Dry Grinding Bauxite Ball Mill, Bauxite Ball Mill Machine

Zhengzhou Hengxing Heavy Equipment Co., Ltd.- Type:Ball Mill

- Motor Type:Stepper Motor

- Motor Power:22KW

- Rotationl Speed:20-22r,min

- Application:Iron Ore, Copper, Quartz, Stone

- Materials:Mine

Base Info

- Model NO.:2100*7000

- Condition:New

- Certificate:ISO9001-2008

- Motor:Made in China or According to Your Need

- Spare Parts:Supply

- Guarantee:1year

- Mining Object:Metallic and Non-Metallic Ore Excavator

- Transport Package:Standard Container

- Specification:National

- Trademark:Hengxing

- Origin:Zhengzhou, China

- HS Code:84742020

- Production Capacity:3-40tph

Description

Basic Info.

Model NO. 2100*7000 Condition New Certificate ISO9001-2008 Motor Made in China or According to Your Need Spare Parts Supply Guarantee 1year Mining Object Metallic and Non-Metallic Ore Excavator Transport Package Standard Container Specification National Trademark Hengxing Origin Zhengzhou, China HS Code 84742020 Production Capacity 3-40tphProduct Description

Dry Grinding Bauxite Ball Mill ,Bauxite Ball Mill Machine:1.Introduction of the bauxite ball mill :

This series of gypsum grinding ball mill machine is suitable for cement,ore dressing, chemical, coal and refractory industry to operate fine grinding.Bearing-type drive cement clinker ball mill machine is a technological changing type, compared with the traditional cement clinker ball mill machine,15% lower operating current and reduce the starting current 50%, according to Babbitt burning, downtime, the phenomenon of stopping production, not enough to improve the ball concentricity, run instability, current fluctuated, wear serious phenomenon hollow shaft. While use of rolling bearing, the hollow shaft can continue to use, save 90% lubrication oil, improve the loading of 20%, increase production by 15%, 10% speed increase , each saving at 20%-30% power.

Dry Grinding Bauxite Ball Mill ,Bauxite Ball Mill Machine

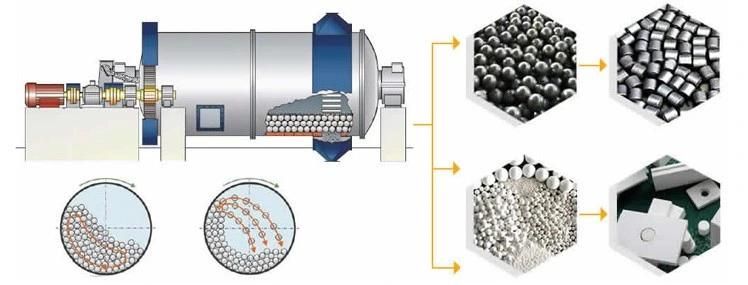

2.Working priciple ofthe bauxite ball mill:

1) This gypsum grinding ball mill is a horizontal type and tubular running device, has two chamber. This machine is grid type. The material enters first warehouse spirally and evenly along the input material hollow axis by input material device.

2) In this chamber, there is a ladder scaleboard or ripple scaleboard, and different specification steel balls. When shell rotates and it produces centrifugal force. At this time, steel balls will be carried to certain height and falls down to make the material heavy impact and grinded.

3) After being grinded coarsely in the first chamber, material enters second chamber for regrinding with the steel ball and scaleboard. At the end, the powder is discharged by output material board and the final products are completed.

3.bauxite ball mill technical parameters:

Model | Cylinder rotary speed (r/min) | Loading ball weight (t) | Input size (mm) | Discharge size (mm) | Capacity (t/h) | Motor power (kw) | Weight (t) |

Ø900×1800 | 39 | 1.5 | ≤20 | 0.075-0.89 | 0.8-2 | 18.5 | 4.6 |

Ø900×3000 | 39 | 2.7 | ≤20 | 0.075-0.89 | 1-4 | 22 | 5.6 |

Ø1200×3000 | 36 | 3.5 | ≤25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 |

Ø1200×4500 | 32 | 5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 |

Ø1500×3000 | 27 | 7.5 | ≤25 | 0.074-0.4 | 2-5 | 75 | 15.6 |

Ø1500×5700 | 28 | 12 | ≤25 | 0.074-0.4 | 3.5-6 | 130 | 24.7 |

Ø1830×3000 | 25 | 11 | ≤25 | 0.074-0.4 | 4-10 | 130 | 28 |

Ø1830×6400 | 24 | 21 | ≤25 | 0.074-0.4 | 7-16 | 210 | 34 |

Ø1830×7000 | 24 | 23 | ≤25 | 0.074-0.4 | 8-18 | 245 | 36 |

Ø2100×3600 | 23 | 19 | ≤25 | 0.074-0.4 | 10-36 | 210 | 46 |

Ø2200×4500 | 21 | 27 | ≤25 | 0.074-0.4 | 12-23 | 280 | 48.5 |

Ø2200×6500 | 21 | 35 | ≤25 | 0.074-0.4 | 14-26 | 380 | 52.8 |

Ø2200×7000 | 21 | 35 | ≤25 | 0.074-0.4 | 15-28 | 380 | 54 |

Ø2200×7500 | 21 | 35 | ≤25 | 0.074-0.4 | 15-30 | 380 | 56 |

Ø2400×4500 | 21 | 30 | ≤25 | 0.074-0.4 | 18-45 | 320 | 65 |

Ø2400×8000 | 20 | 36 | ≤25 | 0.074-0.4 | 20-48 | 410 | 81 |

Ø2700×3600 | 21 | 39 | ≤25 | 0.074-0.4 | 19-75 | 400 | 83 |

Ø2700×4000 | 20 | 40 | ≤25 | 0.074-0.4 | 20-78 | 400 | 85 |

Ø2700×4500 | 20 | 48 | ≤25 | 0.074-0.4 | 22-85 | 430 | 89 |

Ø3200×4500 | 18 | 65 | ≤25 | 0.074-0.4 | 29-140 | 800 | 137 |

Ø3200×5400 | 18 | 81.6 | ≤25 | 0.074-0.4 | 30-180 | 800-1000 | 146 |

Ø3600×4500 | 17 | 88 | ≤25 | 0.074-0.4 | 35-210 | 1000 | 190 |

Ø3600×6000 | 17 | 117 | ≤25 | 0.074-0.4 | 38-240 | 1250-1500 | 220 |

Ø3600×8500 | 17 | 144 | ≤25 | 0.074-0.4 | 45-260 | 1800 | 260 |

4.Main structure of tyhe bauxite ball mill:

Rotary Cylinder

Driving Device

Main Bearing

Feed Device

Discharge Device

5.ball mill in hengxing factory :

6.bauxite ball mill maintenance:

1.when the ball mill running,the main bearing temperature is not more than 55ºC

2.All lubricate oil should be put out after the ball mill continuously running one month,clean completely,replace new oil.and change oil every 6 months

3.Check the every lubrication point and oil surface hegith every 4 hours.

4.When the ball mill normally running,the driving bearing and the gearbox temperature is not more than 55ºC,the hihest not more than 60ºC

5.Every connection fastening parts no loose,joint surface is no oil leakage,no water leakage,ore leakage.

6.Girth gear gear face can be used sequentially with another side if one side is severe wear.

7.The liner bolts should be replaced if cause the liner loose.

8.The ball mill grid plate should be replaced if severe wear.

9.The ball mill liner should be replaced if 70% wear or have 70mm crack.

10.If find abnormal conditions,should stop and maintain.

About Installation and Commissioning :

we are able to guide the overall installation of whole set production line, including stone crushing production line and ball mill production line,rotary dryer production line, etc., which will allow you to start the normal operation of equipment immediately and successfully.

For more bauxite ball mill details,please contact :

Contact:

Ms Sara Pang