Bucket Type Wheel Sand Washer for Sand Making and Washing Plant

Henan Yuhui Mining Machinery Co., Ltd.- Type:Spiral Sand Washer

- Capacity:According to The Model

- Water Consumption:According to The Model

- Speed of Screw:21rpm

- Motor Type:AC Motor

- Motor Power:3-15kw

Base Info

- Model NO.:many models

- Certification:ISO

- Rotation Speed:0.8-1.5 r,min

- Wheel Bucket Diameter:According to The Model

- Screw Diameter:According to The Model

- Product Name:Bucket Wheel Sand Washer

- Return Sand Capacity:3-200t,H

- Application:Sand Stone Production Line

- Transport Package:Loaded Into Container

- Specification:according to the model

- Trademark:Yuhui

- Origin:China

- HS Code:8474

- Production Capacity:50 Sets Per Month

Description

Basic Info.

Model NO. many models Certification ISO Rotation Speed 0.8-1.5 r/min Wheel Bucket Diameter According to The Model Screw Diameter According to The Model Product Name Bucket Wheel Sand Washer Return Sand Capacity 3-200t/H Application Sand Stone Production Line Transport Package Loaded Into Container Specification according to the model Trademark Yuhui Origin China HS Code 8474 Production Capacity 50 Sets Per MonthProduct Description

Bucket type wheel sand washer for sand making and washing plant

Sand washer application:

Sand washer is applied for washing applications in sand plant, mine, concrete batching plant, and industries like building materials production, transportation, chemistry, water conservancy, etc. Our sand washing machine is a highly efficient machine designed on the basis of the detailed washing needs in mining industry and comes with features like good washing effect, reasonable structure, large capacity, and less sand loss during washing process. The transmission part of this sand washing machine is isolated from water and sand, which could greatly reduce the error rate of the machine.

Working principle of sand washer:

The electric motor runs slowly with the impellor after decelerated by the belt, decelerator and gears wheel. The sand and stone flow into washing launder from feeding launder, rolls with the impellor, and grinds each other. The impurity covering the sand is washing away. At the same time, add more water, the strong water flow will take away waste and some low-weight wastes from washing launder. On one hand, water is removed from the sand and stone; on the other hand, the water can be fully used. Finally, the sand and stone goes to the out launder from the rotary impellor to finished. Then clean sand and stone is lift up by vane. When it goes up slowly, the water begins to drop through the mesh and fall back in the washing launder. Finally, the sand and stone goes to the out launder from the rotary impellor to finish the washing task.

Features of sand washer:

1. High efficiency, reasonable structure, high capacity and low consumption

2. The bearing device of impeller drive is separated from water and materials in water, which greatly protects the bearing from soaking, sand and pollutants.

3. Compared with the spiral sand washing machine, the loss of medium and fine sand and powder is minimized, and the grade and fineness can meet the required standard

4. This machine is with long service life and low maintenance costs.

Technical parameters:

| model | Process load (t/h) | Return sand load (t/h) | Power (kw) | Weight (kg) |

| GX2000 | 8-40 | 3-8 | 4 | 1900 |

| GX2600 | 20-100 | 5-15 | 5.5 | 3500 |

| GX2800 | 50-130 | 8-70 | 7.5 | 5100 |

| GX3200 | 240-300 | 80-130 | 11 | 8800 |

| GX3600 | 280-500 | 100-200 | 15 | 14200 |

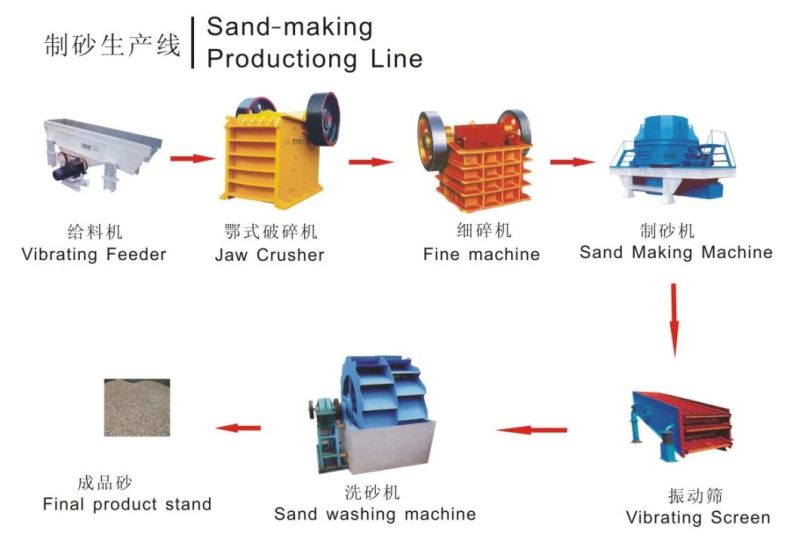

Other related products for sand making production line:

About our company:

Henan Yuhui Mining Machinery Co, Ltd. is located in Zhengzhou city in central plains, which adjoins to ancient millennium Shaolin Temple (Kung fu Origin) to the south, and Yellow River to the north. With Kailuo highway and Longhai railway, it owns convenient transportation and pleasant scenery.

Established in the 1970s, Henan Yuhui Mining Machinery Co.,Ltd. has developed into a famous manufacturer through 20 years struggling and progressing, specialized in producing mineral dressing equipment, compound fertilizer equipment, cement equipment, as well as sand making equipment.

YuHui provides a connected sequence service with designing process flow, on-site civil engineering guidance, installing and debugging the equipment, training technical and operating people for clients. The company guarantees repair, replacement and refund and is warrantable to the complete machine for one year. It supplies accessories for a long period. Welcome inquiries and purchase from both new and old customers as well as worldwide friends.

Our customers:

Each year we have the customers from world wide to our company for visit, like America, Malaysia, Indonesia, Philiphine, Sudan, Namibia, Zimbabwe, Zambia, Ethiopia, india, peru and so on.

Welcome to our company for visit.

Q1. Is your company a manufacturing company and do you have a company certificate?

A: Yes, our company is a manufacturing company and we are specialized in mining machinery for more than 40 years with two factories. Our company has owned the certificate of ISO9001:2000.

Q2. Where are your products mainly exported?

A: Our products are distributed throughout the world, being involved in more than Asia, Africa, South America regions. And our products win the good reputation of the foreign customers.

Q3. What's the additional features of your company?

A: We have our own laboratory in the company. So the clients can take some samples to perform experiments on the spot. And our engineers will provide the best advice and choice for our clients.

Q4. Welcome to our company.

A: We have stone product line, sand-making product line and so on. The clients can visit our production site.

Q5. How do you guarantee your after service?

A: Our company guarantees repair, replacement and refund and it is warrantable to the complete machine for 12 months. And we can design the site for free and provide basic materials, assembly drawings and equipment installation technical services. At the same time, we provide a connected sequence services with directing civil engineering on spot, installing and debugging the equipment, training technical and operating people abroad. Also, our engineers are assured be sent to work broad for a long period. Our company supplies accessories for a long period and lifetime warranty.