500bw 127dia 6205brg Rubber Disc Return Roller

Shandong Mingyang Conveyor Equipment Co., Ltd.- Type:Gravity Conveyor

- Structure:Roller Conveyor

- Material:Rubber

- Material Feature:Fire Resistant

- Certification:ISO9001:2008, ISO9001:2000

- Energy Saving:Energy Saving

Base Info

- Warranty:2 Years

- Color:Multi Color

- Customized:Customized

- Condition:New

- Origin:China

- HS Code:843139

- Production Capacity:17000

Description

Basic Info.

Warranty 2 Years Color Multi Color Customized Customized Condition New Origin China HS Code 843139 Production Capacity 17000Product Description

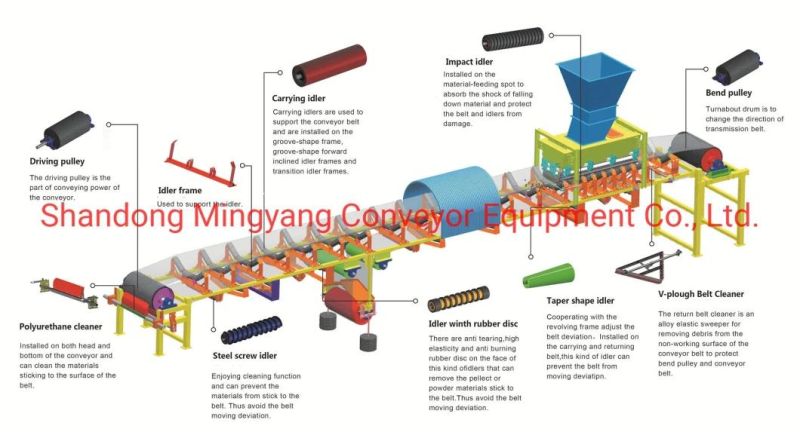

There are anti tearing,high elasticity and anti burning rubber disc on the face of this kind ofidlers that can remove the pellect or powder materials stick to the belt.Thus avoid the belt moving deviation.

Roller is an important part of belt conveyor, with many kinds and large quantity. The function is to support the belt, reduce the running resistance of the belt, and make the verticality of the belt not exceed a certain limit, so as to ensure the smooth operation of the belt.

The Rollers are classified into self-aligning Rollers, buffer Rollers, grooved Rollers and parallel Rollers according to their uses. The function of the self-aligning Roller is to correct the deviation of the belt conveyor. Usually, the rotary trough self-aligning Roller is installed on the heavy-duty section of the conveyor, and the parallel self-aligning Roller is installed on the no-load section. The buffer Roller is applied to the tailstock according to the actual situation. When receiving materials, it can reduce the impact of materials on the belt and is conducive to the service life along the long belt. The grooved Roller is generally composed of two side Rollers and one flat Roller, and the groove angle is generally 30 degrees. For the detachable belt conveyor, the three Rollers of the grooved Roller are hinged with each other, so it is called articulated Roller. The parallel Roller is generally a long roller, which is installed at the lower end under pressure, so it is called the lower Roller.

In terms of material, Roller is divided into steel and plastic Roller. There are three kinds of bearing seats of Roller: cast iron, steel plate stamping and phenolic plastic.

The sealing of Roller can be divided into steel and plastic. Their seals are internally filled with grease. The quality of Roller directly affects the power consumption of belt conveyor and the service life of belt. Therefore, reliable dust seal and good lubrication are important application standards.

Roller accounts for 35% of the total cost of a belt conveyor and produces more than 70% resistance, so the quality of Roller is particularly important.

standard

Impact of radial runout of Roller on belt conveyor: within the range of runout specified by the state, the belt conveyor can be kept running smoothly. Otherwise, the belt of belt conveyor will vibrate resonance, resulting in material spilling and environmental pollution. The higher the belt speed, the smaller the radial runout will be. The amount specified in China's national standard is 0.7mm and that specified in Japan's JIS standard is 0.5mm.

Influence of Roller flexibility on belt conveyor: during the operation of belt conveyor, the flexibility of Roller is very important. If the flexibility of Roller is poor and the rotation resistance coefficient is high, the whole belt conveyor system will have to pay more power and consume more power. Sometimes, the belt will be torn and the motor will be burned, More serious, it can cause a fire. Therefore, the selection of Rollers with low rotational resistance coefficient (preferably lower than 0.020) is an important content in the design and selection of belt conveyor.