Fine Powder Ceramics Air Classifier for Silica Sand

Weifang Guote Mining Equipment Co., Ltd.- Type:Vertical Air Classifier

- Motor Type:AC Motor

- Motor Power:7-380

- Application:Mine

- Materials:Fine Sandstone

- Condition:New

Base Info

- Model NO.:GF

- Warranty:1 Year

- Features 1:Low Energy Consumption

- Features 2:Highly Advanced Classification

- Features 3:Low Failure Rate and Operation

- Nature:Cyclone Classification

- Product Type:Powder

- Certification:ISO9001:2008, ISO9001:2000,Ce

- Transport Package:Container or According Requirements

- Specification:200-325 mesh powder classification

- Trademark:Guote

- Origin:Weifang, Shandong

- HS Code:8445190000

- Production Capacity:50sets,Month

Description

Basic Info.

Model NO. GF Warranty 1 Year Features 1 Low Energy Consumption Features 2 Highly Advanced Classification Features 3 Low Failure Rate and Operation Nature Cyclone Classification Product Type Powder Certification ISO9001:2008, ISO9001:2000,Ce Transport Package Container or According Requirements Specification 200-325 mesh powder classification Trademark Guote Origin Weifang, Shandong HS Code 8445190000 Production Capacity 50sets/MonthProduct Description

Fine Powder Ceramics Air Classifier for Silica Sand

1. Applications of Air Classifiers:

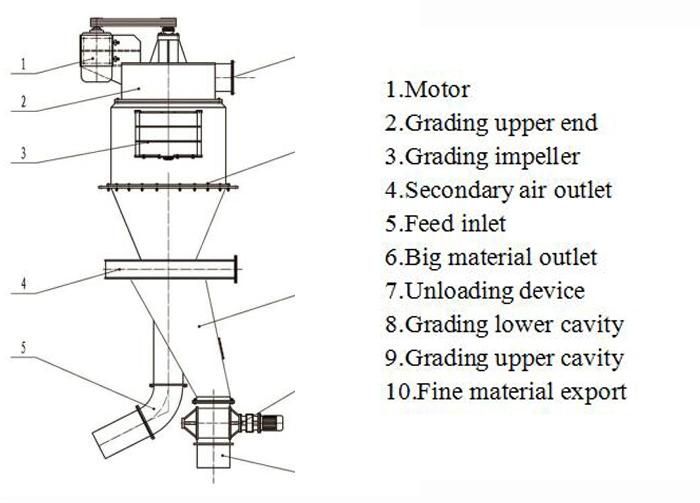

The classification device is composed of pneumatic classifier, cyclone, collector , induced draft fan,conmtrol cabinet etc . Equiped with second air inlet and vertical impeller rotor ,the materials are fed in visa the bottem roller under the force generated from the induced draft fan and then mixed with first input air to disperse particle and then brought to classifying zone .

Owing to the high rotary speed of classifying rotor, the particles are under the centrifugal force produced by the rotor and centripetal force generated from induced draft fan . When the centrifugal force is stronger than then centripetal force , the coarse particles fall down along inside roller. the second air is induced to sieve the coarse materials and seperate the fine powder that stick on or mixed with coarse . after the coarse material is discharged from classifier . the over -milled powder are collected by the cyclone and pulse collector .

2. Work Principle:

As a forced centrifugal classifier with secondary air entry and stand grading rotor, the classifier is composed of grading rotor, guide vane rectifier and screw feeder. The materials are fed through the upper cartridge and the grains will be sieved and well distributed by the incoming air, which brings the grain to the grading zone. The centrifugal force produced by the fast rotation of gather in the centripetal force by the pneumatic atheism act on the grading grains when the centrifugal force on the grain is greater than the centripetal force. The coarse grains above the grading range will be swirled down along the untrained wall, the second air will be rectified to uniform cockney through the guide wane and separate the thinner grains from the discharge port. The thinner grains below the grading range will be blasted to cyclone separator and collector whereas the purified air will be vented outside

3.Technical Parameter

| Model | Capacity(KG) | Classifying Efficiency(%) | product size(um) | power (KW) |

| GF010 | 10-50 | 70-90% | D97=5-50 | 7 |

| GF020 | 50-350 | 70-90% | D97=5-50 | 15-19 |

| GF050 | 100-800 | 70-90% | D97=5-50 | 25-30 |

| GF100 | 300-1500 | 70-90% | D97=5-50 | 41-48 |

| GF200 | 500-4000 | 70-90% | D97=5-50 | 63-73 |

| GF400 | 2000-5000 | 70-90% | D97=5-50 | 97-120 |

| GF500 | 3000-6000 | 70-90% | D97=5-50 | 110-130 |

| GF600 | 4000-8000 | 70-90% | D97=5-50 | 140-169 |

| GF800 | 6000-12000 | 70-90% | D97=5-50 | 170-210 |

| GF1200 | 8000-200000 | 70-90% | D97=5-50 | 230-380 |

4. Technical Features:

1,The classifier used within the ceramic protection, less equipment wear,no pollution,high purity.

2,classifier structure is designed,almost by all large particles, high grading precision,large granular control.

3,classification by grading impeller speed and fan free to adjust the air volume, in order to obtain the required product, grading range.

4,adopts low speed vertical single impeller hierarchical structure , material flow is stable, equipment processing capacity,high classification effciency.

5,using multi-stage structure,at the same time granularity classification of several products,the particle size distribution to obtain the ideal.

4. Product advantages:

1.With special design for classifying structure and its high classifying precision,it can block big granular strictly.

2.To get the required product,you can adjust the rotary speed of classifying wheel and air inlet volume.

3.Single vertical rotor with low speed,wteady flow field,high effciency and robust performance.

4.With multi-series structure, it can get products with different size to meet requirement.

FAQ:

FAQ:

Q: Why we believe in Weifang GuoteMining Equipment Company?

A: 1. More than 10 years experience.

Q. We are the leading professional supplier of mining equipments and service for quartz mining equipment industry.

A. All products achieved ISO9001:2000 quality management certificate and EU CE certificate.

Q: Delivery time

A: The lead time is 10-30 days, delivery time will vary depending on the type of the machine, shipping method selected and part availability.

Q: Payment terms

A: Accepted Payment Type: T/T, L/C, Western Union, Cash.

After sign the contract, pay the 30% deposit of total purchase price and pay the full payment before delivery.

Q: What will you do if the machine is broken down?

A: The Products warranty is one year. We will provide the technical advice and find the solution immediately for you when the machine is in trouble. For those wear parts, we guarantee the high quality parts for long-term supply.

Q: What should I do if I want to get a best quotation?

A: If you want a suitable type for you, please let us know your material and capacity.