Coal Sawdust Charcoal Gypsum Powder Iron Ore Powder Mineral Powder Briquette Machine Ball ...

Gongyi Hengchang Metallurgical Building Material Equipments Plant- Pressing Mode:Hydraulic

- Product Shape:Oval Shape

- Motor Type:AC Motor

- Condition:New

- Name:Coal Sawdust Charcoal Gypsum Powder Iron Ore Powde

- Color:Client′s Required

Base Info

- Model NO.:YYQ

- Roller Diameter:500mm

- Roller Width:300mm

- Shaft Speed:15 R,Min

- Application:Coal,Chemical,Iron,Cowder

- Pressure From:Hydraulic

- Power(W):30,1.5 Kw

- Warranty:12 Months

- Capacity:5-9 T,H

- Power:30,1.5kw

- Roller Material:65mn

- Final Shape:Pillow,Round,Oval,

- Payment:T,T

- Delivery Time:15-20 Days

- Transport Package:International Universal Package

- Specification:According to customer needs

- Trademark:HC

- Origin:China Gongyi City, Henan Province

- HS Code:8463900010

- Production Capacity:5-10 T,H

Description

Basic Info.

Model NO. YYQ Roller Diameter 500mm Roller Width 300mm Shaft Speed 15 R/Min Application Coal/Chemical/Iron/Cowder Pressure From Hydraulic Power(W) 30/1.5 Kw Warranty 12 Months Capacity 5-9 T/H Power 30/1.5kw Roller Material 65mn Final Shape Pillow/Round/Oval/ Payment T/T Delivery Time 15-20 Days Transport Package International Universal Package Specification According to customer needs Trademark HC Origin China Gongyi City, Henan Province HS Code 8463900010 Production Capacity 5-10 T/HProduct Description

1.Product Application of Coal Sawdust Charcoal Gypsum Powder Iron Ore Powder Mineral Powder Briquette Machine Ball Press MachineA hydraulic high pressure briquette machine is a machine using a hydraulic cylinder to generate a compressive force. It uses the hydraulic equivalent of a mechanical lever. It is widely used in metallurgical, chemical, coal and refractories industries, suitable for wet powder briquetting, which is, adding an appropriate amount of water and other adhesives. This series machine uses a unique hydraulic system, improving the briquetting rate and strength. It is suitable for many materials such as light burning magnesium, iron oxide skin, manganese alloy, sludge, gypsum, carbon, silicon carbide, copper powder, iron powder and various refractory materials.

2.Working Principle of Coal Sawdust Charcoal Gypsum Powder Iron Ore Powder Mineral Powder Briquette Machine Ball Press Machine

The hydraulic briquette machine depends on Pascal's principle: the pressure throughout a closed system is constant. One part of the system is a piston acting as a pump, with modest mechanical force acting on a small cross-sectional area; the other part is a piston with a larger area which generates a correspondingly large mechanical force. Only small-diameter tubing (which more easily resists pressure) is needed if the pump is separated from the press cylinder. When the pressure on the press cylinder is released (the fluid returning to a reservoir), the force created in the press is reduced to a low value (which depends on the friction of the cylinder's seals).

3.Main Features of Coal Sawdust Charcoal Gypsum Powder Iron Ore Powder Mineral Powder Briquette Machine Ball Press Machine

(1) The machine uses a unique hydraulic system, enhanced the ball into the ball and into the ball strength.

(2) It is characterized by large molding pressure, the host speed adjustable, with a screw feeding device.

(3) pressure roller material wear, machine life long.

(4) for a wide range, such as activated carbon, coal, copper powder, iron powder, silicon and manganese alloy and a variety of refractories

(5) high security, the use of safe and reliable, saving manpower.

4.Technical Parameters of Coal Sawdust Charcoal Gypsum Powder Iron Ore Powder Mineral Powder Briquette Machine Ball Press Machine

| Model | Roller Dia. (mm) | Roller Width (mm) | Motor Power (kw) | Shaft Speed (r/min) | Reducer Model | Capacity (t/h) | Roller Material |

| YYQ-476 | 476 | 210 | 22/1.5 | 15 | ZQ500 | 3-6 | 65Mn |

| YYQ -476 | 476 | 260 | 30/1.5 | 15 | ZQ650 | 4-8 | 9Cr2M0 |

| YYQ -500 | 500 | 300 | 30/1.5 | 15 | ZQ650 | 5-9 | 65Mn/9Cr2M0 |

| YYQ -650 | 650 | 336 | 45/1.5 | 15 | ZQ750 | 8-15 | 65Mn |

| YYQ -672 | 672 | 275 | 75/1.5 | 13 | ZQ1000 | 8-15 | 9Cr2Mo |

| YYQ -750 | 750 | 400 | 55/1.5 | 13 | ZQ850 | 15-20 | 65Mn/9Cr2Mo |

| YYQ -850 | 850 | 500 | 75/1.5 | 10 | ZQ850 | 20-30 | 65Mn/9Cr2M0 |

| YYQ-1000 | 1000 | 650 | 110/1.5 | 10 | ZQ1000 | 30-50 | 65Mn/9Cr2M0 |

5.Our service

(1) Installation and guidance

When the machine arrives at your company, we will dispatch our technicians to your company to guide the installation and commissioning at site. User should pay for the following fees air tickets, boarding and lodging and traffic in client's factory.

(2)Technical training

We provide free technical training service to your stuff. Training content contains the main work principle of machine, operating regulations, maintenance methods and steps, safety, etc.

(3)Warranty:

Three guarantees of our product quality, warranty for one year (not include man-made damaged). We will maintain the machine for free for the quality problem. If the damage is caused by your improperly operation, the cost of the maintenance burden by you. we also provide you the life-long follow-up service.

6. Buying Guides

To choose the appropriate model for you ,can you tell me:

(1) What's the raw materials(such as coal ) ?

(2). What do you neeed ?a machine or a Briquette production line ?

(3). What's the required capacity( t/h)?

7.our copmany

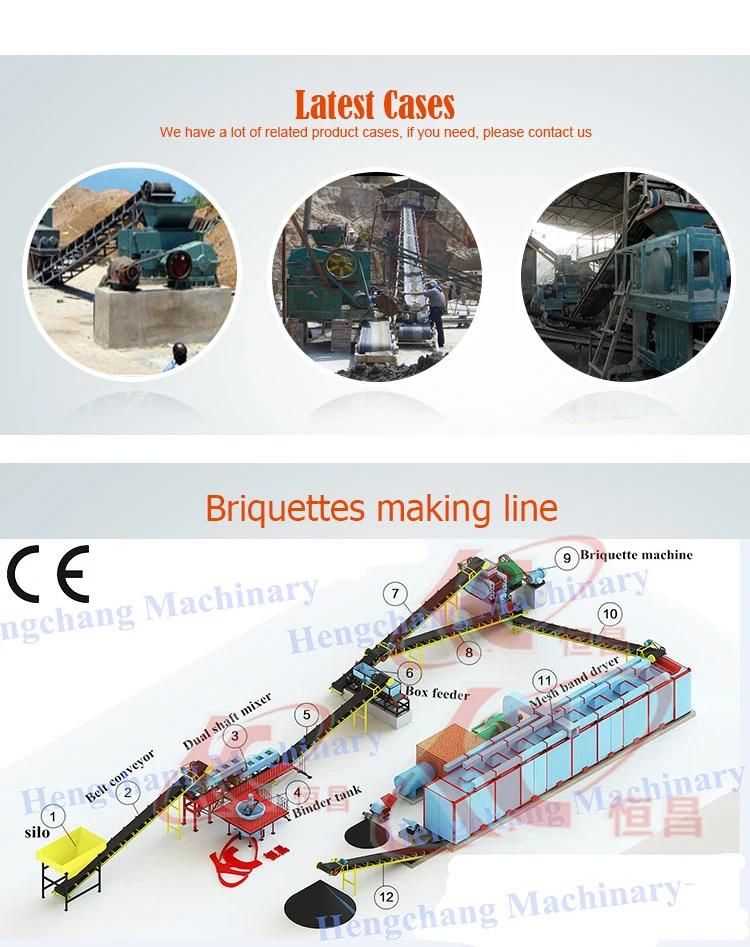

Gongyi Hengchang Metallurgy Building Material Equipments plant is a professional manufacturer specializing in the production of mineral beneficiation equipments, sand and stone crushing equipments, briquetting equipments, coal preparation equipments, drying and calcining equipments, cement plant equipments and compound fertilizer equipments.

Our company has high-quality products, sophisticated manufacturing process, caring after-sales service and improve its services. Products sold at home and abroad, and exports to Eastern Europe, the Middle East, the Americas, Africa, Southeast Asia and other countries. Praised by customers at home and abroad. Welcome friends from around the world to discuss business. Mutual benefit and common development.

FAQ:

1 Are you a trading company or manufacturer? What is your main products?

We are a manufacturer, Our factory name is Gongyi Hengchang metallurgical building materials equipments plant. which has over 25 years of experience in this industry. Our Main products are Jaw crusher,Impact crusher,Cone crusher,Hammer crusher,Vibration feeder,Vibration screen,sand/stone washing machine,ball mill,flotation machine,Disc pelletizer, concentrator,Rotary dryer,Conveyor machine ,Briquette machine , Mixer ,Roller grinder and so on,We produce products divided into Stone prodution line and Sand-making productiong line,

Magnetic separating process ,Flotation separating process ,Gravity separating process ,Coal and mineral powder briguetting .

2 Can I visit your factory and clients' workshop? How to get to your factory?

Yes, welcome to visit our factory anytime, we can also arrange your visit in our China clients' workshop.

For getting to our factory, you can get a flight to Zhengzhou Airport. It just takes about 2 hour from Zhengzhou Airport to our factory by car.

3 What is your guarantee time and aftersale service?

--Our guarantee time is 1 years.

--EEach order machine we provide installation drawing and operation manual. If needed, engineers can be sent to your factory for installation and commissioning, training.

--Any problem in operation or others about machines, we will give solution in 12-24hours.

4 What is your payment term?

We can accept various payment terms if it is convenient for you.

5 What is your delivery time?

machine leadtime is 7 working days in standard specification, 15~20 working days if customized.

Pls tell your questions,Hengchang factory team are happy to serve&ready to be your business partner! If you want to know more details, please contact Winni ! Your satisfaction is our greatest pursuit.

Contact:Amanda

Website: http://hcmining.en.made-in-china.com

Mobile: 0086 371 86106152