Mining Wire Screen Mesh Crimped Wire Mesh/Woven Screen Mesh/Vibrating Screen Mesh Used in ...

Baytain Rubber and Plastic Products Co., Ltd.- Certification:CE, RoHS, ISO 9001:2000, ISO 9001:2008

- Standard:AISI, ASME, BS, ANSI, JIS, GOST, ASTM

- Surface Treatment:Sand Blast

- Manufacturing Process:Stamping

- Material:Rubber

- Transport Package:Pallet

Base Info

- Model NO.:003

- Specification:customized

- Trademark:BT

- Origin:China

- HS Code:3901200090

- Production Capacity:100000 Units Per Year

Description

Basic Info.

Model NO. 003 Specification customized Trademark BT Origin China HS Code 3901200090 Production Capacity 100000 Units Per YearProduct Description

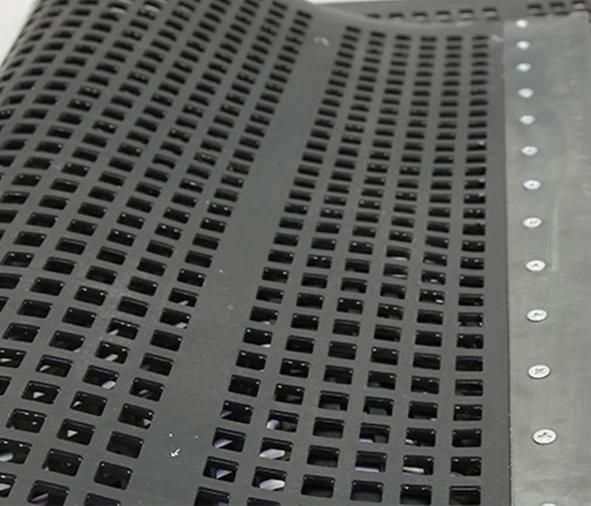

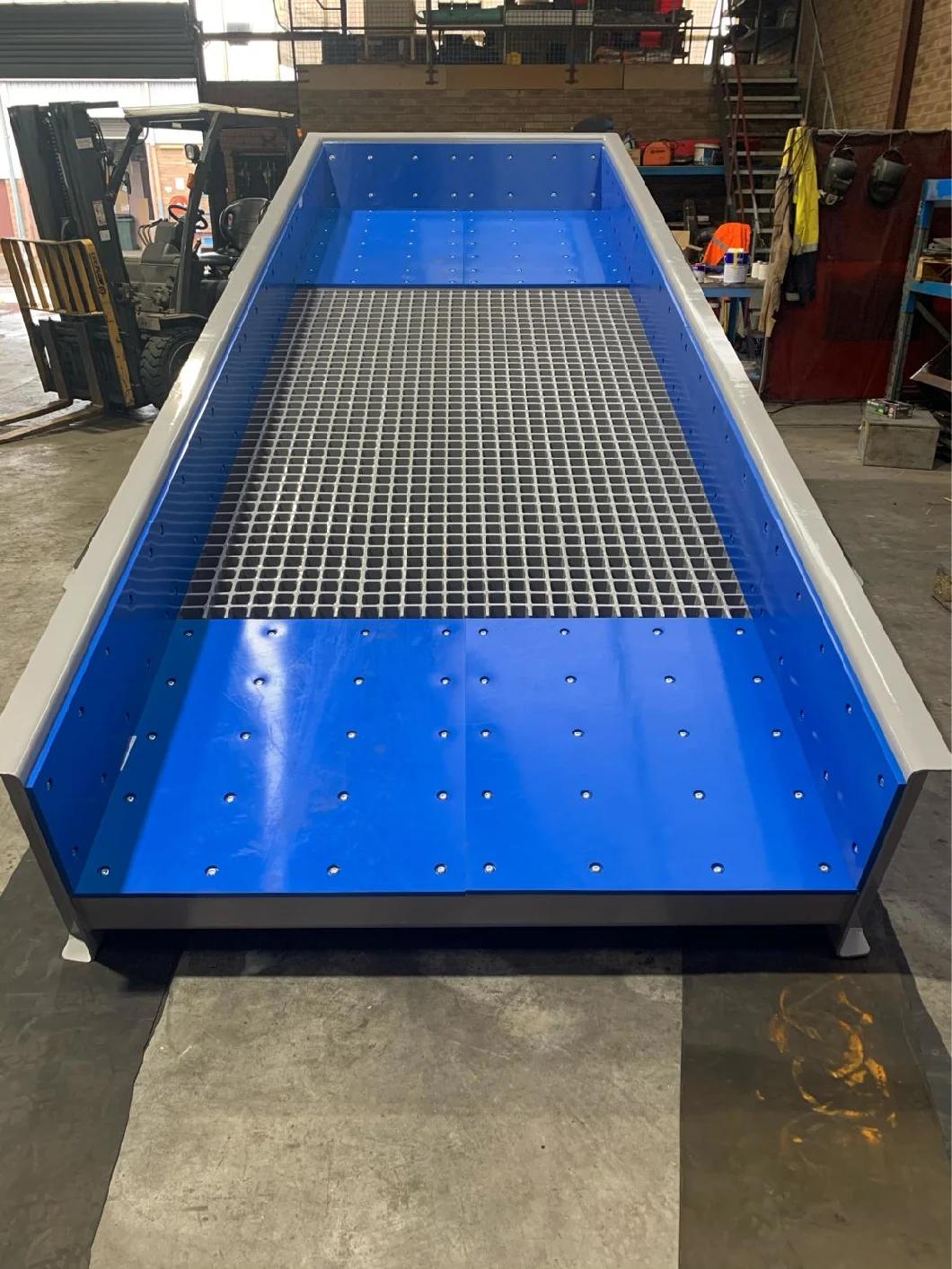

Rubber cross tension screen mesh is best suited for medium coarse to fine screening applications. The use of rubber will reduce noise, reduce blockage and offer exceptional wear capabilities. Screen rubber cross tension mats are manufactured using 2 layers of premium quality wear resistant rubber with a cord reinforcement between the layers.Thinner cloths (3, 5, 7, 10 & 15mm thick) have single ply fabric reinforcement while 20, 25 & 35mm thick cloths have 2 layers. The polyester fabric reinforcement allows for correct and constant tensioning of the cloth.

Advantages:

Some of the advantages that Rubber Tension Mats have over other screening media include:

- Fit most manufacturers' screens

- Highly flexible - reduced pegging & blinding

- Highly flexible - improved stratification

- Reduces noise pollution

- Suitable for a wide variety of applications

* Please note: All cross tension products can be converted to modular if desired.

Range of Screenex Rubber:

PD40 (40 durometer)

Softer rubber with high flexibility to solve the toughest blinding problems. PD40 rubber can be used between -40° C (-40° F) and 70° C (150° F). See our Flexi Rubber panel.

PD65 (65 durometer)

Hard rubber that is best for High impact applications like scalping or heavy feed rates. PD65 rubber can be used between -50° C (-60° F) and 70° C (150° F).