High Efficiency Mini Quartz Grinding Ceramic Wet Ball Mill Machine

Henan Centbro Machinery Equipment Co., Ltd.- Type:Ball Mill

- Motor Type:AC Motor

- Motor Power:55kw

- Rotationl Speed:32.4r,Min

- Application:Chemistry

- Materials:Molybdenum

Base Info

- Model NO.:1200*4500

- Condition:New

- Warranty:One Year

- After-sales Service:Engineer Workinf on The Site

- Weight:13.8t

- Output:1.6-5.8t,H

- Feed-in Material Size:<25

- Feed-out Material Size:0.074-0.4mm

- Ball Load:5t

- Transport Package:Eporting Standard

- Specification:Please see the details

- Trademark:STM Centbro

- Origin:Zhengzhou, China

- HS Code:8474202000

- Production Capacity:20 Sets Per Month

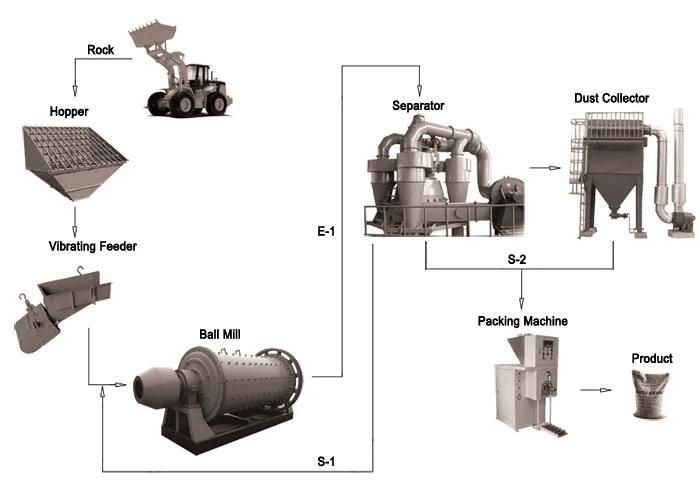

Description

Product Details

Benefits Features

1. Large application range, simple structure and convenient maintenance;

2. Large capacity and continuous work are obvious advantages;

3. Various barrel lining and grinding media, excellent corrosion resistance;

4. Installation and adjustment are very convenient and easy to operate.

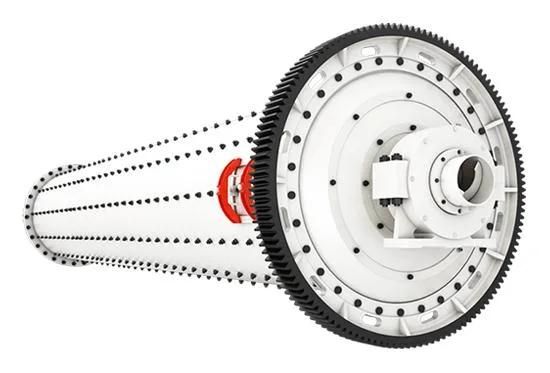

5.Cylinder is rolled and welded with Q235B steel plate. (the steel thickness is generally 1/100 of the cylinder diameter, for example ball mill of Φ1500, the steel plate thickness is 16 mm), the material of inlet and outlet hollow shaft is ZG35.

6. The hollow axis adopts the cast steel and the lining can replace, the rotating big gear processes in the way of casting rolling gear. The barrel body is wearable well and bears wearable scaleboard. This machine run steadily and works reliably.

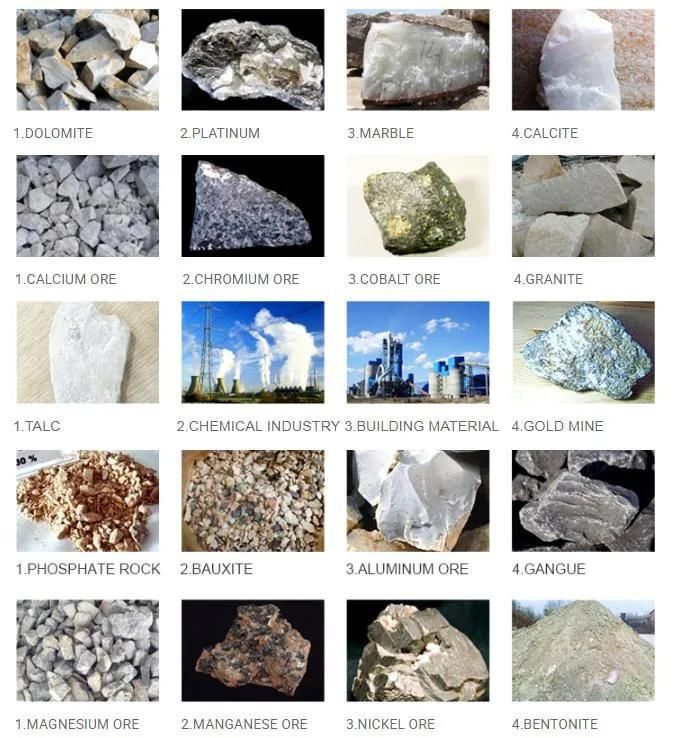

This type of machine are widely used in mineral , metallurgy, chemical industry, building materials, coal, matallugrge, powder with material mositure under 8% and hardness below 8 class. The finess of the final products can be adjusted during the range from feldspar, calcite, limestone, dolomite, graphite, gold and silver ore, rutile, aluminum, titanium dioxide, kaolin, bentonite, flint clay, fluorite, wollastoniteore, phosphate rock, silicon metal, electrolytic fierce, coking, corundum, silicon smelting, calcic magnestie mine, coal, actiated carbon, plant ash, coal gangue, slag, ziron sand, iron ore, potash feldspar, talc, granite, marble, barite, wax, feldspar, clay, glass, coke, pet coke, fly ash, yanliu, clay ceremsite sand, salt mud, sand, additives, curing agent, waste, waste brick of pottery and porcelain and refactory materials.

This type of machine are widely used in mineral , metallurgy, chemical industry, building materials, coal, matallugrge, powder with material mositure under 8% and hardness below 8 class. The finess of the final products can be adjusted during the range from feldspar, calcite, limestone, dolomite, graphite, gold and silver ore, rutile, aluminum, titanium dioxide, kaolin, bentonite, flint clay, fluorite, wollastoniteore, phosphate rock, silicon metal, electrolytic fierce, coking, corundum, silicon smelting, calcic magnestie mine, coal, actiated carbon, plant ash, coal gangue, slag, ziron sand, iron ore, potash feldspar, talc, granite, marble, barite, wax, feldspar, clay, glass, coke, pet coke, fly ash, yanliu, clay ceremsite sand, salt mud, sand, additives, curing agent, waste, waste brick of pottery and porcelain and refactory materials.

Certificates:

Certificates:

Support:

Support:We can not only provide the good machines, but also wholeheartedly provide the comprehensive for our clients. The series of professional technology service will make you have an excellent product experience.

After-sales service support :

After we signed the purchase contract and have a certain reputation guarantee, we will contact the professional group that responsible for ship bookings, commodity inspection, commercial invoices, packing list, insurance policy and so on, in order to provide you the perfect goods trading services, until the product you purchased properly to your hands.

We will send a professional and high levels installation engineer team at the same time the product properly to the destination, in order to supply you a full range of products installation services. For some typical problems, our rigorous installed engineers also will do some certain installation debugging training, etc.

Technological support :

STM Group has been largely adopting new technologies, new techniques and high-tech equipment. And STM Group also has strict and effective quality control system. We have obtained ISO9001:2000, TUV and CEquality system certificate.

Contact: