Small Scale Relocatable Modular Gold Mining Flotation Plant

Yantai Huize Mining Engineering Co., Ltd.- Type:Gold Modular Plant

- Function:Gold Recovery

- Drive Mode:Electric Motor

- Voltage:Multiple Voltages

- Power:Multiple Power

- Application:Small Scale Gold Mines

Base Info

- Transport Package:Containerized

- Specification:Various

- Trademark:HZE

- Origin:China

- Production Capacity:15 Lines Per Year

Description

Basic Info.

Transport Package Containerized Specification Various Trademark HZE Origin China Production Capacity 15 Lines Per YearProduct Description

Small Scale Relocatable Modular Gold Mining Flotation Plant

Application

The relocatable modular flotation plant recovers gold from the sulfide ores. especially for high grade ores. The concentrate produced by flotation is sent to the next process, intensive cyanide leaching.

This flotation plant can be used as an independent pilot plant.

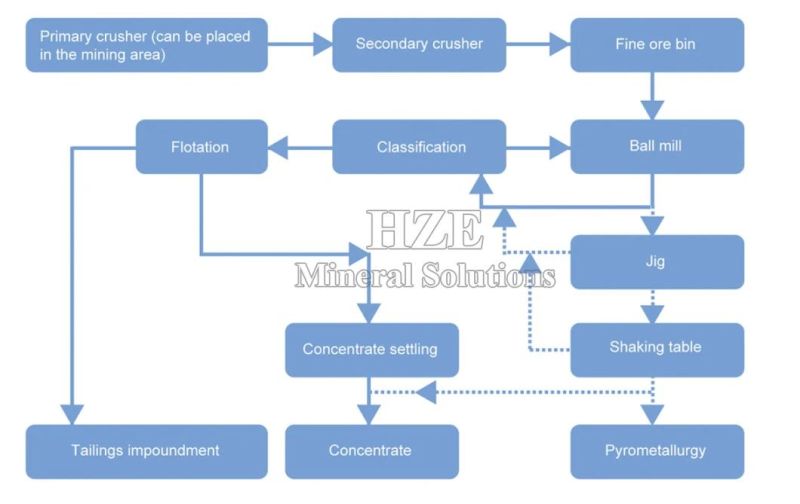

Main flowchart

Functional Module

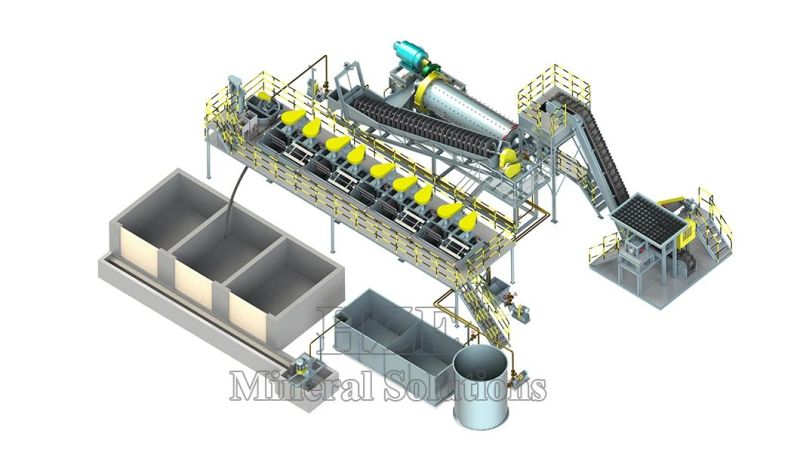

For the situations of raw materials and the customer's requirements, it is free to select the comminution module, grinding and classification unit, gravity concentration module, flotation module, concentrate settling module, water supply module and power supply module to form a complete plant which recovers gold as much as possible.

Crushing Module

The rocks are crushed to the qualified particle size for grinding. The module is composed of hoppers, crushers, belt conveyors, feeders and so on.

The ores are usually crushed in two stages. According to the actual situation of the site, the primary crusher can be mounted in the mining area or the processing plant. The crusher is usually driven by a diesel engine if it is located in the mining area.

Grinding and Classification Unit

The closed-circuit grinding and classification system consisting of the ball mill and spiral classifier can liberate ore into the suitable particles for recovering gold. The unit can be adjusted to a closed-circuit system consisting of the ball mill, slurry pump and hydrocyclone if the customer demands.

The grinding and classification unit is amounted in the whole steel frame.

Water Supply Module

It is composed of the water tanks, water pumps and water supply pipeline. The optimized water balance is achieved by the controlled the utilization rate of water.

Power Supply Module

It is composed of the diesel generators, distribution devices and the starting panels and so on. The module is suitable for the areas with inconvenient traffic and shortage of the power grid.

Note:

It is suggested to select the gravity concentration module to form a perfect combination to achieve the highest recovery if some coarse gold particles exist in the ore. The concentrate produced by gravity concentration can be mixed with flotation concentrate together or smelted separately.

If there are a large number of oxidized ores in the original ore besides sulfide ore, it is suggested that the carbon slurry carbon leaching process should be adopted directly in small-scale concentrators.

Special Functional Module

Flotation Module

This module is composed of the slurry conditioner, reagent solution preparation tanks and flotation cells. The reagents are made into solutions in the reagent solution preparation tanks. The overflow slurry coming from classification process is mixed uniformity with reagent solution by the slurry conditioner then it flows into a series of closed-circuit flotation cells to produce concentrate. A series of flotation cells are divided into rougher, cleaners and scavengers to ensure good recovery.

Concentrate Settling Module

The concentrate slurry flows into a set of pond to settle naturally, and the clarified water is recycled in the plant. The settled concentrate is packed into the bags artificially for transporting to the next processing, cyanide leaching.

Self-priming Flotation Machines

The flotation machine has large air suction capacity and low power consumption. Each cell has three functions: air inhaling, slurry suction and froth flotation. A certain number of flotation machines form a closed flotation circuit without any auxiliary equipment. All cells can be arranged horizontally. The flotation line and the number of cells of every stage can be adjusted at any time to achieve the best flotation effect according to the change of minerals.

There is an adjusting device at the discharge end of every flotation stage which is very convenient to adjust the slurry level. There are backward blades on both sides of the impeller, which can cause the reasonable slurry circulation and avoid coarse particles precipitation.

The chamber between the impeller and stator becomes a negative pressure zone during the impeller rotating. Air and slurry are sucked into the chamber forced by the negative pressure, and fully mix together to generate many small bubbles adhered by the useful mineral particles. The bubbles float up to recover gold well.

Specifications

| Model Item | HZF-1 | HZF-2 | HZF-3 | HZF-5 |

| Capacity(MT/h) | 1 | 2 | 3 | 5 |

| Inlet size D80(mm) | 18 | 18 | 18 | 18 |

| Grinding size (mesh) | 150 | 150 | 150 | 150 |

| Ambient temperature (ºC) | -15~45 | -15~45 | -15~45 | -15~45 |

| Gold recovery (%) | >92 | >92 | >92 | >92 |

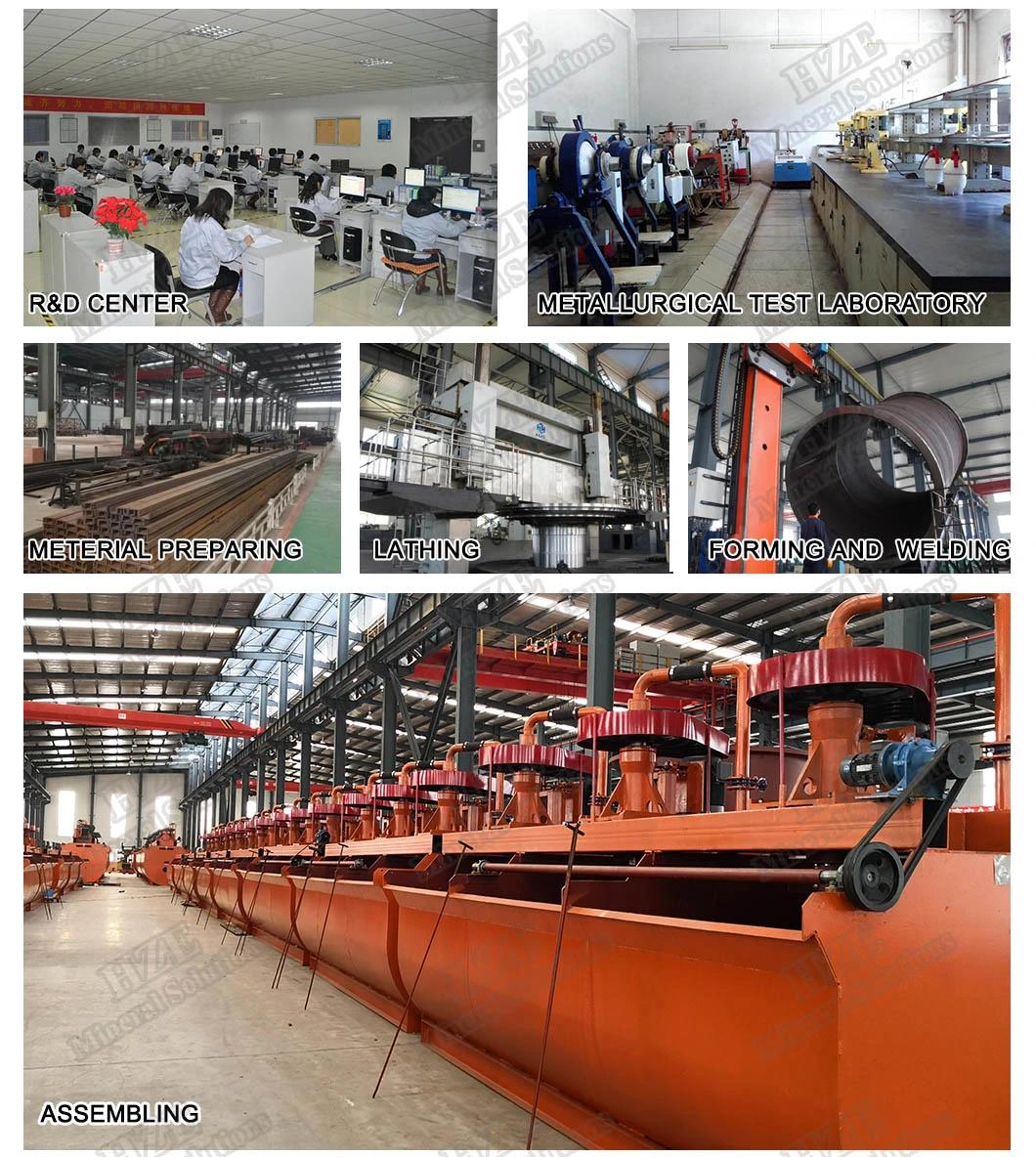

1. What is the main business scope of your company?

HZE is a company with R&D center, design institute, manufacturing factories, installation and commissioning teams. Our customers are in the mining and mineral processing fields. Our major businesses include mineral processing EPC (engineering, procurement and construction), project consultation, engineering design, mineral processing equipment manufacturing, on-site installation, commissioning, staff training, customer project operation management, spare parts supply and technical support. Customers are free to choose any one or any combination of our services.

2. What are the outstanding advantages of your company?

The one-stop service of mineral processing engineering project and equipment is our core competitiveness.

The most important feature that HZE distinguishes itself from other engineering companies, design companies or consulting companies is that we are also an equipment manufacturer with a production plant of 50,000 square meters, and we have complete manufacturing rout and the related equipment.

HZE distinguishes itself from other equipment manufacturers by owning its own R&D center and engineering design institute.

HZE distinguishes itself from many mining machinery enterprises by possessing an expert team with members including not only senior engineers of the company, but also top Chinese technical experts, university professors and researchers.

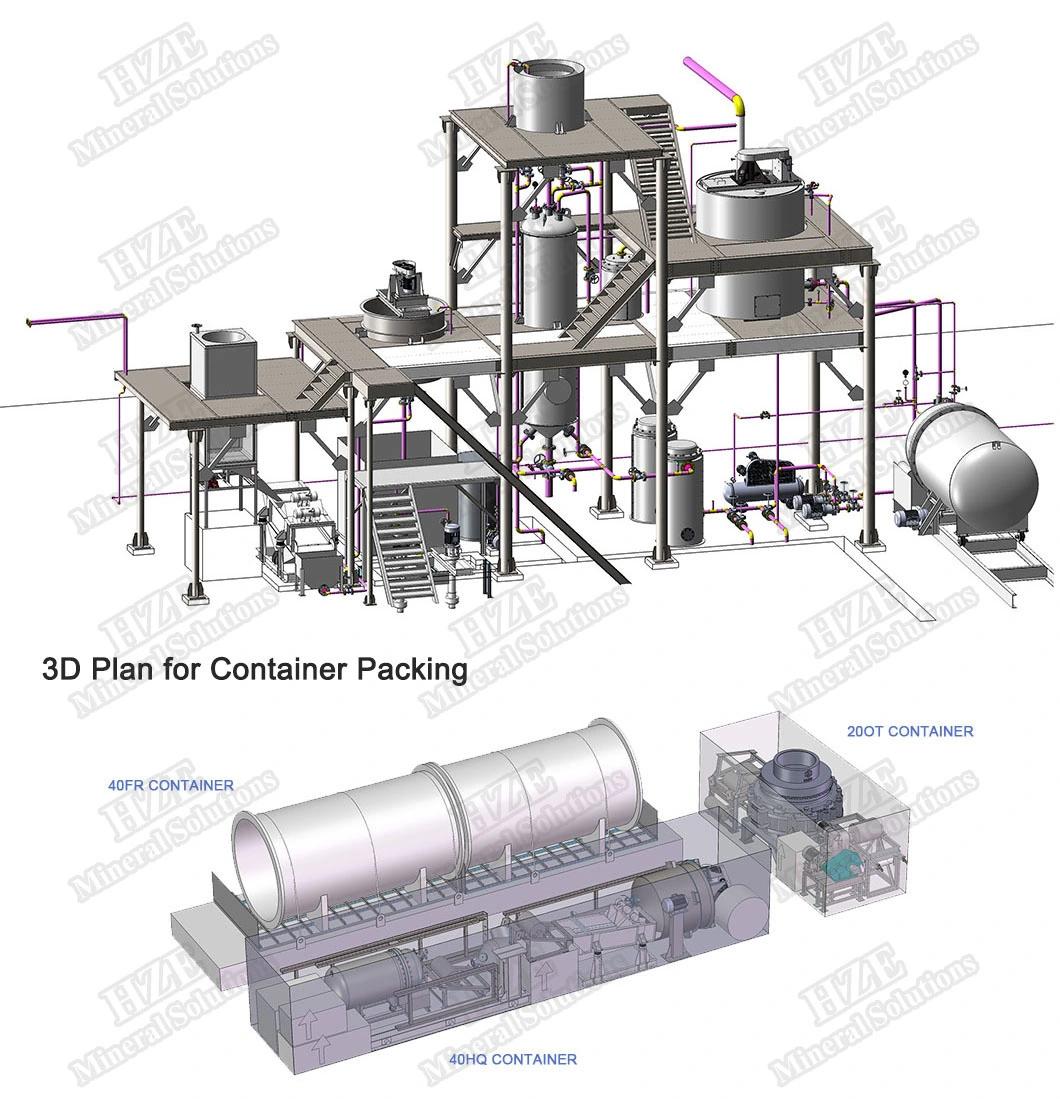

3. What are the characteristics of your company's 3D design?

HZE not only uses 3D software to design equipment, but also uses 3D software to design process flow, pipeline, steel structure, auxiliary facilities, etc. of the whole mineral processing project. We even use 3D design for equipment packaging, container packing and equipment instructions manual. This greatly improves the quality of equipment and engineering, shortens the construction period, facilitates technical discussion and evaluation, facilitates project management, improves construction safety and reduces project cost.

4. What are the service features of your company?

- Customers who whether buy our equipment, or entrust us with EPC, or require us to provide a certain service, cooperate closely with us to carry out specific operations and supervise our implementation throughout the process.

- HZE will try to understand the basic situation and needs of customers as detailed as possible before the sale, formulate a preliminary plan according to the specific situation of customers, and get unanimous opinions after communications and discussions with customers to determine the plan.

- We set up customer files for every customer who signed the contract with us and upload them to the Cloud where customers can also get an account and password. Customers can have all the documents, videos and pictures, technology, services, execution, operation, management and control, maintenance and so on related to the business.

- Whether it is in the process of general contracting, equipment manufacturing or providing some kind of service, we welcome customers to know about our implementation on the spot or through the network, and put forward requirements and opinions.

- We assist users who have used our products to formulate operation specifications and make suggestions on maintenance plans and spare parts inventories. In addition to routine on-site installation, commissioning and training, during the production period after we handing over equipment to customers for use, we often understand the equipment using situations through the network and provide guidance and training to customer management and operators.

- For the clients who have just start the mining business, we provide the opportunity of training and practice in China's mines for the clients' employees, until they are skilled in operation and maintenance.