Conveyor Chute Rubber Backed Ceramic Wear Liner

JIAOZUO DEBON TECHNOLOGY CO., LTD.- Certification:ISO 9001:2008, Qb

- Standard:Qb

- Surface Treatment:Without Processing

- Manufacturing Process:Vulcanizing

- Material:Alumina Ceramic and Rubber

- Description:Conveyor Chute Ceramic Wear Liner

Base Info

- Model NO.:DB-TCM

- Our Advantage:Ceramic Wear Liner Factory, High Quality

- Features of Ceramic Wear Liner:High Wear Resistance

- Process:Hot Vulcanizing Process

- Ceramic Tile:Al2O3>92% or 95% High Alumina Ceramics

- Rubber Matrix:Natural Rubber

- Poly Ceramic Liner:Polyurethane Ceramic Wear Liner Are Also Available

- Botton:with Steel Backing Plate or Cn Bonding Backed.

- Custom Ceramic Wear Liner:Available.

- Certificate:ISO9001:2008, SGS

- Transport Package:Pallet

- Specification:ISO9001: 2008

- Trademark:JZDB

- Origin:Jiaozuo, Henan, China

- HS Code:69091200

- Production Capacity:2000PCS,Month

Description

Basic Info.

Model NO. DB-TCM Our Advantage Ceramic Wear Liner Factory, High Quality Features of Ceramic Wear Liner High Wear Resistance Process Hot Vulcanizing Process Ceramic Tile Al2O3>92% or 95% High Alumina Ceramics Rubber Matrix Natural Rubber Poly Ceramic Liner Polyurethane Ceramic Wear Liner Are Also Available Botton with Steel Backing Plate or Cn Bonding Backed. Custom Ceramic Wear Liner Available. Certificate ISO9001:2008, SGS Transport Package Pallet Specification ISO9001: 2008 Trademark JZDB Origin Jiaozuo, Henan, China HS Code 69091200 Production Capacity 2000PCS/MonthProduct Description

Conveyor Chute Rubber Backed Ceramic Wear LinerOur Advantages:

1. Ceramic wear liner factory, high quality and low prices.

2.Excellent bonding between ceramic tiles and rubber, rubber and steel backing plate.

3.Complete ceramic wear liners for your options.

4. Strict QC/QA

About Conveyor Chute Ceramic Wear Liner:

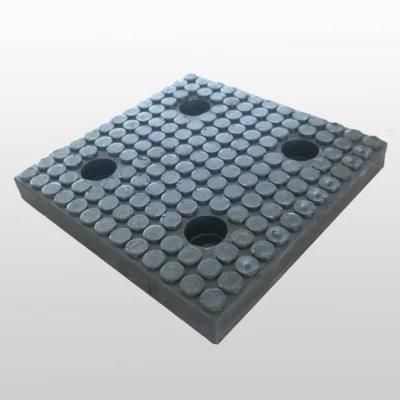

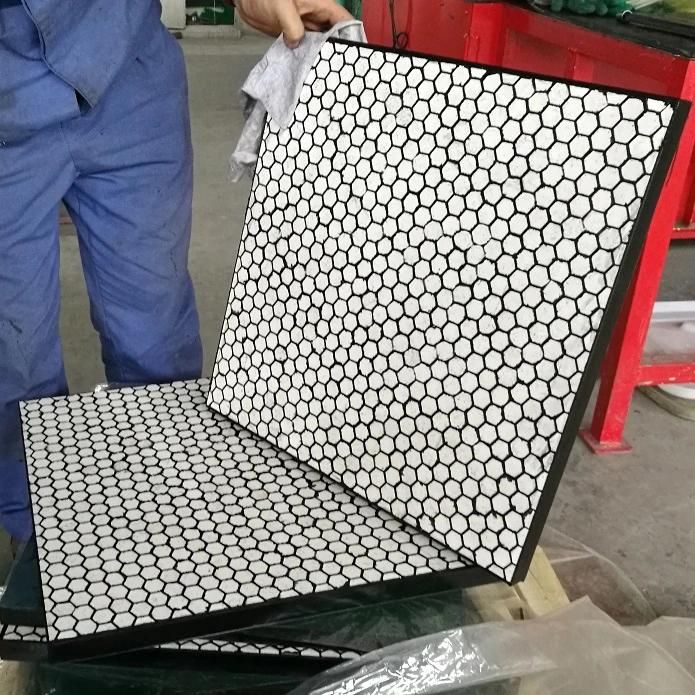

Ceramic wear liner, also called ceramic rubber wear liner, ceramic wear plate, is made of high alumina ceramics, rubber and steel backing plate/cn bonding layer, 3 kinds of material are vulcanized together by hot vulcanizing process.

Ceramic wear liner is a combination of high alumina ceramics and rubber, ceramic tiles deliver excellent wear resistance and elastic rubber help absorb impact energy.

Features of ceramic wear liners:

1. Ceramic wear liner incorporates the wear-risistance and shock resistance, particularly apply to conveying systems.

2. The most outstanding advantage is its superior mechanical properties at high temperature, chemical resistance, resistance of oxidation at high temperature, wear resistance and low density (about 1/3 that of metal)

3.Ceramic wear liners can be produced according to the drawings provided by clients. Such as lining, leader, chain wheel, mould, nozzle, valve, packing ring, piston, axletree and some components in paper production.

4. And the Specification will be determined according to the drawings provided by clients.

5. Smooth surface to ensure good sliding properties and hard ceramics with average wear and powerful impact resistance. Our alumina ceramics are High hardness, Low density, Super abrasive, and Smooth surface.

Types of ceramic wear liners:

1. Ceramic wear liner with steel backing plate

-300x300x36mm

-500x500x30mm

-500x500x50mm

-custom ceramic wear liners as per drawing

2. Ceramic wear liner with cn bonding layer/bonding layer backed ceramic wear liner

-500x500x8mm

-500x500x10mm

-500x500x20mm

-500x500x25mm

-500x500x30mm

-custom ceramic wear liners

Packing of ceramic wear liners:

Ceramic wear liners will packed in cartons. Commonly, 2 pieces in 1 carton, and 48 cartons on 1 pallet.

| Name | Adhesive-connected ceramic& rubber liner |

| payment terms | L/C, T/T |

| Delivery time | within 20 days after order confirmed |