Gold Powder Making Machine Grinding Equipment Ball Mill for Limestone Marble Powder ...

Shanghai Clirik Machinery Co., Ltd.- Type:Ball Mill

- Motor Type:AC Motor

- Motor Power:18.5KW

- Rotationl Speed:23-25r,min

- Application:Mining,Quarry,Chemical Industry and Construction

- Materials:Cement, Minerals, etc

Base Info

- Model NO.:Ball Mill

- Condition:New

- Warranty:1 Year

- After-sales Service:Technical Support

- Cement Ball Mill Warranty:12 Months

- Cement Ball Mill Fineness:30-400 Mesh

- Cement Ball Mill After Sales Service:The Whole Time

- Cement Ball Mill Spare Parts Supply:Will Supply Any Time

- The Machines Classification:Ball Mill Grinding

- Cement Ball Mill Capacity:20-200 T,H

- Cement Ball Mill Test&Installation:Professional Engineer Assigned

- Cement Ball Mill Mining Object:Cement Ball Mill

- Cement Ball Mill Port:Shanghai

- Cement Ball Mill Weight:1.5-65

- Transport Package:Export Standard

- Specification:CE

- Trademark:Clirik

- Origin:China

- HS Code:84742090

- Production Capacity:10-128 Tph

Description

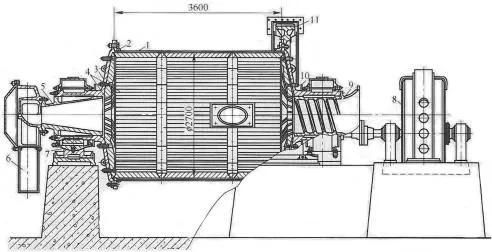

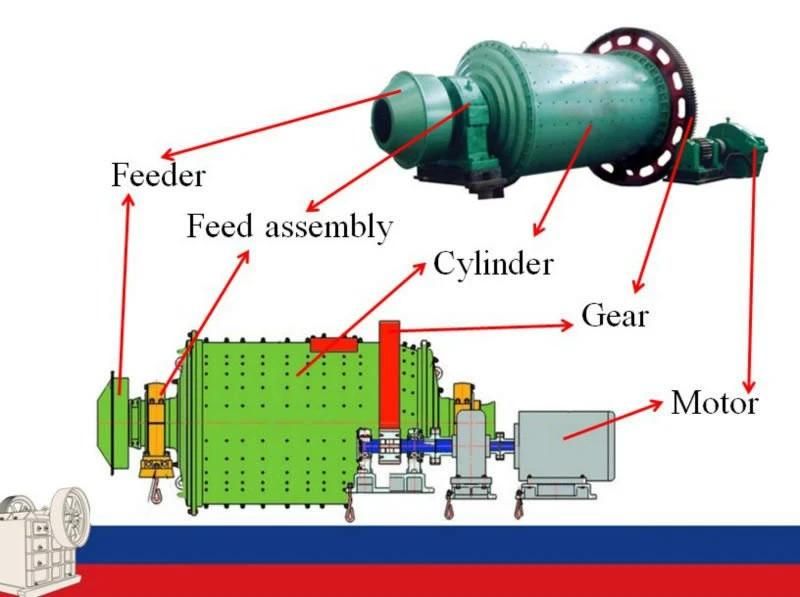

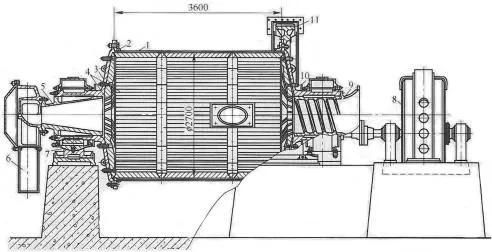

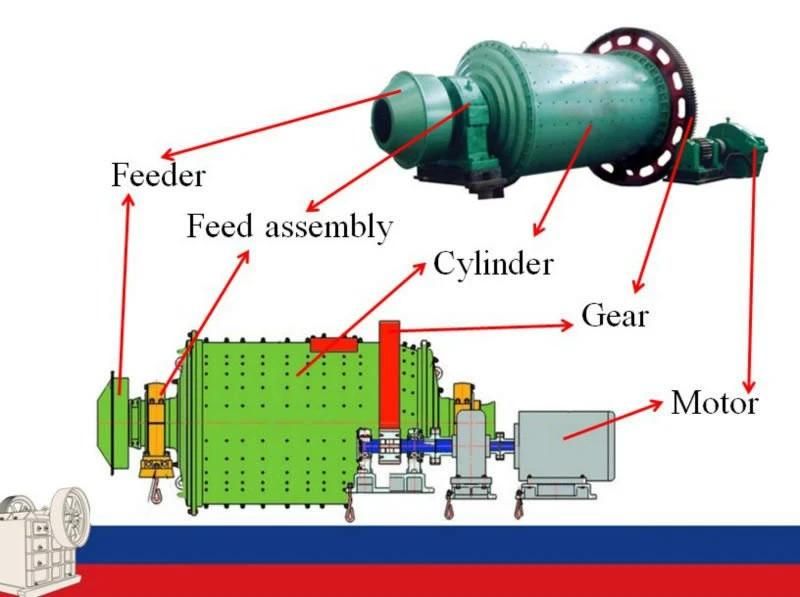

Cement Production Line, Cement Production Process, Cement Ball Mill working principle:

The Cement Production Line, Cement Production Process, Cement Production Plant is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.

Cement Production Line, Cement Production Process, Cement Ball Mill features&advantages:

1. High production capacity and crushing ratio.

2. Low power consumption, uniform particle size.

3. Simple structure, easy to operate.

4. Low investment cost, big profit.

5. Perfect services, both before-sales servies and after-sales services.

Cement Production Line, Cement Production Process, Cement Production Plant sales worldwide

Cement Production Line, Cement Production Process, Cement Production Plant Packing & Shipping

Packing: Conventional Packaging suitable for long distance transportation.

Shipping: 10-30 working days after recieving the deposit of the devices.

Pre-sale service:

1.Clirik provides a variety of mining equipment for you to choose from.

2.Clirik will recommend suitable production lines and grinding equipment to you according to your site.

3.Clirik customizes the logo and color of the grinding equipment according to your company image.

4.Clirik provides third party inspection to ensure the quality of your grinding equipment.

After-sales service:

1. Clirik provides you with online installation and use videos.

2. Clirik will provide you with technicians to install and debug the grinding equipment.

3. Clirik trains you the technicians who use and maintain the grinding equipment.

4. Clirik provides you with a one-year warranty and lifetime service for the grinding equipment.

Our certificate

FAQ

1. What advantages does your Cement Production Line, Cement Production Process, Cement Ball Mill have?

The main advantage of our Cement Production Line, Cement Production Process, Cement Production Plant over other kinds of mills is that you can grind a friable or crystalline material to fine average particle size and classify in a very narrow particle size range at the same time.

2. What particle size range does your Cement Production Line, Cement Production Process, Cement Ball Mill produce?

Typically the Clirik Cement Production Line, Cement Production Process, Cement Ball Mill will grind friable or crystalline materials down to the 0.075 -0.4/0.89 mm average particle size range. Particles larger than 10 microns are generally hard-to-fracture polymers such as toner compounds or hard waxes, and some organic materials, but if a larger size is wanted, many products can be ground larger than 10 microns by reducing power to the mill or by increasing the rate of feed. Some products are simply polished to remove sharp edges by running at elevated feed rates with low grinding pressure, a process that changes how the material compacts

The Cement Production Line, Cement Production Process, Cement Production Plant is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.

Cement Production Line, Cement Production Process, Cement Ball Mill features&advantages:

1. High production capacity and crushing ratio.

2. Low power consumption, uniform particle size.

3. Simple structure, easy to operate.

4. Low investment cost, big profit.

5. Perfect services, both before-sales servies and after-sales services.

Cement Production Line, Cement Production Process, Cement Production Plant sales worldwide

Cement Production Line, Cement Production Process, Cement Production Plant Packing & Shipping

Packing: Conventional Packaging suitable for long distance transportation.

Shipping: 10-30 working days after recieving the deposit of the devices.

Pre-sale service:

1.Clirik provides a variety of mining equipment for you to choose from.

2.Clirik will recommend suitable production lines and grinding equipment to you according to your site.

3.Clirik customizes the logo and color of the grinding equipment according to your company image.

4.Clirik provides third party inspection to ensure the quality of your grinding equipment.

After-sales service:

1. Clirik provides you with online installation and use videos.

2. Clirik will provide you with technicians to install and debug the grinding equipment.

3. Clirik trains you the technicians who use and maintain the grinding equipment.

4. Clirik provides you with a one-year warranty and lifetime service for the grinding equipment.

Our certificate

FAQ

1. What advantages does your Cement Production Line, Cement Production Process, Cement Ball Mill have?

The main advantage of our Cement Production Line, Cement Production Process, Cement Production Plant over other kinds of mills is that you can grind a friable or crystalline material to fine average particle size and classify in a very narrow particle size range at the same time.

2. What particle size range does your Cement Production Line, Cement Production Process, Cement Ball Mill produce?

Typically the Clirik Cement Production Line, Cement Production Process, Cement Ball Mill will grind friable or crystalline materials down to the 0.075 -0.4/0.89 mm average particle size range. Particles larger than 10 microns are generally hard-to-fracture polymers such as toner compounds or hard waxes, and some organic materials, but if a larger size is wanted, many products can be ground larger than 10 microns by reducing power to the mill or by increasing the rate of feed. Some products are simply polished to remove sharp edges by running at elevated feed rates with low grinding pressure, a process that changes how the material compacts