Hot Sale MB5X Pendulum Roller Grinding Mill

Evangel Industrial (Shanghai) Co., Ltd.- Type:Mobile Crusher

- Motor Type:AC Motor

- Motor Power:280kw

- Application:Mine

- Materials:Coal

- Outlet Size:150-300mm

Base Info

- Condition:New

- Specification:13300*3490*3450

- Origin:China

- Production Capacity:50

Description

Basic Info.

Condition New Specification 13300*3490*3450 Origin China Production Capacity 50Product Description

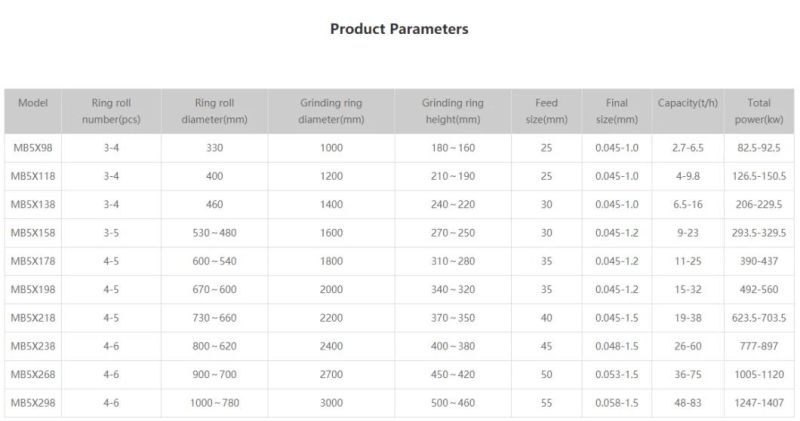

Hot sale MB5X Pendulum Roller Grinding Mill

According to accumulation and experimental analyses of on-site test data for more than thirty years, SBM, a Chinese grinding mill manufacturer, has researched and developed the fifth-generation pendulous hanging grinding mill - MB5X grinding mill. All non-combustible and non-explosive brittle mineral products whose Moh's hardness are below Grade 7 and water content below 6% could be ground by this grinding mill.

Hot Sale MB5X Pendulum Roller Grinding Mill Features :

Diluted Oil Lubricating Grinding Roller

Grinding roller of MB5X grinding mill adopts diluted oil lubrication. It is a technology initiated domestically which is maintenance-free and easy to operate. Diluted oil lubrication is oil bath lubrication, more convenient than grease lubrication since no frequent oil-adding, and it needs lower maintenance cost.

No Shovel Blade Cylinder

There is no shovel blade cylinder in the grinding chamber, so ventilation area is larger and air-conveying resistance is smaller. Besides, use of large-diameter grinding roller directly improves the efficiency of the grinding mill.

Volute Elastic Damping Structure

Volute elastic damping structure can effectively reduce vibrating damage on the grinding mill. Between the volute and engine base, special elastic structure is applied, and in combination with setup of rubber shock pad, it could directly avoid influence of vibration of engine base on operating stability of powder concentrator, and completely eradicate the problem of shatter crack of volute and central engine due to vibration of engine base.

Diluted Oil Lubrication

Main shaft of the grinding mill applies diluted self-lubricating system, which is fully automatic and labor-saving. The main-shaft bearing, transmission-shaft bearing and gear engagement surface are all lubricated and cooled by built-in oil pump. The operation is automatic without manual operation, which can timely and effectively ensure operating stability of the grinding mill.

Automatic Oil-Temperature Detecting Device

The reducer of the grinding mill is equipped with oil-temperature detecting system and heating unit, and according to the pre-set requirements, it could operate automatically under low temperature, ensuring the safe operation of host lubricating system.