-

Hyton Manganese Casting Telsmith Cone Crusher Wear Parts Bowl Liners Mantle and Concave

ISO9001Produce Process & QCHYTON supply plenty of mantle models for cone crusher. The material of mantle and bowl liner, we use the high quality manganese, like Mn13Cr2, Mn14Cr2, Mn18Cr2, etc… to ensure the wear resistance. Our cone crusher parts are widely used on mining, construction, ag

Maanshan City Hyton Heavy Industry Technology Development Co., Ltd.

-

Sb43 Sb50 Hydraulic Breaker Attachment Seal Kit for Soosan Excavators

Acorrding to breaker brand or as your request Hebei Monteono Machinery Technology Co.,Ltd., located in Handan city, Hebei Province, is a leading manufacturer of excavator attachments, pipeline kit, seals kit ,hydraulic breaker, breaker chisel, bushingand other excavator spare parts. We have over 10

-

Nice Price! T45 T51 T38 Shank Adapter for Sales

Basic Info. Model NO. T45 T51 T38

-

Manganese Casting Terex Jaw Crusher Spare Parts Fixed / Swing Jaw Plate

CoJaw Crusher PartsCH430HP100GP100S2'CJ208C80NP1213PE250*400CM1208iUJ310CH440HP200GP200S3'CJ209C96NP1313PE400*600CM1208FUJ400iCH660HP300GP300S4'CJ211(J11)C100NP1315PE500*750CM1211UJ440ECH870HP400GP500S4800 4¼ 'CJ408(JM806)C106NP1415PE600*900CM1511UJ540CH880(H8800)HP500GP1005100 5½ 'CJ4

-

Hot Selling High Quality China Factory Reverse Circulation Rock Drilling Bit Re547 for RC ...

Part NomminchGauge ButtonsFront Buttons1365 3/88 x 16mm6x16+3x1435213419.0PR54-1361405 1/28 x 16mm6x16+3x1435213819.3PR54-1401435 5/88 x 16mm6x16+3x1435214119.5PR54-1431465 3/48 x 16mm6x16+3x1435214419.6PR54-146Reverse Circulation Hammer specifications:1) 3" RC hammers: RE531,2) 4'' RC hammers:

-

Suit Sandvik CV228 CV Series Trial Plate VSI Vertical Shaft Impact Crusher Accessories

Basic Info. Model NO. cv228

Maanshan City Hyton Heavy Industry Technology Development Co., Ltd.

-

Adapt to Nordberg Gyratory Crusher Spider Arm Assembly Spider Arm Shield

What Model We HaveHPHP100/HP200/HP300/HP400/HP500/HP700/HP800/HP4/HP5/HP6GPGP100/GP100S/GP200/GP200S/GP300/GP300S/GP500/GP500S/GP550/GP11CH&HCH420/CH430/CH440/CH660/CH870/CH880/H4800/H3800/H6800/H8800CS&SCS420/CS430/CS440/CS660/S3800/S4800/S6800/S8800SYMONS2FT-STD/ 3FT-STD/4FT-STD/4 1/4FT-ST

-

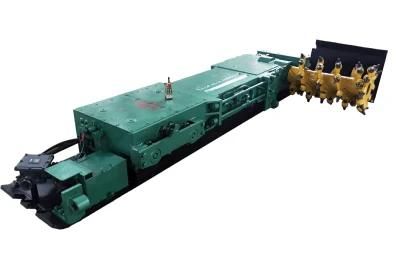

100Manual2005YRG4Manual2011YRG5Manual* remote control2012Thin seam coal cutter MG110-BTYRG60.8-1.5110Manual, manual + remote control2016Extra thin seam coal cutterYRG7<0.570-100Remote controlDuring industrial testMain technical parameters of MG100-TP (YRG4) type coal cutter:Applicable inclined an

-

Hb20g Hb30g F45 F22 F35 F30 Hydraulic Breaker Side Bolt

WELCOME TO INQUIIRY!!!CONTACT ME DIRECTLYThrough bolts and side bolts assemblyWe supply the parts of Hydraulic Breaker, such as cylinder, front head, back head, piston, chisel, accumulator, seal kits, side bolts, through bolts, etc.Spare parts for Hydraulic breaker:1) Reliable quality2) Very competi

-

China Casting Foundry Nordberg HP500 Cone Crusher Spare Parts Main Frame Assembly Assy

What Model We HaveHPHP100/HP200/HP300/HP400/HP500/HP700/HP800/HP4/HP5/HP6GPGP100/GP100S/GP200/GP200S/GP300/GP300S/GP500/GP500S/GP550/GP11SYMONS2FT-STD/ 3FT-STD/4FT-STD/4 1/4FT-STD/5 1/2FT-STD/7FT HD-STD/7FT EHD-STD2FT-SHD/3FT-SHD/4FT-SHD/4 1/4FT-SHD/5 1/2 FT-SHD/7FT HD-SHD/7FT EHD-SHDMain Features1.