Mineral Processing Services Metallurgical Test Commissioning Training Technical Support

Yantai Huize Mining Engineering Co., Ltd.- Business Scope:Technical Services

- Customer Field:Mining Industries

- Performance Standard:ISO, GB,T

- Transport Package:Containerized

- Trademark:HZE

- Origin:China

Base Info

- Production Capacity:5 Sets,Year

Description

Basic Info.

Production Capacity 5 Sets/YearProduct Description

Mineral Processing Services Metallurgical Test Commissioning Training Technical Support

HZE provide the client with special technical service for every mineral processing project.

Metallurgical Test

To be certain of the investment in a project, it is clearly needed to know that the mineral processing will work greatly on start-up and throughout the life of the operation. HZE provide the certainty scheme by rigorously testing representative samples and analyzing the results to deliver innovative and cost effective process flowchart and technical indexes that maximize the project's revenue whilst minimizing capital and operating costs.

The metallurgists of HZE are experienced in the comprehensive range of perform bench, pilot and industrial-scale testing using the advanced process equipment and adopting various processing techniques for many sorts of minerals.

The test includes the following items:

(1) Study on the process mineralogy.

(2) Do the elemental analysis for the sample.

(3) Measure the physical properties of the samples such as true specific gravity, bulk density, accumulation angle and hardness of the ore.

(4) Test for ore crushing, grinding, scrubbing and screening analysis.

(5) Design and perform variety of the schemes of separation and recovery. The possible processing involves gravity, magnetic separation, flotation leaching, extraction and so on.

(6) Confirm the mineral processing parameters and the optimized beneficiation flowchart.

(7) Confirm the optimal parameters such as ore particle size required by the processing, magnetic induction intensity, consumption of reagent, PH value, slurry density, leaching residence, recovery ratio.

(8) Carry out the sedimentation test.

(9) Appraise the mineral processing economics.

(10) Submit the finial detailed test report.

Commissioning

HZE provides safe, efficient and timely project commissioning services. Combine the design documents with the actual situations of the customer, formulate detailed commissioning procedures and requirements, thoroughly adjust and test every equipment, facility and processing section of the processing plant to ensure that the capacity and various production and technical indicators meet or exceed the goals identified in design. After the commissioning of the entire project is completed, the commissioning results are confirmed one by one with the customer's management team, and the factory personnel are fully trained, then the plant is delivered.

The main steps of the commissioning include:

No-load Pre-commissioning for Single Equipment→No-load Combined Pre-commissioning→Water Supply Test Running→Air Supply Test Running→HVAC system test Running→Pre-commissioning for Single Equipment with Water→Combined Pre-commissioning with Water→Instrument Test→Commissioning with Load and Materials→Automatic System Commissioning→Reaching the Designed Capacity and Indexes

Training

In order to enable the customer to operate the mineral processing plant smoothly, efficiently and confidently, HZE will fully communicate with the customers to understand the actual situation of the project and the requirements, formulate detailed and thorough training plans, systematically train the customers' employees and evaluates the training results with the managers of the customer together.

The main items of the training include:

Mineral Processing Technology Training

Equipment Operation Training

Post Operation Training

Production Management Training

Maintenance Training

Safety Protection Training

Emergency Handing Training

Technical Transformation of Existing Mineral Processing Plant

Some existing mineral processing plants have serious problems of reducing profits, such as backward technology, unreasonable process combination, low production index, improper matching of production equipment, poor reliability and stability of the production line, low automation level, or the mineral properties have changed a lot but the original technology and production are still used. HZE will arrange the expert team to the site to get a thorough understanding of the actual situation according to the needs of the owner, carry out the necessary metallurgical test, upgrade the technology, improve the design, recommend the high efficiency and reliability equipment, and improve the automation level. The measures are taken to stabilize optimal production index, reduce operation labor intensity, reduce various consumption, improve safety and maximize value.

Technical Research and Development

Specialize in the necessary technical research and development for the actual situation of the owner's project to improve customer value. The content of technical research and development includes develop more adaptable new reagents and design special equipment, which can achieve the best factories matching, application of intelligent mineral processing plant, comprehensive utilization of mineral resources, effective use of water resources, thematic energy saving and consumption reduction, recovery and utilization maximization of refractory minerals, green mining ecological environment renovation and restoration technology, mine environmental protection.

1. What is the main business scope of your company?

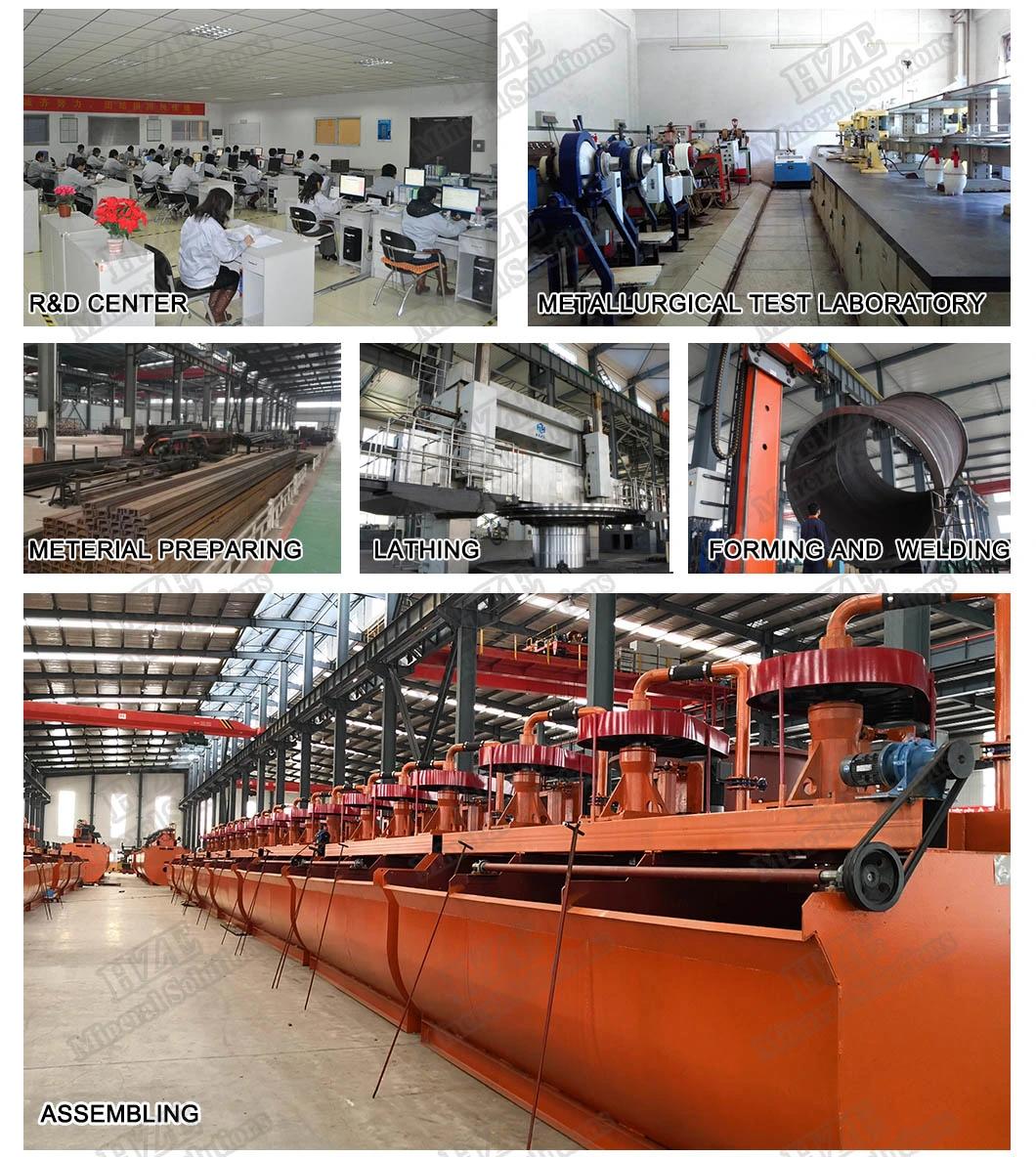

HZE is a company with R&D center, design institute, manufacturing factories, installation and commissioning teams. Our customers are in the mining and mineral processing fields. Our major businesses include mineral processing EPC (engineering, procurement and construction), project consultation, engineering design, mineral processing equipment manufacturing, on-site installation, commissioning, staff training, customer project operation management, spare parts supply and technical support. Customers are free to choose any one or any combination of our services.

2. What are the outstanding advantages of your company?

The one-stop service of mineral processing engineering project and equipment is our core competitiveness.

The most important feature that HZE distinguishes itself from other engineering companies, design companies or consulting companies is that we are also an equipment manufacturer with a production plant of 50,000 square meters, and we have complete manufacturing rout and the related equipment.

HZE distinguishes itself from other equipment manufacturers by owning its own R&D center and engineering design institute.

HZE distinguishes itself from many mining machinery enterprises by possessing an expert team with members including not only senior engineers of the company, but also top Chinese technical experts, university professors and researchers.

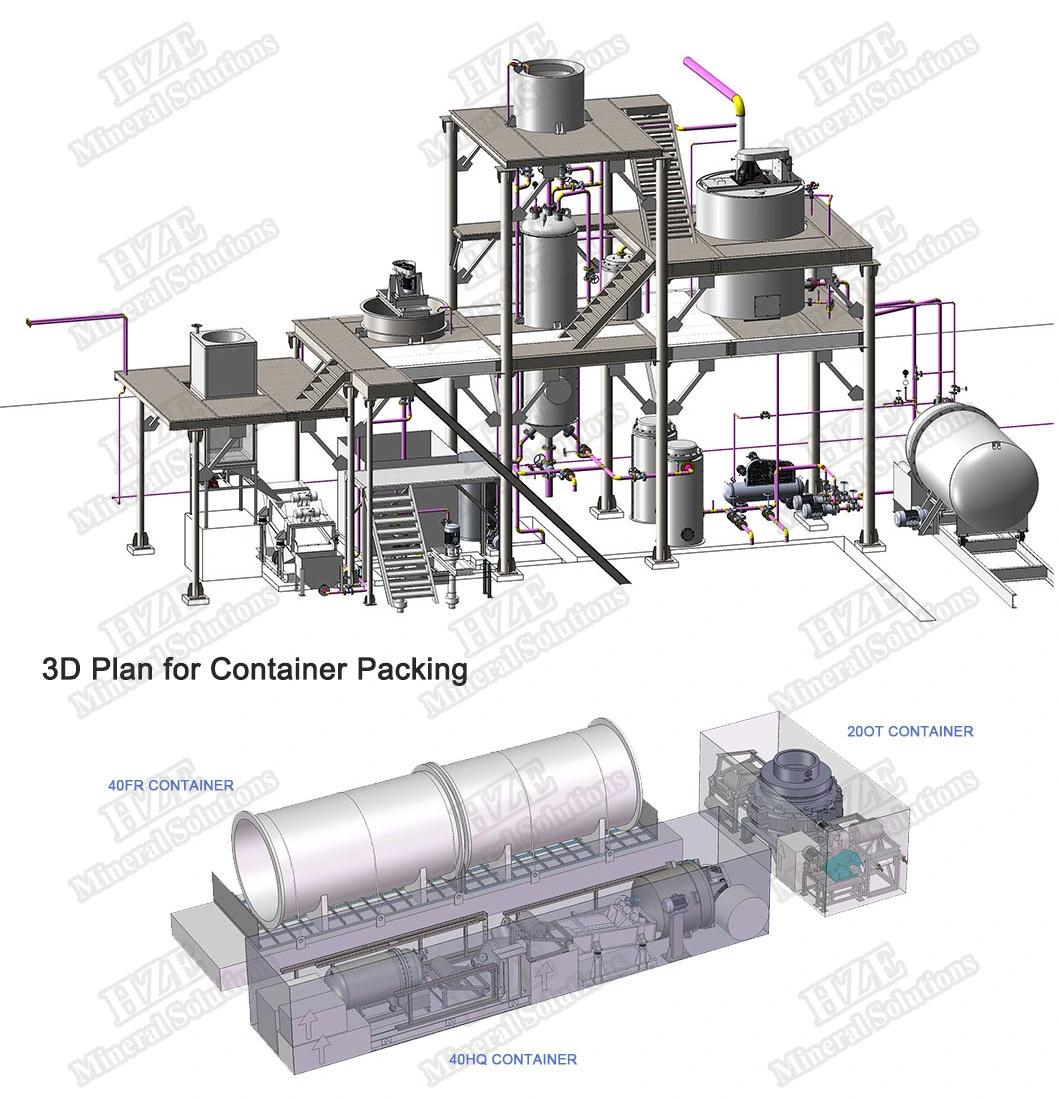

3. What are the characteristics of your company's 3D design?

HZE not only uses 3D software to design equipment, but also uses 3D software to design process flow, pipeline, steel structure, auxiliary facilities, etc. of the whole mineral processing project. We even use 3D design for equipment packaging, container packing and equipment instructions manual. This greatly improves the quality of equipment and engineering, shortens the construction period, facilitates technical discussion and evaluation, facilitates project management, improves construction safety and reduces project cost.

4. What are the service features of your company?

- Customers who whether buy our equipment, or entrust us with EPC, or require us to provide a certain service, cooperate closely with us to carry out specific operations and supervise our implementation throughout the process.

- HZE will try to understand the basic situation and needs of customers as detailed as possible before the sale, formulate a preliminary plan according to the specific situation of customers, and get unanimous opinions after communications and discussions with customers to determine the plan.

- We set up customer files for every customer who signed the contract with us and upload them to the Cloud where customers can also get an account and password. Customers can have all the documents, videos and pictures, technology, services, execution, operation, management and control, maintenance and so on related to the business.

- Whether it is in the process of general contracting, equipment manufacturing or providing some kind of service, we welcome customers to know about our implementation on the spot or through the network, and put forward requirements and opinions.

- We assist users who have used our products to formulate operation specifications and make suggestions on maintenance plans and spare parts inventories. In addition to routine on-site installation, commissioning and training, during the production period after we handing over equipment to customers for use, we often understand the equipment using situations through the network and provide guidance and training to customer management and operators.

- For the clients who have just start the mining business, we provide the opportunity of training and practice in China's mines for the clients' employees, until they are skilled in operation and maintenance.