Slon Silica Sand/ Quartz/ Mica Purification Wet High Intensity Magnetic Mineral Separator ...

SLon Magnetic Separator Co., Ltd.- Type:Magnetic Separator

- Voltage:Customized

- Weight:>10T

- Material:Stainless Steel

- Material Feature:Conductivity

- Certification:CE, ISO9001:2015

Base Info

- Model NO.:SLon-2000

- Energy Saving:Energy Saving

- Warranty:1 Year

- Color:Multi Color

- Customized:Customized

- Condition:New

- After-sales Service:Lifetime

- Capacity:50~80t,H

- Ore-Feeding Size:-1.3mm

- Ore-Feeding Concentration:10%~40%

- Water Consumption:80~120m3,H

- Magnetic Field Strength:0.4~1.8t

- Installation:Site Installation

- After-Sale Service:Lifetime

- Transport Package:Seaworthy Packing

- Specification:SLon-2000

- Trademark:SLon

- Origin:China

- HS Code:8474100000

- Production Capacity:20sets,Month

Description

SLon WHIMS for Non-metallic MineralsParameters SLon-2000 SLon-2000 SLon-2000 SLon-2000 SLon-2000 SLon-2000 Ring diameter /mm 2000 2000 2000 2000 2000 2000 Ring speed /(r/min) 2.5~3.5 2.5~3.5 2.5~3.5 2.5~3.5 2.5~3.5 2.5~3.5 Feed size /(mm),(-74μm%) -1.3(30~100) -1.3(30~100) -1.3(30~100) -1.3(30~100) -1.3(30~100) -1.3(30~100) Feed density/% 10~40 10~40 10~40 10~40 10~40 10~40 Slurry throughput /(m3/h) 100~200 100~200 100~200 100~200 100~200 100~200 Ore throughput /(t/h) 25~80 25~80 25~40 25~40 25~40 20~35 Background field /T 0.4 0.7 1/1.1 1.3 1.5 1.8 Rated current /A 950 1230 1100 1200 1300 2260 Rated voltage /V 16 28 39 50 75 59 Rated power /kW 15 35 43 60 98 133 Ring motor /kW 3 4 5.5 5.5 5.5 5.5 Water pressure /MPa 0.2~0.4 0.2~0.4 0.2~0.4 0.2~0.4 0.2~0.4 0.2~0.4 Flushing water consumption/(m3/h) 80~120 80~120 80~120 80~120 80~120 70~120 Cooling water consumption /(m3/h) 2~3 2.5~3.5 3~4 4~5 5~6 6~7 Max part weight /t 7 9 14 16 17 18 Dimensions (L*W*H) /mm 2680×3000×3950 2700×3150×4050 2780×3460×4200 2610×3900×4450 2680×3860×4600 2700×3700×4500 Parameters SLon-2000 SLon-2000 SLon-2000 SLon-2000 SLon-2000 SLon-2000 Ring diameter /mm 2000 2000 2000 2000 2000 2000 Ring speed /(r/min) 2.5~3.5 2.5~3.5 2.5~3.5 2.5~3.5 2.5~3.5 2.5~3.5 Feed size /(mm),(-74μm%) -1.3(30~100) -1.3(30~100) -1.3(30~100) -1.3(30~100) -1.3(30~100) -1.3(30~100) Feed density /% 10~40 10~40 10~40 10~40 10~40 10~40 Slurry throughput /(m3/h) 100~200 100~200 100~200 100~200 100~200 100~200 Ore throughput /(t/h) 50~80 50~80 50~80 50~80 50~80 40~65 Background field /T 0.4 0.7 1/1.1 1.3 1.5 1.8 Rated current /A 950 1230 1100 1200 1300 2260 Rated voltage /V 16 28 39 50 75 59 Rated power /kW 15 35 43 60 98 133 Ring motor /kW 3 4 5.5 5.5 5.5 5.5 Pulsating motor /kW 7.5 7.5 7.5 7.5 7.5 4 Pulsating stroke /mm 0~26 0~26 0~26 0~26 0~26 0~30 Pulsating speed /(per/min) 0~300 0~300 0~300 0~300 0~300 0~300 Water pressure /MPa 0.2~0.4 0.2~0.4 0.2~0.4 0.2~0.4 0.2~0.4 0.2~0.4 Flushing water consumption /(m3/h) 80~120 80~120 80~120 80~120 80~120 70~120 Cooling water consumption /(m3/h) 2~3 2.5~3.5 3~4 4~5 5~6 6~7 Max part weight /t 7 9 14 16 17 18 Dimensions (L*W*H) /mm 4350×3000×3950 4350×3150×4050 4400×3460×4200 4300×3900×4450 4300×3860×4600 4300×3700×4500

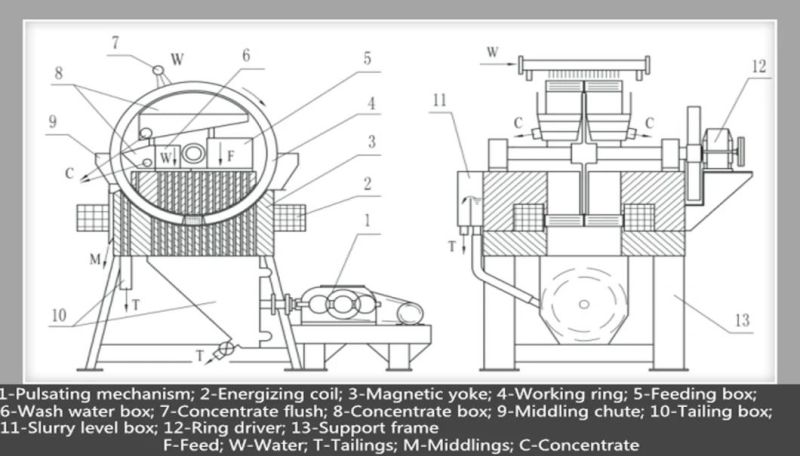

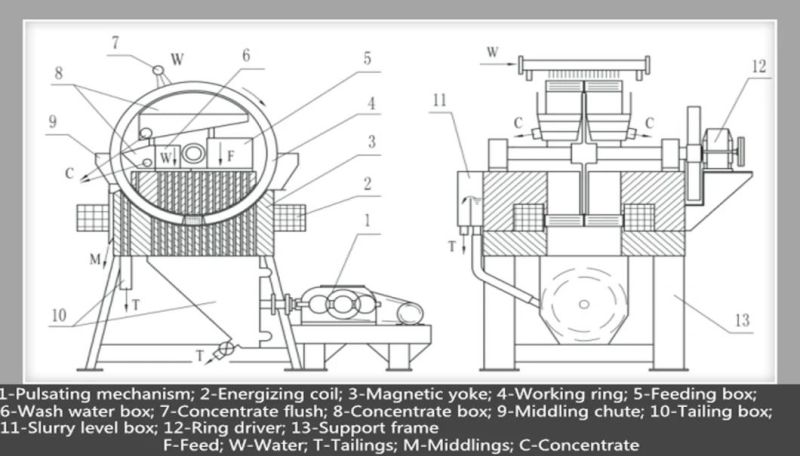

Working Principle:

SLon VPHGMS mainly consists of the energizing coil, magnetic yoke, separating ring, feed and product boxes as shown in Figure. Expanded nets or round bars made of magnetic conductive stainless steel are used as matrix. While a direct electric current follows through the energizing coil, a magnetic field is built up in the separating zone. The ring with matrix rotates clockwise. Slurry from the feed box enters into matrix piles located in the separating zone. Magnetic particles are attracted from slurry onto the surface of the matrix, brought to the top of the ring where magnetic field is negligible, then flushed out into the concentrate box. Non-magnetic particles pass through the matrix and enter the tailing box under the combined force action of slurry pulsation, gravity, and hydrodynamic drag.

As the ring rotates vertically, flushing direction of mags is opposite to that of feed relative to each matrix pile, coarse particles can be flushed out without having to pass through the entire depth of matrix pile. The pulsating mechanism drives slurry in the separating zone up and down, keeping the particles the matrix pile in loose state, so that magnetic particle can be more easily captured by the matrix and nonmagnetic particles can be more easily dragged to the tailing box through the matrix pile. Obviously, opposite flushing and pulsation help to prevent matrix clogging, and pulsating helps to purity magnetic product.

Successful Cases

Being the leader in the industry, SLon's magnetic separator equipment has been widely applied in the field of metallic and non-metallic minerals. Its tracks cover more than 20 countries and regions, including America, Canada, Brazil, Peru, Russia, Korea, India, Iran, Thailand, Philippines, Australia, Sierra Leone and so on. With market holdings of over 4000 machines, SLon has been the largest supplier of magnetic separation equipment in the industry.

Certificates&Patents

SLon always believes that technology is the root of one company. Otherwise, we would risk being an outcast of society with constant change. Therefore, in the past 30 years, SLon has been dedicated to the cutting-edge technology of magnetic separation. Up to now, SLon has been granted 22 invention patents, 39 utility model patents, 4 software copyrights and 65 intellectual property rights in total. At present, there are still 10 patents under substantive examination. It's our commission to introduce the most advanced products and take the lead in the field of electromagnetism.

Package&Delivery

SLon has engaged in export business for over 20 years. We can deal with most of unforeseen circumstances during transportation. Our packages strictly comply with international standards, which ensures that the products are in good condition when you receive them.

Our Service

SLon aims at "100% product qualification, 100% contract performance, 98% equipment operation, 100% customer satisfaction, and zero customer complaint". To achieve the goal, it has established an advanced quality management system integrating experiment, technological process advice, customized product, installation and commissioning, remote instruction, and regular visit. Whenever and Wherever the magnetic separator equipment goes wrong, its professional team will be sent to your plants as soon as possible. It's high quality and excellent service that SLon persists in.

Experiment Photos

Exhibition Photos

Exhibition Photos

Working Principle:

SLon VPHGMS mainly consists of the energizing coil, magnetic yoke, separating ring, feed and product boxes as shown in Figure. Expanded nets or round bars made of magnetic conductive stainless steel are used as matrix. While a direct electric current follows through the energizing coil, a magnetic field is built up in the separating zone. The ring with matrix rotates clockwise. Slurry from the feed box enters into matrix piles located in the separating zone. Magnetic particles are attracted from slurry onto the surface of the matrix, brought to the top of the ring where magnetic field is negligible, then flushed out into the concentrate box. Non-magnetic particles pass through the matrix and enter the tailing box under the combined force action of slurry pulsation, gravity, and hydrodynamic drag.

As the ring rotates vertically, flushing direction of mags is opposite to that of feed relative to each matrix pile, coarse particles can be flushed out without having to pass through the entire depth of matrix pile. The pulsating mechanism drives slurry in the separating zone up and down, keeping the particles the matrix pile in loose state, so that magnetic particle can be more easily captured by the matrix and nonmagnetic particles can be more easily dragged to the tailing box through the matrix pile. Obviously, opposite flushing and pulsation help to prevent matrix clogging, and pulsating helps to purity magnetic product.

Successful Cases

Being the leader in the industry, SLon's magnetic separator equipment has been widely applied in the field of metallic and non-metallic minerals. Its tracks cover more than 20 countries and regions, including America, Canada, Brazil, Peru, Russia, Korea, India, Iran, Thailand, Philippines, Australia, Sierra Leone and so on. With market holdings of over 4000 machines, SLon has been the largest supplier of magnetic separation equipment in the industry.

Certificates&Patents

SLon always believes that technology is the root of one company. Otherwise, we would risk being an outcast of society with constant change. Therefore, in the past 30 years, SLon has been dedicated to the cutting-edge technology of magnetic separation. Up to now, SLon has been granted 22 invention patents, 39 utility model patents, 4 software copyrights and 65 intellectual property rights in total. At present, there are still 10 patents under substantive examination. It's our commission to introduce the most advanced products and take the lead in the field of electromagnetism.

Package&Delivery

SLon has engaged in export business for over 20 years. We can deal with most of unforeseen circumstances during transportation. Our packages strictly comply with international standards, which ensures that the products are in good condition when you receive them.

Our Service

SLon aims at "100% product qualification, 100% contract performance, 98% equipment operation, 100% customer satisfaction, and zero customer complaint". To achieve the goal, it has established an advanced quality management system integrating experiment, technological process advice, customized product, installation and commissioning, remote instruction, and regular visit. Whenever and Wherever the magnetic separator equipment goes wrong, its professional team will be sent to your plants as soon as possible. It's high quality and excellent service that SLon persists in.

Experiment Photos

Exhibition Photos

Exhibition Photos