steel Ball Mill Trunnion/Head for Cement Industry

Xinxiang Great Wall Machinery Co., Ltd.- Certification:CE, ISO 9001:2008

- Standard:ASME, ASTM, DIN

- Surface Treatment:Polishing

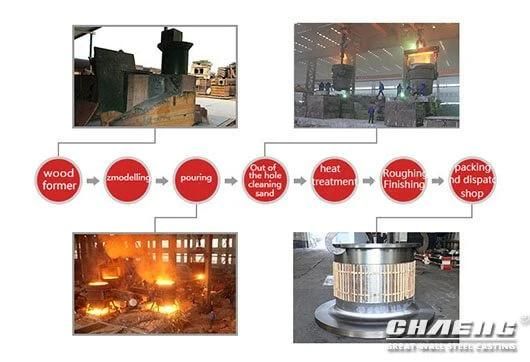

- Manufacturing Process:Casting

- Material:Cast Steel

- Transport Package:Ball Mill Trunnion Standard Packaging

Base Info

- Model NO.:Ball Mill Trunnion

- Specification:customize

- Trademark:CHAENG

- Origin:Xinxiang City, Henan Province, China

- HS Code:8487900000

- Production Capacity:3000 Pieces , Year

Description

Case

CHAENG ball mills are exported to more than 50 countries and regions, and the matched ball mill trunnion are all independently manufactured.

Chaeng Service

1. Cost-effective

CHAENG has the advanced casting equipment, strictly follows the national lever-2 detection standards, and executes 360° all-round nondestructive testing system, to ensure the reliable quality and long service life of steel castings. CHAENG is hailed as "high cost-effective steel castings manufacturer".

2. Fast delivery

CHAENG has strong technical teams, detailed production scheduling, wide range of raw materials purchase channels, and perfect logistics delivery system, making efforts to achieve as fast delivery period as required.

3. "Three-heart" service

The 24h fast response and the customer services in all 365 days rest your heart when you make choice, ease your heart when you use the products, satisfy your heart when you enjoy the services.