Mill Liners and Wear Parts for Rolling Mills

Hunan Phohom New Material Technology Co., Ltd.- Type:Rolling Mills

- Motor Type:Rolling Mills

- Application:Metallurgy

- Place of Origin:Hunan, China (Mainland)

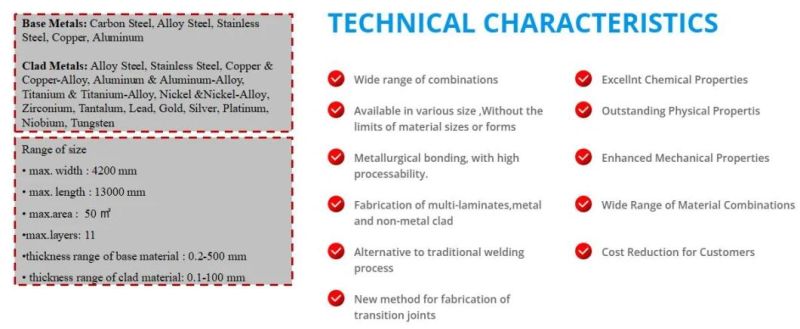

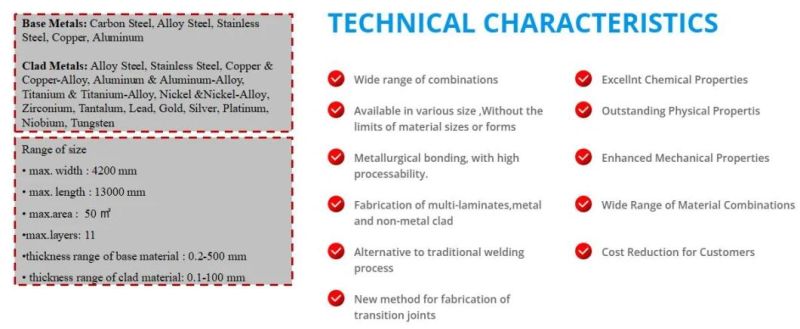

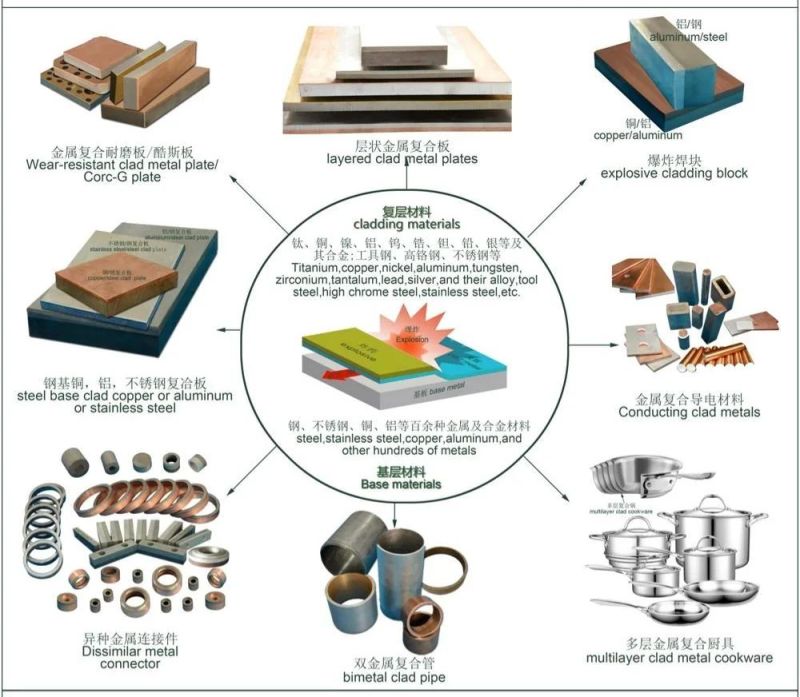

- Base Material:Steel

- Clad Metal:Bronze,Brass,Tin Bronze,Aluminum

Base Info

- Base Metal Thickness:0.5~500mm

- Model NO.:For industry

- Cladding Metal Thickness:0.5~50mm

- Product Type:Flat,Square,Rectangular

- HS Code:7210900000

Description

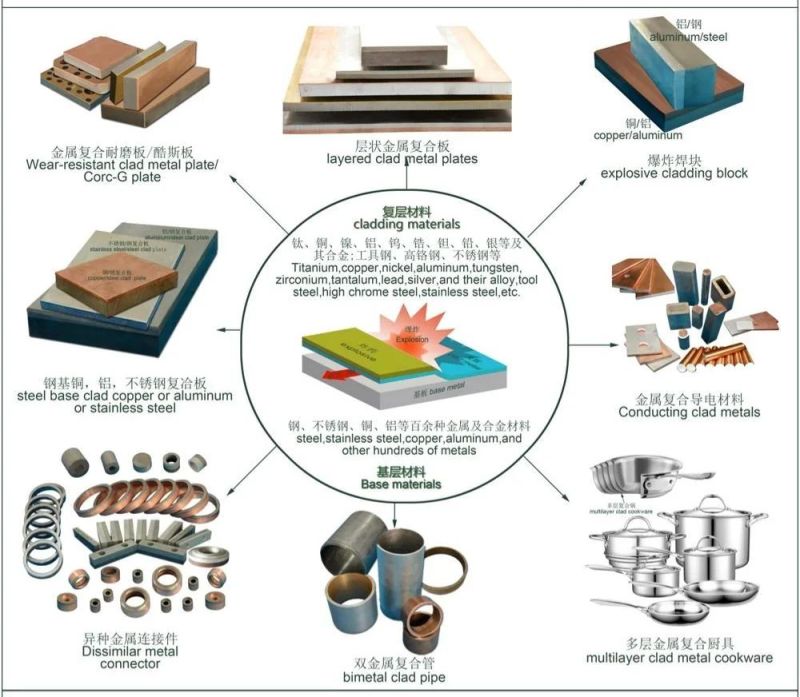

Product nameHigh quality wear plate for industry Standard Gb/t2968-90, astm, asme, ams, mil, jis, din,en Certificate Iso9001:2008 Material Copper-steel bimetallic self slide wear plate

Copper-steel bimetallic corrosion resistant plate

Tin bronze-steel clad wear plate

Aluminum bronze-steel clad wear plate

Becu-steel clad wear plate

Cobalt beryllium copper-steel clad wear plate

Zinc base alloy-steel clad wear plate

High chromium steel-steel clad plate

Chromium manganese steel-steel clad plate

High manganese steel-steel clad plate

High speed steel-steel clad wear plate die steel-steel wear plate

Tool steel-steel clad wear plate Size Cladding metal thickness:0.5~50mm

Base metal thickness:0.5~500mm

Sizes:Limited only by availability of materials and transportation restriction. Product type Flat plates(square/rectangular)

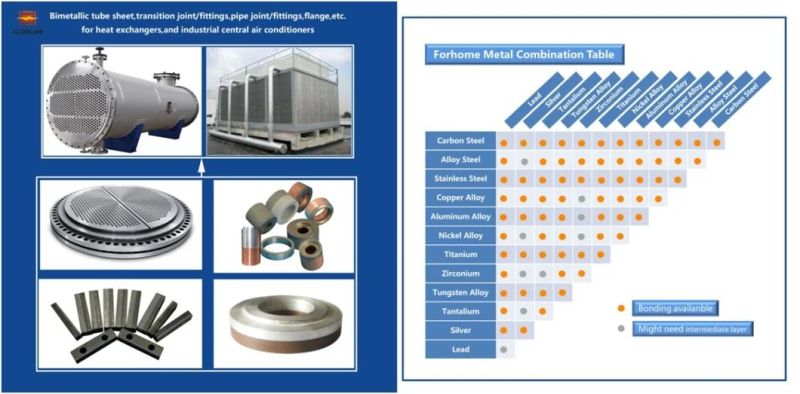

Round disc(head/tube sheets)

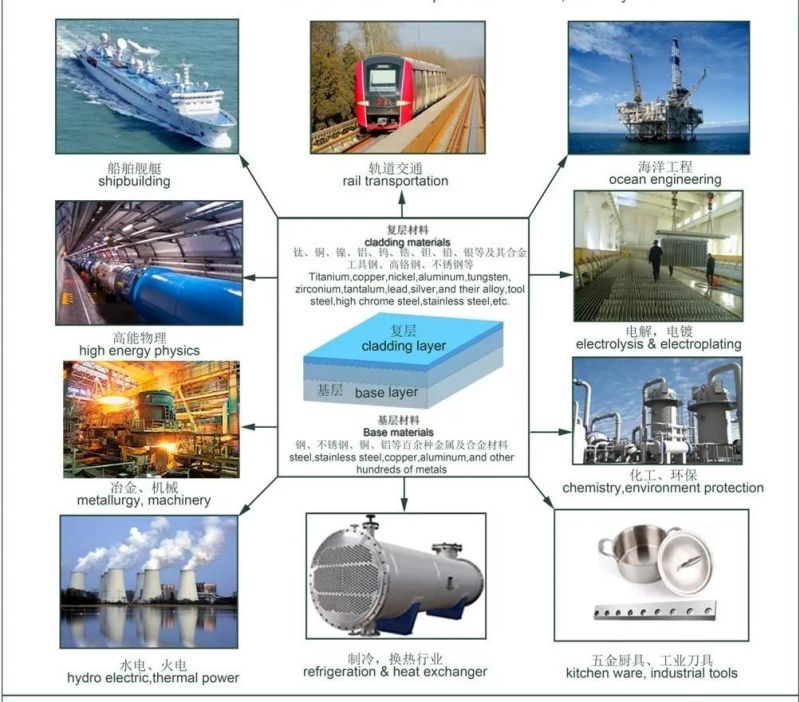

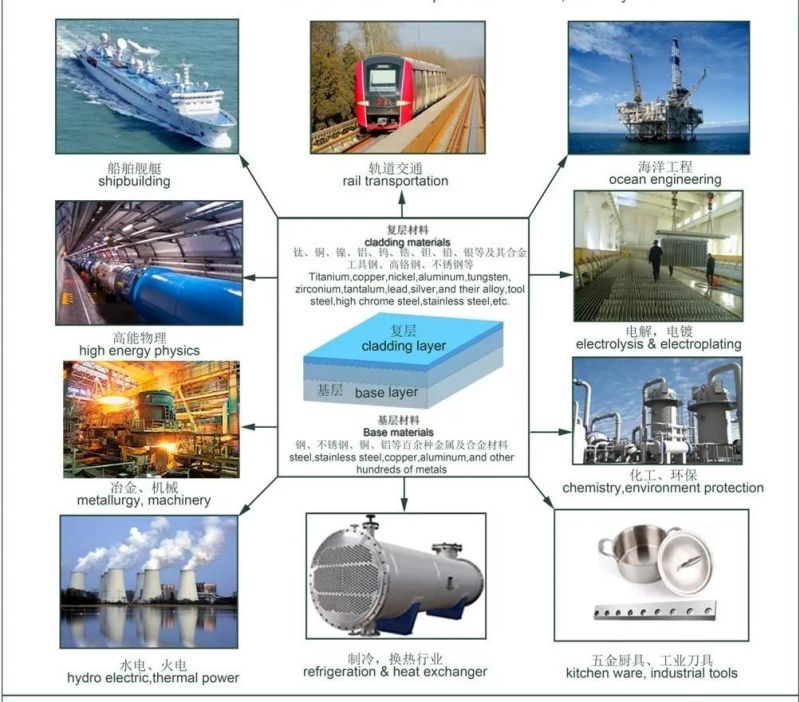

Pipes/lwn Application Industrial products

Industrial knives and shear blades

Metal fabricating and manufacturing knives

Bar and structural mill

Continuous caster

Hot strip mill

Plate/slab/blooming/billet/

Wire rod mill

Pickle line

Side trimmer

Mill liners and wear parts for rolling mills

Rotary pipe and tube cut-off

Slitter knives, slitter spacers

Slitter accessories

Machine ways, wear parts

Shear knives and shear blades for scrap

Demolition & waste recyclers

Knives for alligator shears, baler shears

Demolition shears and crushers

Hydraulic shears, mechanical shears

Rotary shredders and granulators Country of origin China Packing Per customers requirement Moq 100pcs Lead time 30-90days according quantity and requirement Payment method L/c, t/t,paypal, western union, escrow Trade term Fob, cif, cfr Port Shanghai, ningbo, guangzhou Service area Asia,north america,south america,europe,africa and oceania

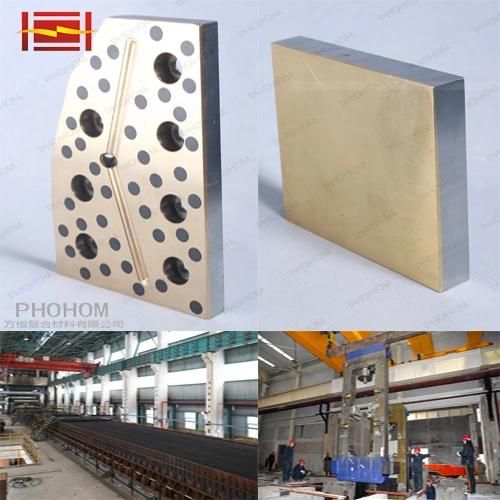

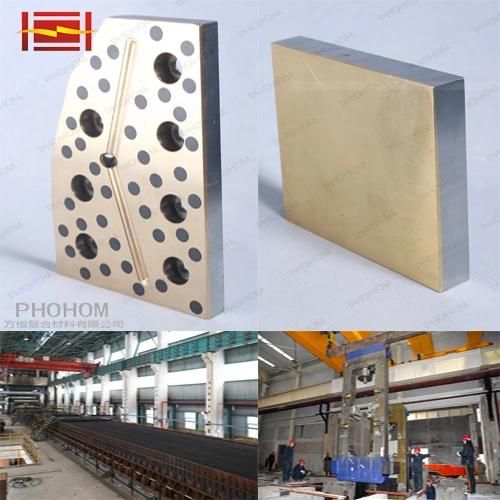

Picture

Specification

Material with high hardness and wear-resistance are selected as working face and material with impact-resistance and good resilience are chosen as base materials.The metal dynamic self-lubricating clad plate is provided with the abrasion resistance and self lubrication capacity with solid lubricant.Therefore, lubrication for maintenance is basically unnecessary during the operation.We can provide cooper alloy of different grades according to the working conditions.Our solution will save the copper alloy usage, reduce the production cost by more than 30%

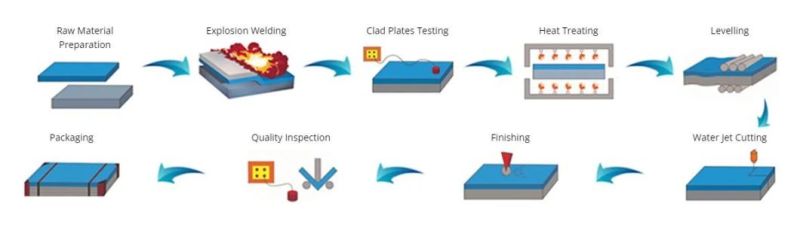

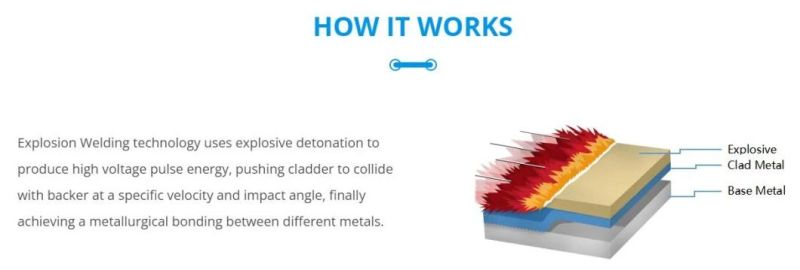

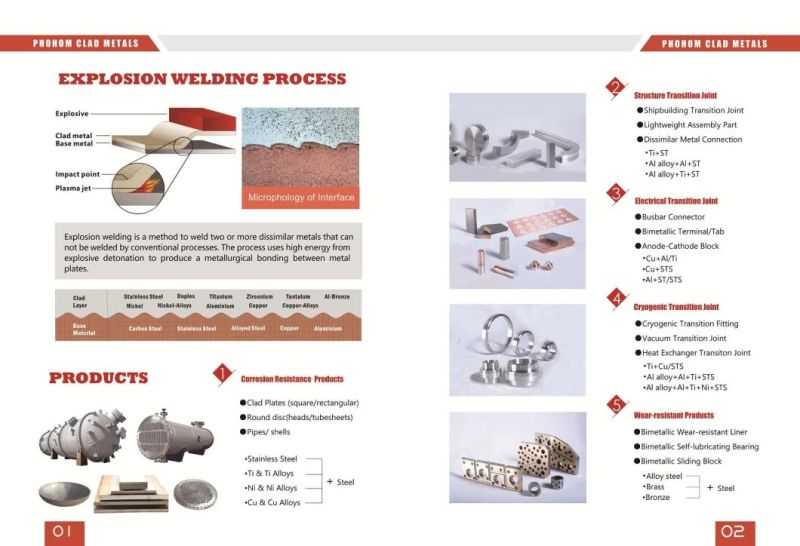

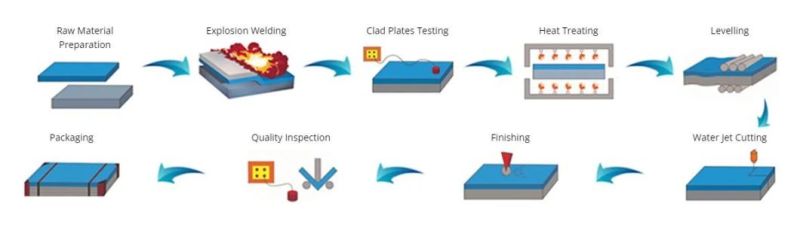

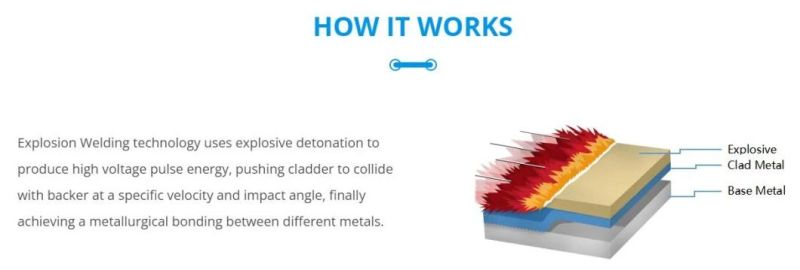

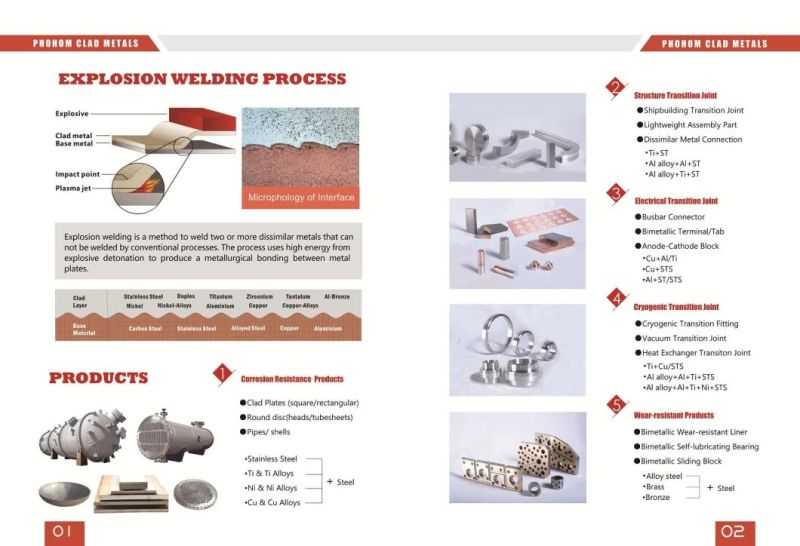

Wear-resistant bimetal clad metals/abrasion-proof materials/corc-g plates are plates used under large area abrasive wear conditions.Metals with high hardness and wear-resistance are selected as cladding working face;And metals with impact-resistance and good flexibility are chosen as base metals.Through explosive welding, these two different metals are firmly combined together.The thickness of wear-resistant clad layer is 1/3-1/2 of total clad metal thickness.When clad metals are working, the base metal will resist pressure, etc.Comprehensive properties;And the cladding layer can meet the wear-resistance under the working conditions.Metallurgical bonding between cladding and base metal ensures no distributed transverse crack, which is the most outstanding feature of explosion welding clad metals.

Advantages

1.100% explosive bonding rate;

2.Comprehensive properties of corrosion-resistant and resist pressure;

3.Improve the strength and reduce the cost;

4.Production size as customer requested.

Material series

Copper-steel bimetallic self slide wear plate

Copper-steel bimetallic corrosion resistant plate

Tin bronze-steel clad wear plate

Aluminum bronze-steel clad wear plate

Becu-steel clad wear plate

Cobalt beryllium copper-steel clad wear plate

Zinc base alloy-steel clad wear plate

High chromium steel-steel clad plate

Chromium manganese steel-steel clad plate

High manganese steel-steel clad plate

High speed steel-steel clad wear plate die steel-steel wear plate

Tool steel-steel clad wear plate

Application

Industrial products

Industrial knives and shear blades

Metal fabricating and manufacturing knives

Bar and structural mill

Continuous caster

Hot strip mill

Plate/slab/blooming/billet/

Wire rod mill

Pickle line

Side trimmer

Mill liners and wear parts for rolling mills

Rotary pipe and tube cut-off

Slitter knives, slitter spacers

Slitter accessories

Machine ways, wear parts

Shear knives and shear blades for scrap

Demolition & waste recyclers

Knives for alligator shears, baler shears

Demolition shears and crushers

Hydraulic shears, mechanical shears

Rotary shredders and granulators

Terms

Country of origin:China

Packing:Per customers requirement

Moq:1t

Lead time:30-90days according quantity and requirement

Payment method :L/c, t/t,paypal, western union, escrow

Trade term:Fob, cif, cfr

Port:Shanghai, ningbo, guangzhou

Contact

Website:phohomnewmaterial.en.made-in-china.com

Copper-steel bimetallic corrosion resistant plate

Tin bronze-steel clad wear plate

Aluminum bronze-steel clad wear plate

Becu-steel clad wear plate

Cobalt beryllium copper-steel clad wear plate

Zinc base alloy-steel clad wear plate

High chromium steel-steel clad plate

Chromium manganese steel-steel clad plate

High manganese steel-steel clad plate

High speed steel-steel clad wear plate die steel-steel wear plate

Tool steel-steel clad wear plate

Base metal thickness:0.5~500mm

Sizes:Limited only by availability of materials and transportation restriction.

Round disc(head/tube sheets)

Pipes/lwn

Industrial knives and shear blades

Metal fabricating and manufacturing knives

Bar and structural mill

Continuous caster

Hot strip mill

Plate/slab/blooming/billet/

Wire rod mill

Pickle line

Side trimmer

Mill liners and wear parts for rolling mills

Rotary pipe and tube cut-off

Slitter knives, slitter spacers

Slitter accessories

Machine ways, wear parts

Shear knives and shear blades for scrap

Demolition & waste recyclers

Knives for alligator shears, baler shears

Demolition shears and crushers

Hydraulic shears, mechanical shears

Rotary shredders and granulators

Picture

Specification

Material with high hardness and wear-resistance are selected as working face and material with impact-resistance and good resilience are chosen as base materials.The metal dynamic self-lubricating clad plate is provided with the abrasion resistance and self lubrication capacity with solid lubricant.Therefore, lubrication for maintenance is basically unnecessary during the operation.We can provide cooper alloy of different grades according to the working conditions.Our solution will save the copper alloy usage, reduce the production cost by more than 30%

Wear-resistant bimetal clad metals/abrasion-proof materials/corc-g plates are plates used under large area abrasive wear conditions.Metals with high hardness and wear-resistance are selected as cladding working face;And metals with impact-resistance and good flexibility are chosen as base metals.Through explosive welding, these two different metals are firmly combined together.The thickness of wear-resistant clad layer is 1/3-1/2 of total clad metal thickness.When clad metals are working, the base metal will resist pressure, etc.Comprehensive properties;And the cladding layer can meet the wear-resistance under the working conditions.Metallurgical bonding between cladding and base metal ensures no distributed transverse crack, which is the most outstanding feature of explosion welding clad metals.

Advantages

1.100% explosive bonding rate;

2.Comprehensive properties of corrosion-resistant and resist pressure;

3.Improve the strength and reduce the cost;

4.Production size as customer requested.

Material series

Copper-steel bimetallic self slide wear plate

Copper-steel bimetallic corrosion resistant plate

Tin bronze-steel clad wear plate

Aluminum bronze-steel clad wear plate

Becu-steel clad wear plate

Cobalt beryllium copper-steel clad wear plate

Zinc base alloy-steel clad wear plate

High chromium steel-steel clad plate

Chromium manganese steel-steel clad plate

High manganese steel-steel clad plate

High speed steel-steel clad wear plate die steel-steel wear plate

Tool steel-steel clad wear plate

Application

Industrial products

Industrial knives and shear blades

Metal fabricating and manufacturing knives

Bar and structural mill

Continuous caster

Hot strip mill

Plate/slab/blooming/billet/

Wire rod mill

Pickle line

Side trimmer

Mill liners and wear parts for rolling mills

Rotary pipe and tube cut-off

Slitter knives, slitter spacers

Slitter accessories

Machine ways, wear parts

Shear knives and shear blades for scrap

Demolition & waste recyclers

Knives for alligator shears, baler shears

Demolition shears and crushers

Hydraulic shears, mechanical shears

Rotary shredders and granulators

Terms

Country of origin:China

Packing:Per customers requirement

Moq:1t

Lead time:30-90days according quantity and requirement

Payment method :L/c, t/t,paypal, western union, escrow

Trade term:Fob, cif, cfr

Port:Shanghai, ningbo, guangzhou

Contact

Website:phohomnewmaterial.en.made-in-china.com