Roller Magnetic Separator Mining Australia Thailand India for Haematite Ore ...

Fushun Ejet Magnetic Equipment Co., Ltd.- Type:Magnetic Separator

- Voltage:Based on Customer′s Local Requirment

- Weight:Based on Different Models

- Material:Rare Earth Magnent

- Material Feature:High Magnetic Intensity

- Certification:CE

Base Info

- Energy Saving:Energy Saving

- Warranty:1 Year

- Color:Grey

- Customized:Customized

- Condition:New

- Processing Capacity:as Required

- Brand Name:Jsyy

- Size:as Required

- Motor Power:as Required

- Transport Package:Export Packing

- Specification:ISO

- Trademark:JSYY

- Origin:Fushun, Liaoning, China

- HS Code:85051190

- Production Capacity:30sets,Month

Description

The magnets used in the High Intensity Permanent Magnetic Roll Separators and made of alloys of rare earth elements are more powerful as compared to other magnets.

High Intensity Permanent Magnetic Roll Separators generate forces on the magnetic roll due to their properties and special magnetic series.

The obtained high magnetic attraction forces have low magnetic sensitivity and therefore they make it possible to separate very fine low magnetic minerals with a high recovery.

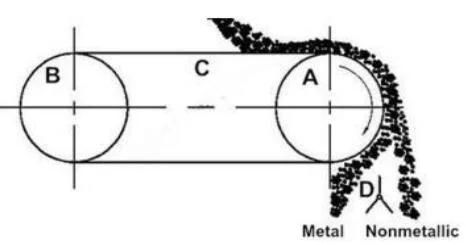

Dry Magnetic Roller SeparationDMS Series consists of permanent roll made of NdFeB disks A, idle roll(B), conveying thin belt(C), adjustable splitter(D). Operation of the separator is so simple that material to be treated is fed by the vibratory feeder onto conveying thin belt, magnetic particles are attracted to the roller and discharged into the metal chute, while non-magnetic particles are discharged from the roll into

the chute

Applications:

| 1.Industrial minerals |

| 2.Abrasive and refractory material |

| 3.Heavy mineral sand |

| 4 Food,medical, chemicals |

| 5.Plastic |

| 6.Ceramic and glass raw material |

| 7.Recycling material |

| 8.Metal and electronic waste |

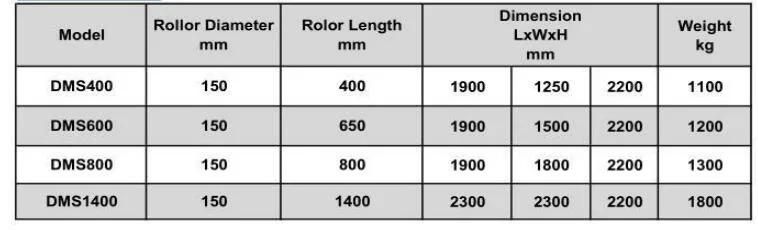

Specifications:

FAQ:

1. What is the MOQ of your machine?

A: Our MOQ is 1 set

2. How long is the machine warranty period?

A: the product warranty period is 12 months

In order to give you the responsible quotation, pls kindly inform us the following details:

1. What kind of material you are going to deal with?

2. What's the size of the materials?

3. What's the producing capacity you are going to achieve?

Most suitable machine would be recomended to you according to your informations.

Contact Us: