73 (2 7/8) with Nc23/Nc26 Drill Rod for HDD Machine

Wuxi Geotec Geological Equipment Co., Ltd.- Certification:ISO9001:2008

- Standard:JIS, API

- Surface Treatment:Forged One-Piece, Integral Type

- Manufacturing Process:Forging

- Material:Carbon Steel

- Condition:New

Base Info

- Model NO.:73(2 7,8) with NC23,NC26 drill rod for HDD machine

- Steel Grade:S135

- Thread:as Required

- Length:as Required

- Product Name:Horizontal Directional Drill, HDD Drill Pipes, Dri

- Drill Pipe Type:Forged One-Piece, Integral Type

- Usage:Drill Pipe for Horizontal Directional Drilling Mac

- Apply to Drill Machine Brand:Vermeer, Ditch Witch, Cash, American Auger and CH

- Transport Package:with Standard Export Package or According to Clien

- Specification:D24;D20;JT2020;JT3020;compatible with other hdd

- Trademark:CROWN

- Origin:China

- Production Capacity:5000PCS,Day

Description

Compatibility

Of Pipe

(mm)

(m)

(kg)

OD

(mm)

Female

Min

Clamp

Joint

Space

(mm)

Type

&

Quenching

Grade

Bend

Radius

(m)

Length

Of 90

Degrees

(m)

Bend

Angel

Max

Bend

Slope

Ratio

%

(KN.m)

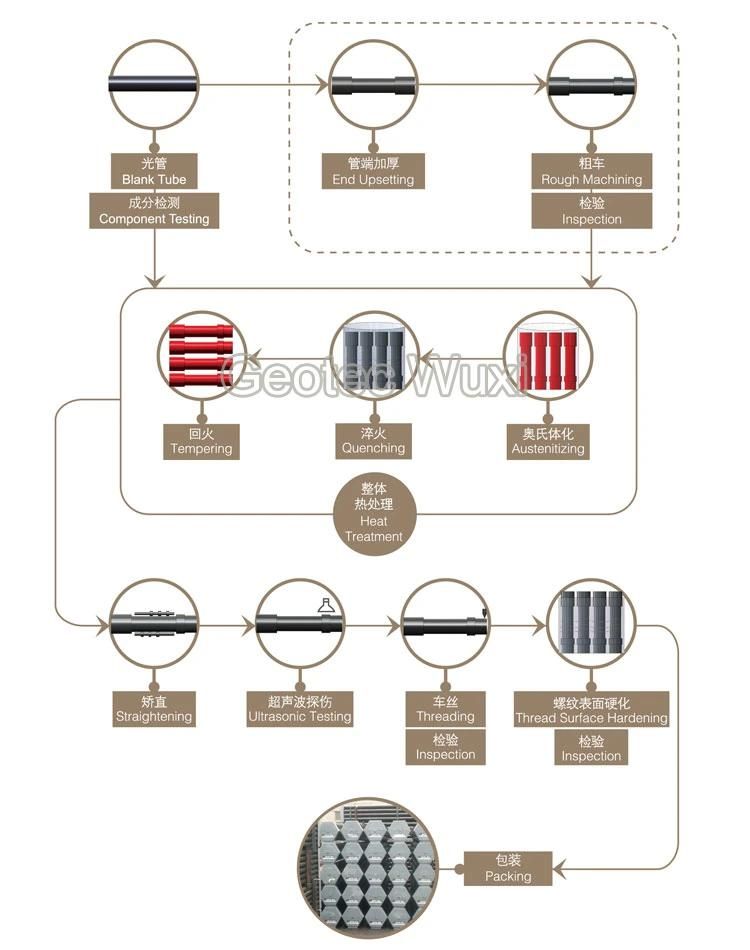

Production Procedure Of Drill Rod

Other Products

We specialized in manufacturing HDD Drill pipes/rods(forged one piece),

HDD Friction Welding Drill Pipe, HDD Drilling Tools, such as: sub saver& Drive chuck, swivel, pilot,

guide plate, pull tabs, barrel reamer, fluted reamer, fly cutter reamer/ three wing reamer, thread nut,

oct adapter, octagonal collar, D shackle/ clevis, anchor block, stabilizer, cutters, clamping jaw/chuck

jaw, roller bit, thread grease, heavy duty pipe wrench, tube wrench, and so on.

Quality Control

Quality guarantee is not only responsible for customers, but also the assurance of enterprise's

steady development. The necessary test equipment and the effective & perfect production

process control is the assurance of product quality. Taking the spirit of "To win the market

with innovation, to serve the customers with friendship, to build the brand with

quality, to develop the enterprise with sincerity", we utilize the advanced testing

methods to make each product meticulously.

Packaging & Shipping

With it's "high-quality, competitive price, variety complete and timely delivery",

GEOTEC WUXI has own the trust of many businessmen both from home and abroad.

GEOTEC WUXI has established a long-term friendly cooperative relations with many foreign

customers from more than 60 countries and regions, like Australia, Europe and the United

States, Asia, Africa etc., which will further explore the international market for the Company.

Company Information

Our company covers an area of 55 acres, and built a new modern plant covering more than

40,000 square meters. The manufacturing facility is located in Wuxi City which is very close

to Shanghai. With the unaided design capabilities and advanced flow of production, as well

as a whole set of high precision equipment, our high-quality products well favored by the

majority of customers. We have been striving to develop new and innovative products to

meet the changing needs of the drilling industry.

Company Honor

Q1. Where is your factory ?

A1: Our company's processing center is located in Wuxi, Jiangsu, China.

which is now the leading manufacturer of diamond core driling equipment and tools in China.

Q2. How do you control quality ?

A2: Mill Test Certification is supplied with shipment, Third Party Inspection is available.

Q3. What are the advantages of your company ?

A3: We have many professionals, technical personnel, more competitive prices and

best after-sales service than other companies.

Q4. Can you arrange the shipment ?

A4: Sure we can help you with the shipment. We have forwarders who have cooperated

with us for many years.

Q5. How about the delivery time ?

A5: It is based on the order, normally within 3 days after receiving your advance payment.

Q6. Can you provide sample ?

A6: Small samples in store and can provide the samples for free.

Customized samples will take about 2-3days.