Sawtooth Wave Jig Machine for Gold

Jiangxi Victor International Mining Equipment Co., Ltd.- Type:Gravity Separator

- Voltage:Customizable

- Weight:5T

- Material:Carbon Steel

- Material Feature:Wear Resistance

- Certification:ISO9001:2008

Base Info

- Model NO.:JT Series

- Energy Saving:Energy Saving

- Warranty:1 Year

- Color:Customizable

- Customized:Customized

- Condition:New

- Max Feeding Size:25mm

- Capacity:3-25t,H

- Motor:1.5-7.5kw

- Transport Package:No Packaging

- Specification:1530*780*1550mm

- Trademark:WKD

- Origin:China

- HS Code:8474100000

- Production Capacity:900 Sets Per Month

Description

Basic Info.

Model NO. JT Series Energy Saving Energy Saving Warranty 1 Year Color Customizable Customized Customized Condition New Max Feeding Size 25mm Capacity 3-25t/H Motor 1.5-7.5kw Transport Package No Packaging Specification 1530*780*1550mm Trademark WKD Origin China HS Code 8474100000 Production Capacity 900 Sets Per MonthProduct Description

Sawtooth Wave Jig Machine For GoldProduct Introduction

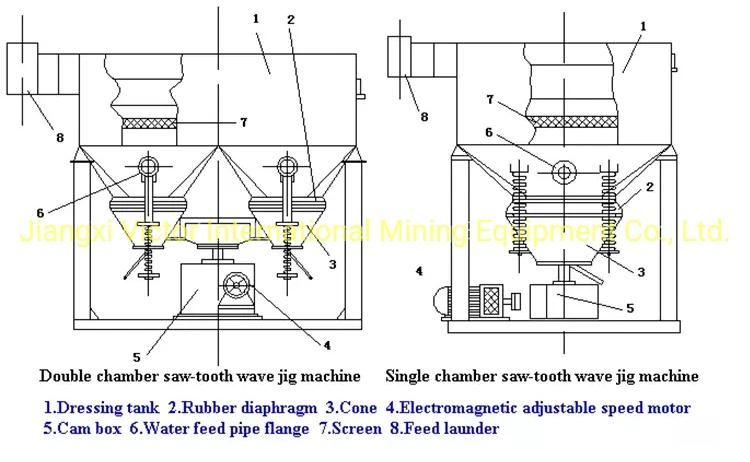

Jig Machine is a separation machine with deep tank, which is developed according to the law of layer theory of jigger bed stratification, and on the basis of traditional jigger. The performance of jigging machine has reached the domestic advanced level, and is one of the ideal devices in energy-saving gravity separation. When processing the open-pit mines, the jigging machine is a key machine with the principle of gravity separation. jigging machine pulse curve is like saw-tooth waveform to make rising water faster than the dropping water; enhanced the loose of bed, eased the inhaled role, so that heavy particles in the mineral can fully settlement, greatly improving the sorting capacity and recovery rate of equipment.

Working Principle

Jig machines need water to work, and it loosens materials in vertical alternative water-flows, and it forms different layers of materials of different densities and discharges both layers from up and down discharging ports separately. The basic composition of jigger is jigging chambers, also called jigging boxes, and there are screens in each chamber.

Water and raw ore will be fed from one end of the jigger screen, the ore granules will move in the vertical alternative water-flows. Layers will be formed because of density difference of materials. The minerals with small density will be in the up layer and will flow together with the up pulp flow while material with bigger density will be in the down layer and will discharged from the down discharging port as jigging concentrate.

This jig machine Can achieve a good result in processing such as placer gold, diamond, tungsten, iron, tin, hematite, cope, tantalum-niobium, titanium, manganese, barite, zirconium, chrome and gemstone etc.

Main Structure

Technical Parameters

| Model | Cham shape | Ber Area m2 | feeding size(mm) | Water added | Water pressure(Mpa) | Capacity | Power(kw) | Dimension (mm) | Weight(kg) |

| JT-0.57 | Ladder | 0.57 | <15 | 5~20 | >0.5 | 1~2 | 1.5 | 1530*780*1550 | 610 |

| JT1-1 | Ladder | 1 | <20 | 8~25 | >0.5 | 2~3 | 2.2 | 2060*1112*1890 | 900 |

| JT2-2 | Rect | 2.28 | <20,screen on top<60 | 35~50 50~65 | >0.5 | 7.5~10 7.5~15 | 3 single motor 2.2*2 dual motor | 2870*1520*1880 | 1640 |

| JT3-1 | Ladder | 3.3 | <20 | 35~50 | >0.5 | 10~15 | 5.5 | 2662*2000*3030 | 3085 |

| JT4-2 | Rect | 4.86 | <20,screen on top<60 | 50~65 65~80 | >0.5 | 15~20 15~30 | 7.5 single motor 5.5*2 dual motor | 4240*1990*2750 | 3500 |

| JT5-2 | Ladder | 5 | <20,screen on top<60 | 50~65 65~80 | >0.5 | 16~23 16~33 | 7.5 single motor 5.5*2 dual motor | 3940*2006*2580 | 4500 |

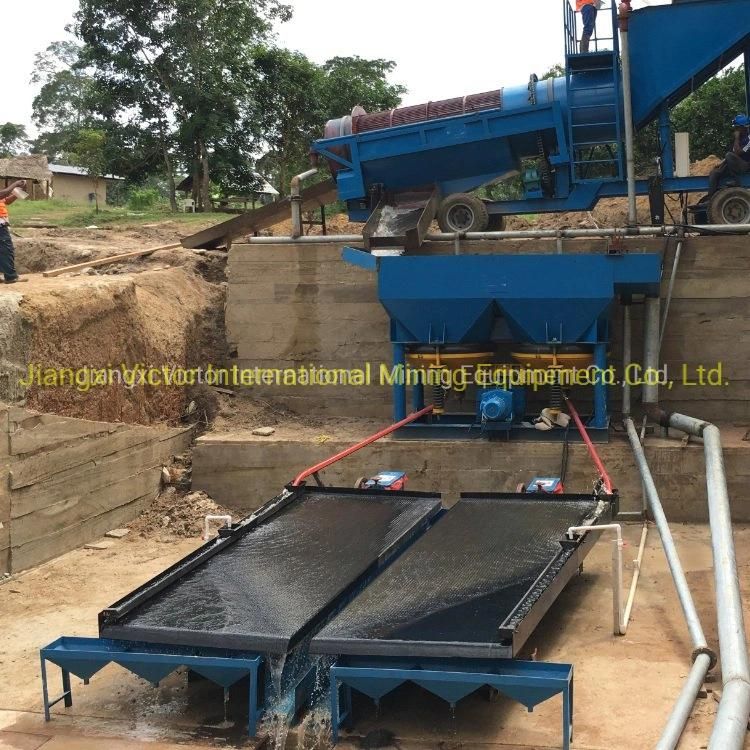

Mining Cases

Company Information

Jiangxi Victor International Mining Equipment Co.,Ltd is a large mineral processing manufacturer for 15 years history, with covering an area of 48,000 square meters and 20,000 square meters for workshop, with various large modernized machinery facilities, professional R&D team and installation team.

With 32% market share in China and the rest to overseas, already successfully exported to over 50 countries, such as USA, England, Australia, Brazil, Turkey, Italy, Russia, South Africa, Zimbabwe, Sudan, Ghana, Congo, Morocco, India,Indonesia, Malaysia, Philippines, North Korea, Mongolia, Vietnam, Thailand etc.

Our goal is to provide one-stop service for you and assist you to solve all problems from investment to his return in the field of mining, including the preliminary mineral analysis, mineral processing test, engineering design, equipment debugging and technical training etc..

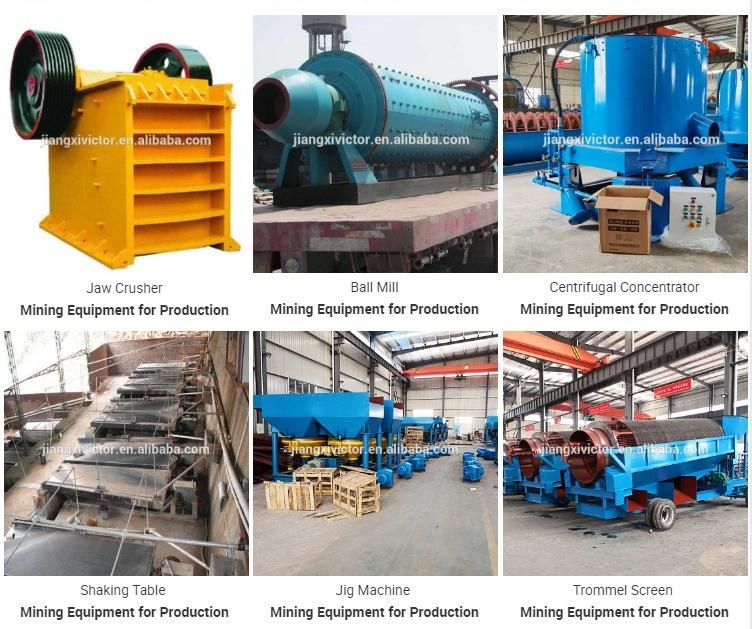

We are expert especially at mining separating and lab mining plant, main products as below:

Gold trommel wash plant

Shaking table

Spiral chute separator

Centrifugal gold concentrator

Jig separator machines

Waste recycling machine

Grinding and mill crusher

Flotation cell machine

Magnetic separator

Laboratory mining plant

Contact Us

Matthews Lai